Auxiliary explosion-proof system for coal mine air shaft

A technology of explosion-proof system and air well, which is applied in mine/tunnel ventilation, mining equipment, mining equipment, etc., and can solve the problems of high technical cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

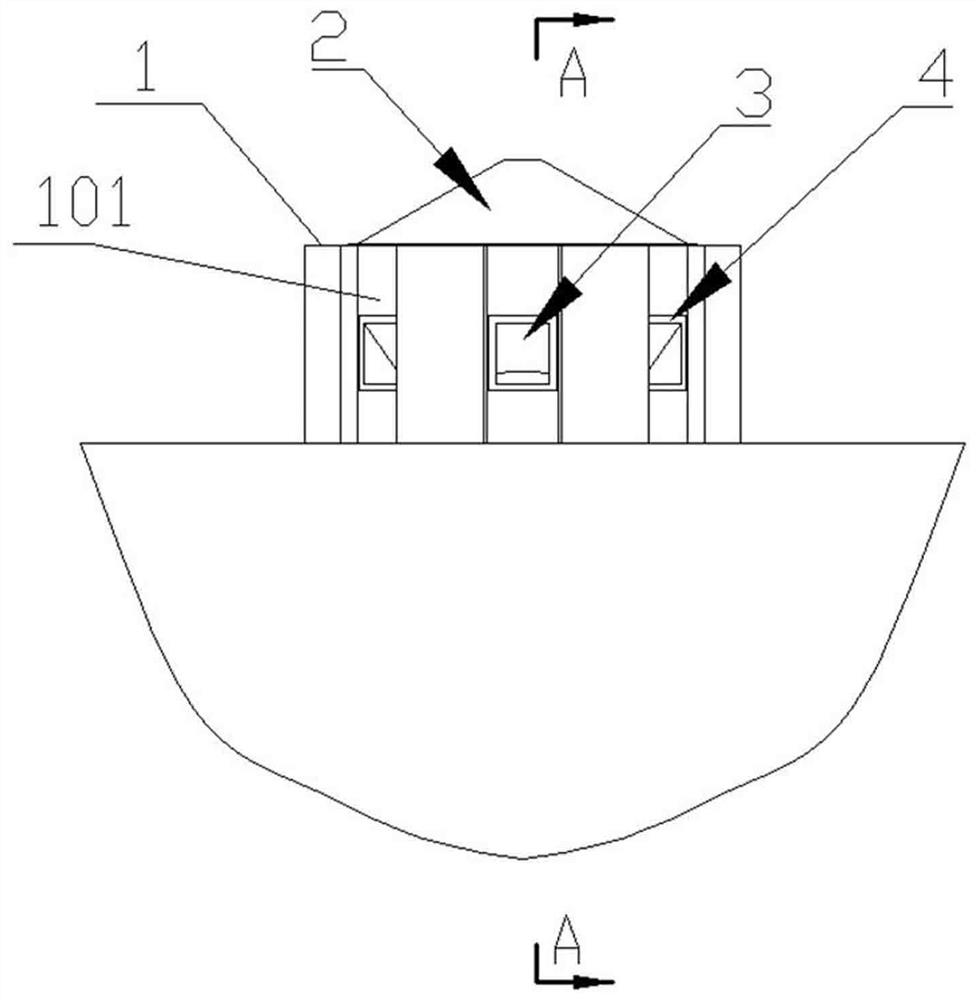

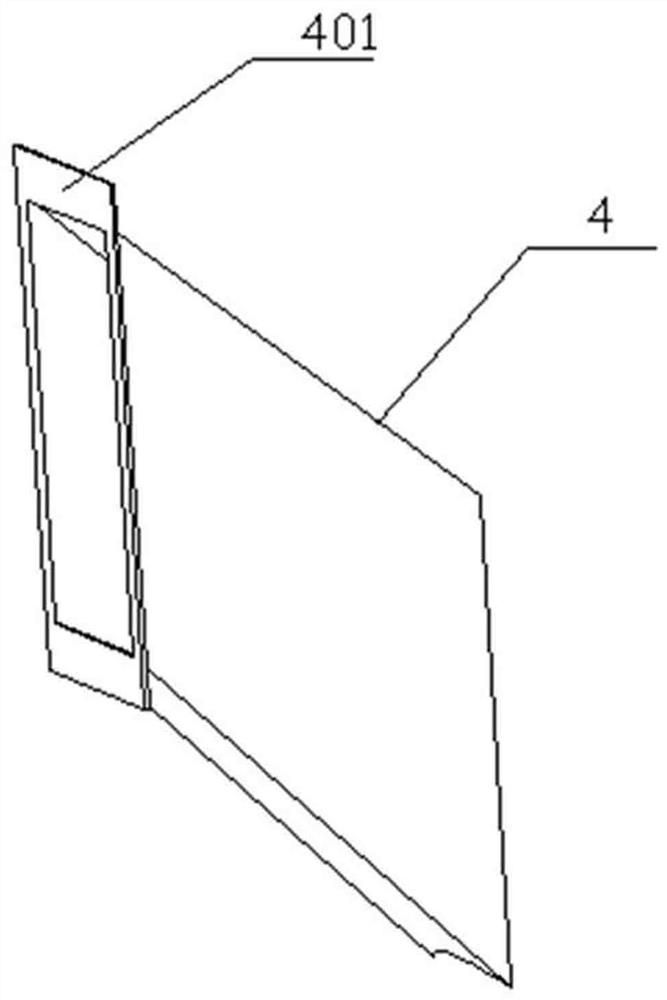

[0031] Such as Figure 1-8 The coal mine air shaft auxiliary explosion-proof system shown is arranged at the wellhead of the air shaft. A wellhead base 1 is arranged around the wellhead of the air shaft. The wellhead base 1 is cylindrical and made of reinforced concrete. The wellhead A main explosion-proof door 2 is installed on the upper end of the base body 1. The wellhead base body 1 protrudes upwards from the ground and extends a section of well wall 101. A number of auxiliary explosion-venting passages 3 are arranged at intervals on the well wall 101 in a circular array. The explosion passage 3 runs through the well wall 101, and the surface of the well wall 101 at the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com