Cigarette factory sewage treatment and reclaimed water reuse treatment process

A technology of sewage treatment and treatment process, which is applied in the direction of flotation water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of low treatment efficiency, poor effluent quality, and poor stability of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

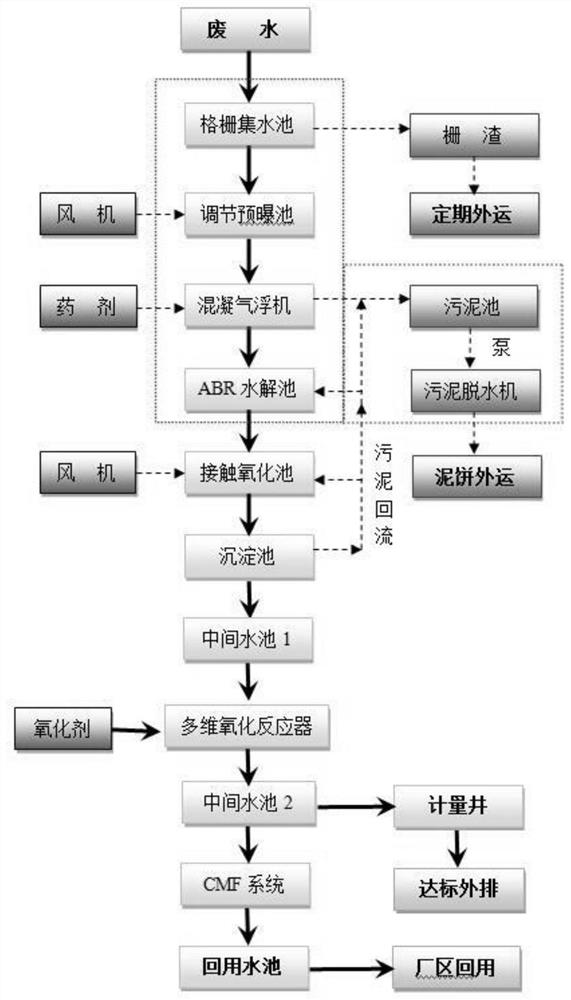

[0028] Such as figure 1 As shown, the present embodiment provides a cigarette factory sewage treatment and reclaimed water treatment process, including the following steps:

[0029] Step 1. After being collected by the pipe network, the sewage in the factory area enters the grille channel, and then flows into the sump automatically after removing large debris through the fully automatic mechanical grille in the grille channel;

[0030] Step 2. The sewage treated in step 1 is lifted by the pump and connected to the adjustment pre-aeration tank. The adjustment pre-aeration tank is equipped with aeration and stirring to fully adjust the water quality and water volume; the sewage in the adjustment pre-aeration tank is lifted by the pump into the coagulation air flotation machine according to the designed flow rate , adjust the pre-exposure tank to automatically control the liquid level through the ultrasonic liquid level gauge;

[0031] Step 3. The sewage is coagulated in the coa...

Embodiment 2

[0039] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0040] The sundries intercepted by the grid are collected in the grid slag hopper, and are transported out for disposal on a regular basis; the materialized sludge of the air flotation machine flows into the sludge tank; part of the sludge at the bottom of the sedimentation tank is returned to the ABR hydrolysis tank and the contact oxidation tank for sludge replenishment and The sludge is digested, and the remaining sludge at the bottom of the sedimentation tank is poured into the sludge tank. The sludge tank uses gravity to further concentrate the sludge, the supernatant is returned to the sump, the concentrated sludge is pumped into the sludge conditioning tank, a certain amount of PAM is added to adjust the sludge properties, and the conditioned sludge is pumped into the sludge tank. The mud dehydrator is used for dehydration, and the dehydrated mud cake is regularly transported out f...

Embodiment 3

[0042] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically;

[0043] It also includes hydrolysis and acidification treatment, wherein the hydrolysis and acidification tank is set before the contact oxidation tank, and part of the sedimentation tank sludge is returned to the hydrolysis and acidification tank. On the one hand, part of the carbon source organic matter can be consumed through denitrification through the backflow of the mixed solution. The function of the biological selector is beneficial to control the bulking of sludge; part of the sedimentation tank sludge is returned to the hydrolysis acidification tank to improve the treatment effect of the hydrolysis acidification tank, and can reduce the total amount of sludge treatment, and reduce the workload of mud cake and sludge transported abroad .

[0044] In step 7, before the sewage enters the CMF membrane system, it is filtered again through a 5-micron security filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com