Vehicle loader

A vehicle loader and vehicle technology, which can be applied to conveyor objects, transportation and packaging, loading/unloading, etc., and can solve problems such as low loading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

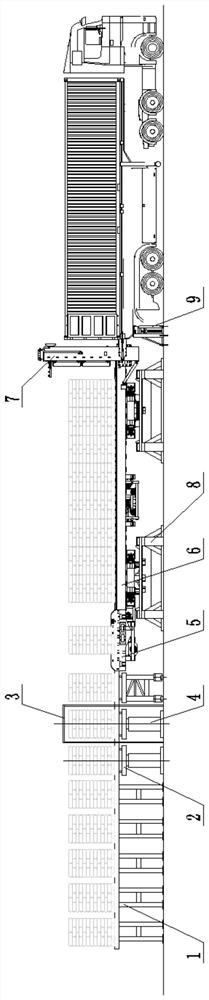

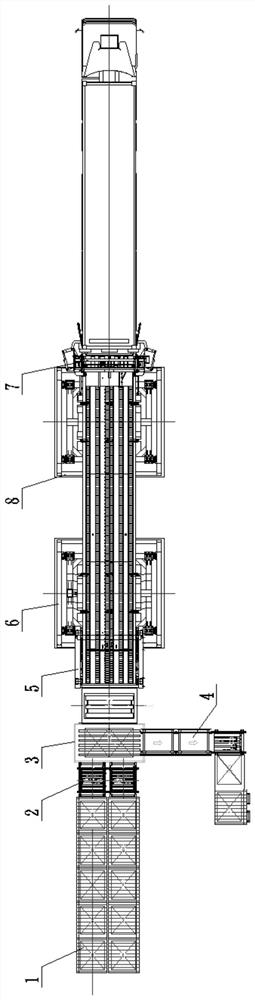

[0048] Specific embodiment one: reference Figure 1-Figure 30 To explain this embodiment, a complete vehicle loading machine of this embodiment includes a pallet conveying unit 1, a reshaping and stacking unit 2, a shape detection unit 3, an unqualified product roll-off unit 4, a stacking and marshalling unit 5, and a loading unit. The platform 6, the front door assembly 7, the adjustment mechanism 8, and the vehicle positioning device 9, the pallet conveying unit 1, the reshaping and stacking unit 2 and the unqualified product off-line unit 4 are arranged and installed in sequence, and the appearance detection unit 3 is installed on the unqualified product On the periphery of the off-line unit 4, the next process of the unqualified off-line unit 4 is equipped with a stacking and marshalling unit 5. The stacking and marshalling unit 5 is installed at one end of the loading platform 6, and the other end of the loading platform 6 is installed with a front door assembly 7 An adjust...

specific Embodiment approach 2

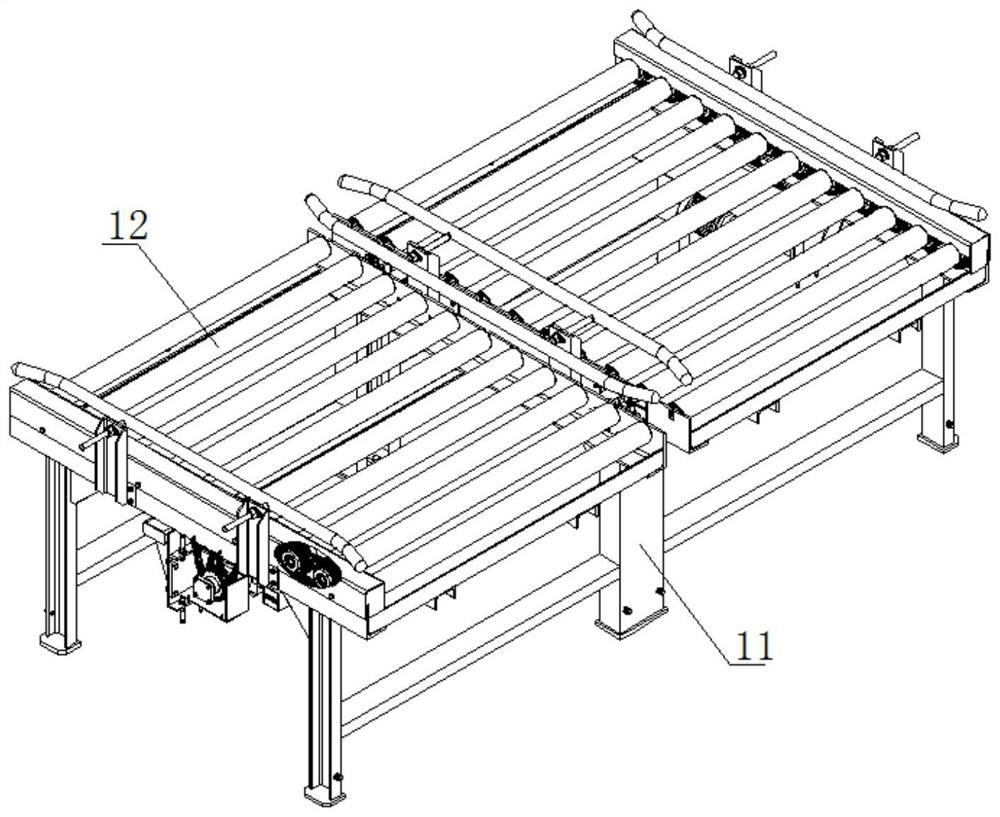

[0051] Specific embodiment two: reference image 3 To illustrate this embodiment, a complete vehicle loading machine of this embodiment, the pallet conveying unit 1 includes a pallet conveying frame 11 and a roller conveyor 12, and two pallet conveying frames 11 are installed A roller conveyor 12 arranged in parallel. With this arrangement, the pallet conveying unit 1 is used for conveying goods that need to be loaded into a vehicle, wherein the total width of the pile of goods conveyed by the roller conveyor 12 should be smaller than the inner width of the vehicle (the inner diameter of the carriage).

specific Embodiment approach 3

[0052] Specific embodiment three: reference Figure 4-Figure 9 To illustrate this embodiment, a complete vehicle loading machine of this embodiment, the shaping and stacking unit 2 includes two shaping adjustment units 21 with the same structure, the two shaping adjustment units 21 are arranged oppositely, and the shaping adjustment The unit 21 includes a lifting drive base 211, a first roller conveyor 212, a tightening transmission mechanism 213, a reshaping lifting motor 214, a reshaping lifting spindle assembly 215, and a reshaping lifting guide rail 216. The first roller conveyor 212 is installed on the lifting On the driving base 211, four shaping lifting guides 216 are fixedly installed on the lifting driving base 211, and the tightening transmission mechanism 213 is slidably installed on the shaping lifting guide 216. The lifting driving base 211 is equipped with a shaping lifting motor 214 and a shaping lifting spindle assembly. 215, the tightening transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com