Automatic assembling equipment for automobile shock absorber

An automobile shock absorber and automatic assembly technology, which is applied to metal processing equipment, assembly machines, manufacturing tools, etc., can solve problems such as inability to assemble shock absorbers and no fixing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations.

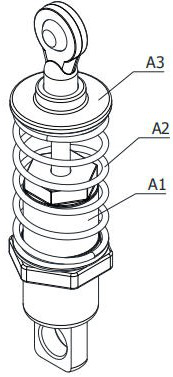

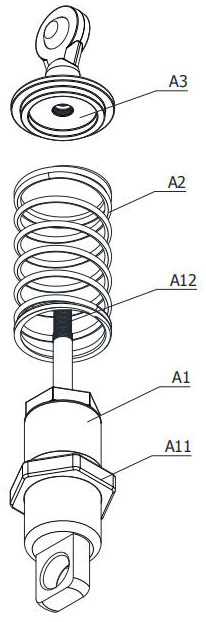

[0042] Reference figure 1 , figure 2 with image 3 As shown, an automatic assembly equipment for automobile shock absorbers is applied to the automatic assembly of shock absorbers. The shock absorber includes a damper A1, a spring A2, and an internally threaded spring cap A3. The damper A1 is coaxially provided with an adjusting nut A11 And the top of the output shaft is provided with a thread A12 for screwing with the internal thread spring cap A3. The assembly equipment includes:

[0043] The fixed workbench 1, in the working state, the output shaft of the damper A1 is arranged vertically upward on the fixed part of the fixed workbench 1;

[0044] The clamp-type damper conveyor belt 2 and the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com