Pretreatment method and application of acrylate assistant cross-linking agent, graft polymer of the acrylate assistant cross-linking agent and preparation method of the graft polymer

A technology of grafting polymer and acrylate, applied in the field of plastic material processing, can solve the problems of poor processing performance, complex production process, increased product density, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

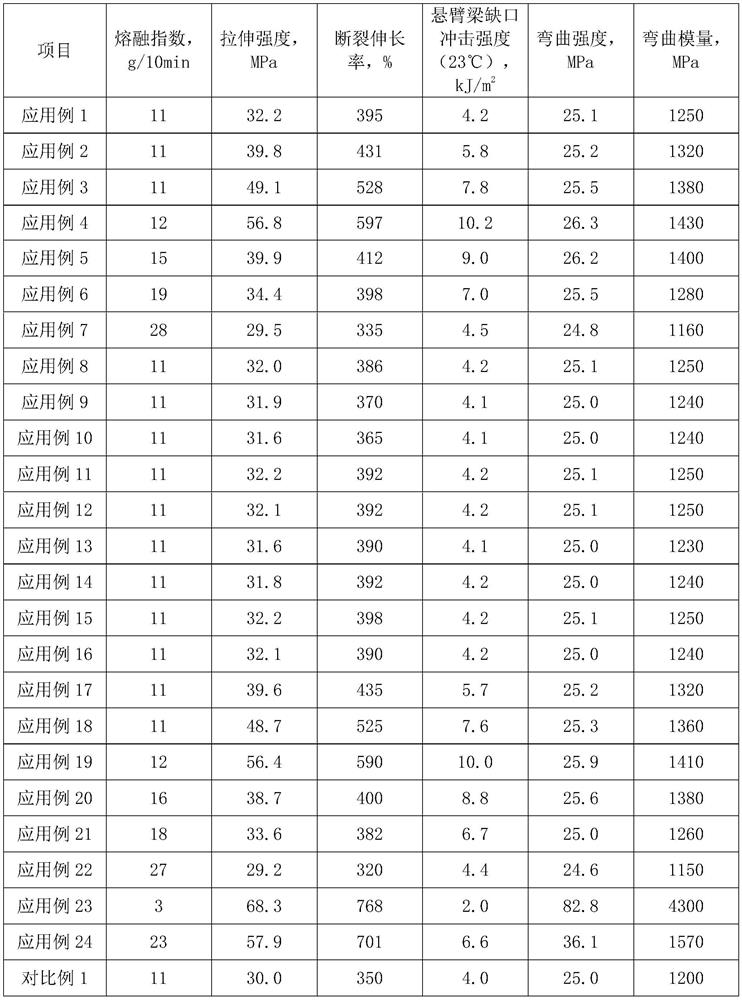

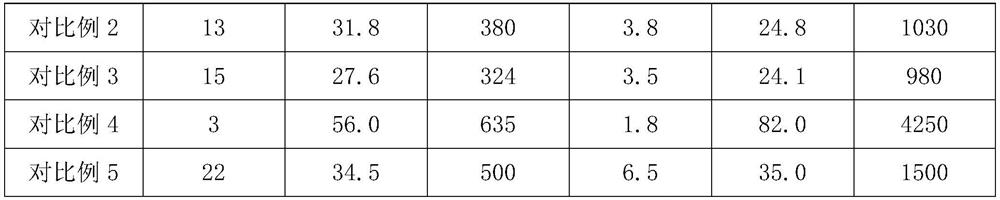

Examples

Embodiment 1

[0036] Embodiment 1: a kind of pretreatment method of acrylic acid salt auxiliary cross-linking agent: comprise the following steps: get 0.001kg tert-butyl hydroperoxide (TBHP), spray it on 100kg zinc acrylate, can obtain free-flowing The pretreatment acrylate-based co-crosslinking agent in the state of powder.

Embodiment 2

[0037] Embodiment 2: the difference between this embodiment and embodiment 1 is that the consumption of tert-butyl hydroperoxide is 0.1kg.

Embodiment 3

[0038] Embodiment 3: the difference between this embodiment and embodiment 1 is that the consumption of tert-butyl hydroperoxide is 1kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com