Concrete column reinforcement structure and construction method thereof

A technology for concrete columns and reinforcing structures, applied in the directions of columns, piers, pillars, etc., can solve the problems of poor durability and unsuitable use of structural adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

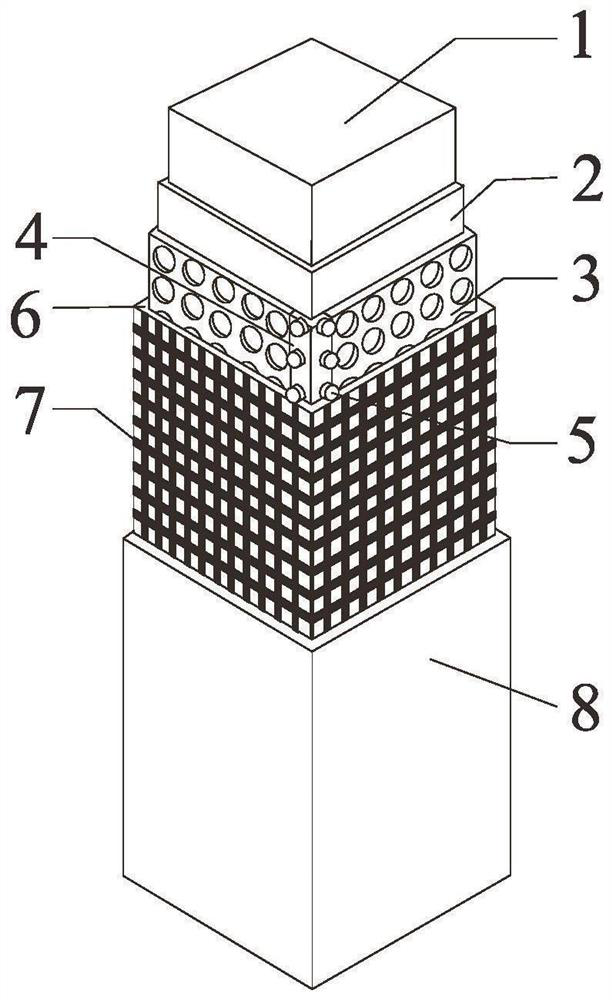

[0033] Such as figure 1 , 2 As shown, it is a concrete column reinforcement structure of the present invention, which includes a UHPC substrate layer 2, a densely porous steel plate 3, and a UHPC bonding layer that are sequentially coated on the side wall of a concrete column 1 with a rectangular cross section to be reinforced from the inside to the outside. 6. Fiber woven net 7 and UHPC protective layer 8, wherein, UHPC base layer 2 is sprayed on the side wall of concrete column 1 to be reinforced, and the thickness of UHPC base layer 2 is 10-15mm. In this embodiment, UHPC base layer 2 The thickness of the dense-porous steel plate 3 is a pair of L-shaped prefabricated panels, and the pair of L-shaped prefabricated panels are connected into a cylindrical shape and installed on the concrete column 1 to be reinforced coated with the UHPC matrix layer 2 and cling to the UHPC matrix layer 2 , the thickness of the densely porous steel plate 3 is 3 to 5mm. In the present embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com