Preparation process of enhanced fit mask

A preparation process and mask technology are applied in the field of the preparation process of reinforced fit masks, which can solve the problems of being difficult to slip off, affecting the air permeability and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

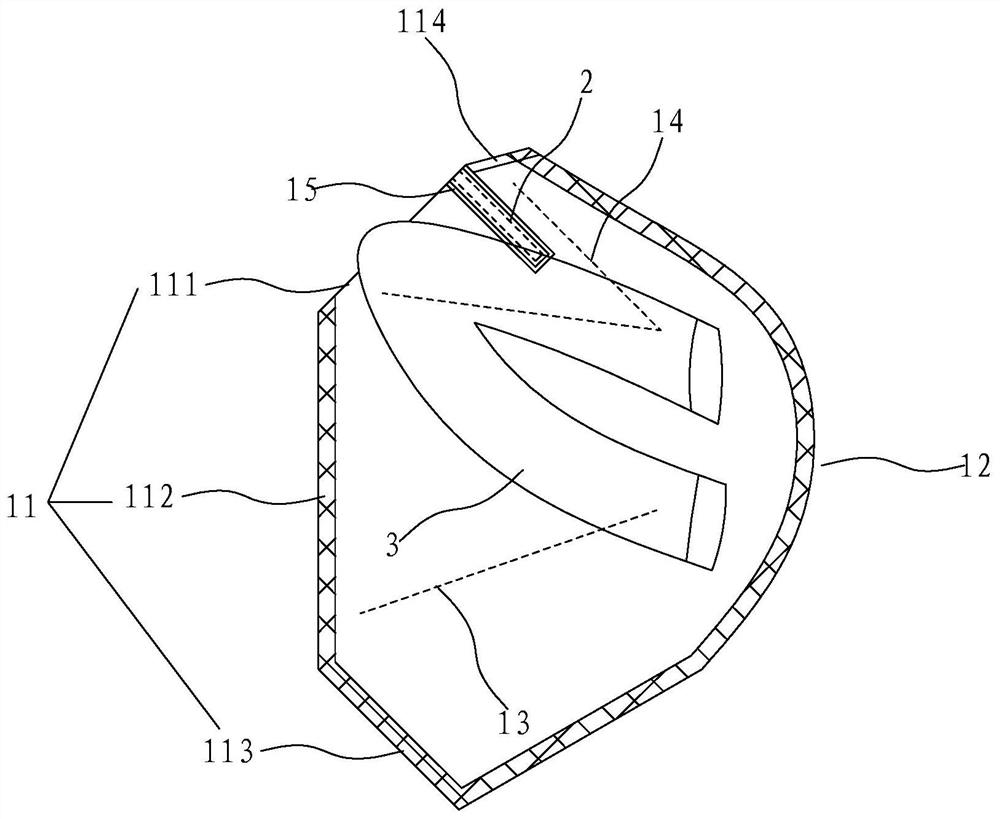

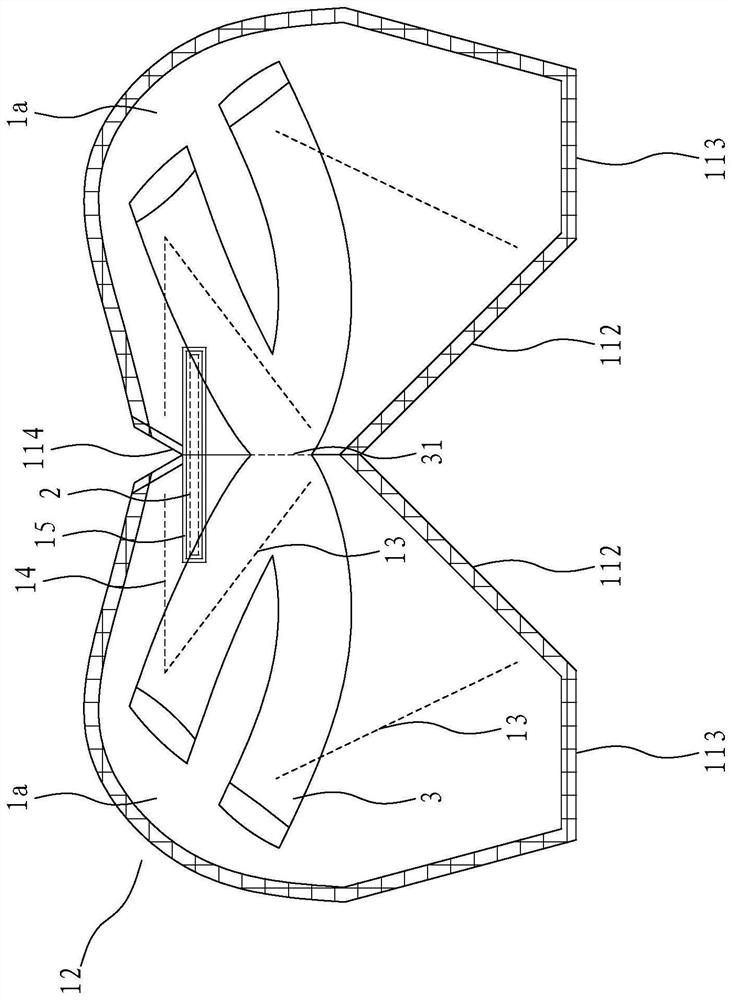

[0023] refer to figure 1 , 2 , 3, the present embodiment provides a kind of strengthen fit type mask, comprises mask body, the bridge of the nose bar 2 that is located in mask body, described mask body comprises closed end 11 and open end 12, and described mask body is made of two pieces The body 1a is joined and formed along the closed end, and the two outer sides of the open end 12 of the mask body are respectively provided with ear straps 3. The closed end 11 is composed of a nose area 111, a mouth area 112, and a chin area 113. The nose area 111, the mouth area 112, and the chin area 113 are respectively formed in a straight line, and the end of the nose area 111 away from the mouth area 112 is provided with a folded portion 114, and the folded portion The included angle between 114 and the nose area 111 is greater than 2 degrees and less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com