An automatic production device for water inlet pipes

A technology for production devices and water inlet pipes, which is applied to measuring devices, metal processing equipment, instruments, etc., can solve the problems of unrelated assembly process and testing process, time-consuming and labor-intensive, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

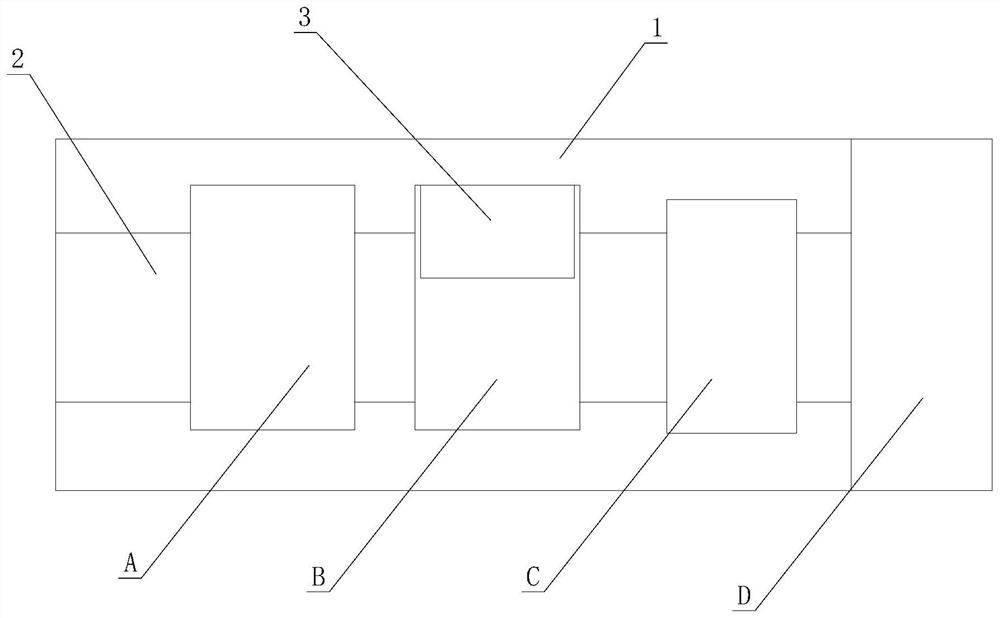

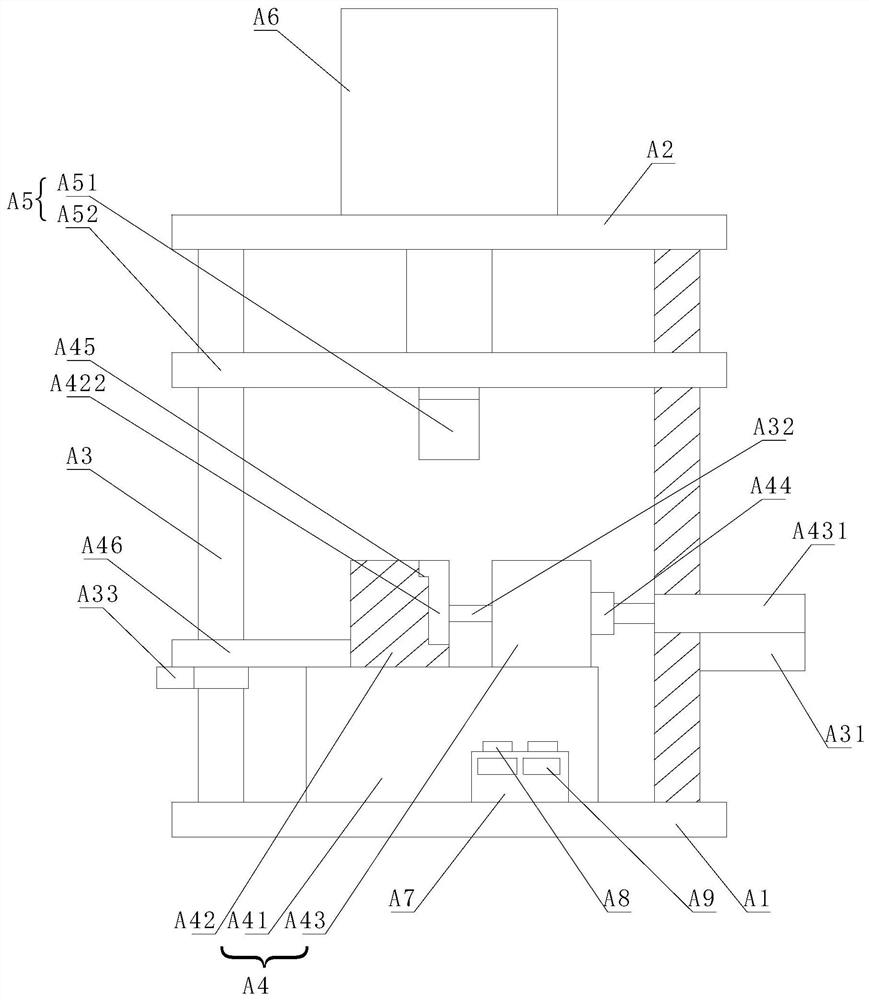

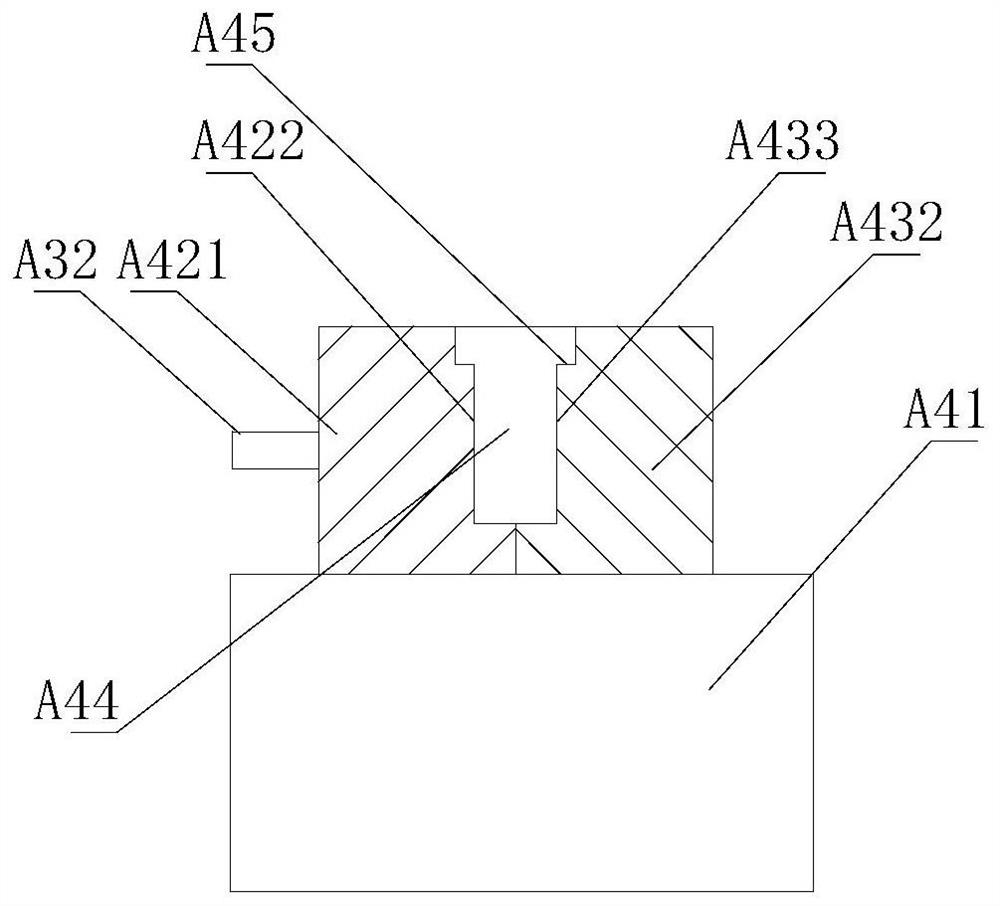

[0044] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, a water inlet pipe automatic production device includes a frame 1 and a conveyor belt 2 arranged on the frame 1, and the frame 1 is sequentially provided with a crimping assembly A, a receiving Tightening machine 3, detection assembly, the crimping assembly is used to crimp the aluminum nut in the water inlet pipe joint, the tightening machine 3 is the prior art, this embodiment does not make a detailed description, and the specific tightening machine includes The body and the tightening chuck arranged on the body, the tightening chuck is used for tightening the connection between the water inlet pipe joint and the water inlet pipe body, and the detection component includes a first detection device for detecting the installation quality of the water inlet pipe joint Mechanism C, and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com