Concrete production equipment capable of switching stirring modes and production method

A technology for production equipment and concrete, applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of single mixing method and bottleneck in improving mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

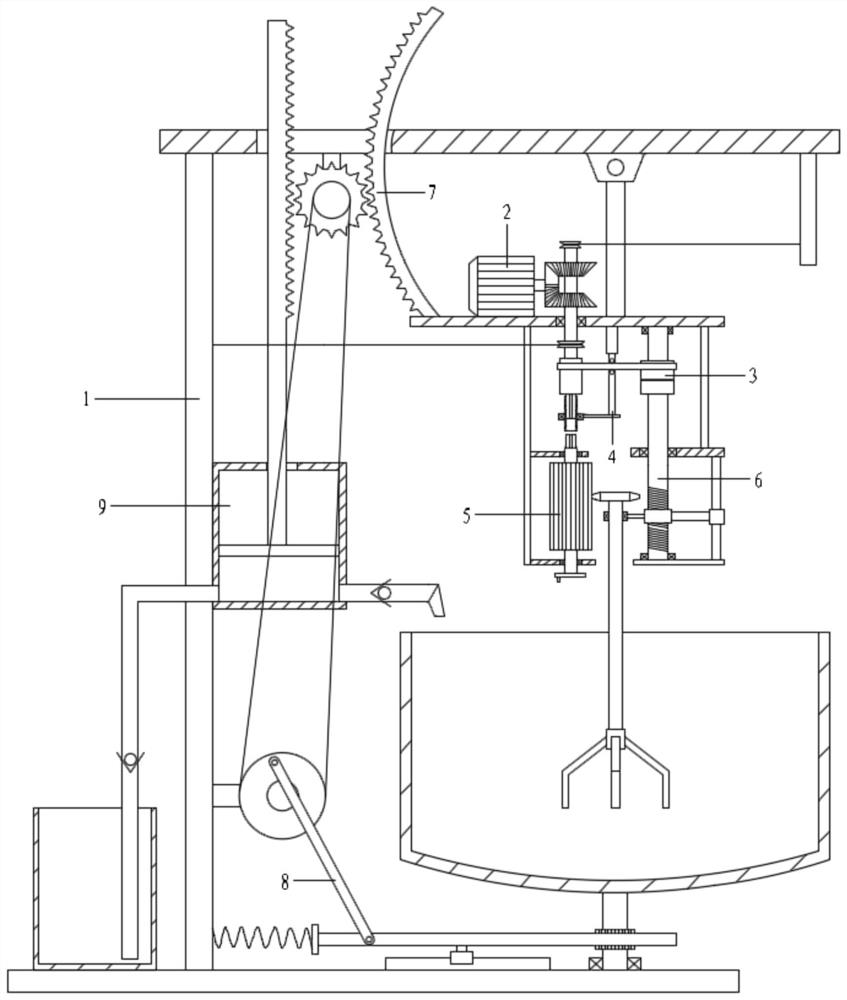

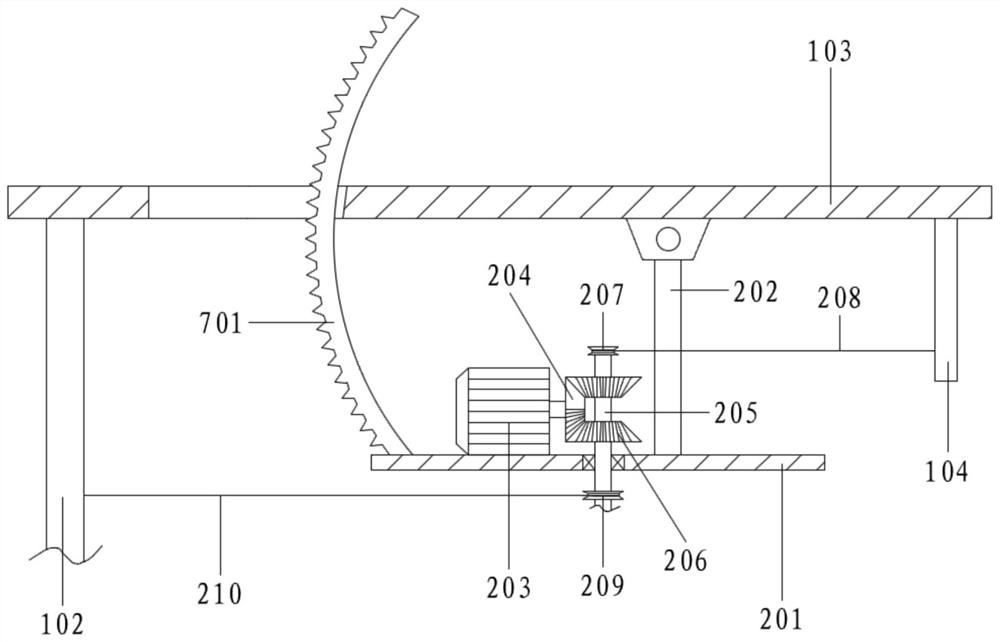

[0064] With reference to the accompanying drawings, a concrete production equipment capable of switching mixing methods includes a frame assembly 1, a swing assembly 2, a first-class transmission assembly 3, a switching assembly 4, a stirring assembly 5, a lifting assembly 6, a second-class transmission assembly 7 and a rotating component 8;

[0065] The frame assembly 1 includes a base plate 101, a left vertical plate 102, a top plate 103, a right end plate 104 and a mixing box 105; There is a right end plate 104; a stirring box 105 is arranged above the bottom plate 101; a swing assembly 2 is arranged below the top plate 103, and a type of transmission assembly 3 is arranged on the left side of the swing assembly 2; a rotating assembly 8 is arranged below the stirring box 105, and the swing assembly 2 passes through The first type of transmission assembly 3 and the rotation assembly 8 cooperate; the bottom of the swing assembly 2 is connected with the second type of transmis...

Embodiment 2

[0067] With reference to the accompanying drawings, a concrete production equipment capable of switching mixing methods includes a frame assembly 1, a swing assembly 2, a first-class transmission assembly 3, a switching assembly 4, a stirring assembly 5, a lifting assembly 6, a second-class transmission assembly 7 and a rotating component 8;

[0068] The frame assembly 1 includes a base plate 101, a left vertical plate 102, a top plate 103, a right end plate 104 and a mixing box 105; There is a right end plate 104; a stirring box 105 is arranged above the bottom plate 101; a swing assembly 2 is arranged below the top plate 103, and a type of transmission assembly 3 is arranged on the left side of the swing assembly 2; a rotating assembly 8 is arranged below the stirring box 105, and the swing assembly 2 passes through The first type of transmission assembly 3 and the rotation assembly 8 cooperate; the bottom of the swing assembly 2 is connected with the second type of transmis...

Embodiment 3

[0104] After the device is started, if additional water is to be added, it is necessary to manually refill the mixing tank 105, but there is a certain risk in such an operation. Add water operation.

[0105] It also includes a water adding assembly 9; the water adding assembly 9 includes a piston cavity 901, a piston plate 902, a lifting rack 903, a water adding pipe 904, a water suction pipe 905 and a water tank 906;

[0106] The piston cavity 901 is fixed on the left vertical plate 102, and the piston plate 902 moving up and down is housed in the piston cavity 901; the left side of the second driven gear 702 is equipped with a vertical lifting rack 903, and the bottom end of the lifting rack 903 extends into the The piston chamber 901 is connected to the piston plate 902; the bottom right side of the piston chamber 901 is connected with a water supply pipe 904, the outlet of the water supply pipe 904 faces the mixing tank 105, and the water supply pipe 904 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com