Oil cooler assembling machine and assembling method

A technology of oil coolers and assembly machines, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as lower product quality, low efficiency, and artificial lamination tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

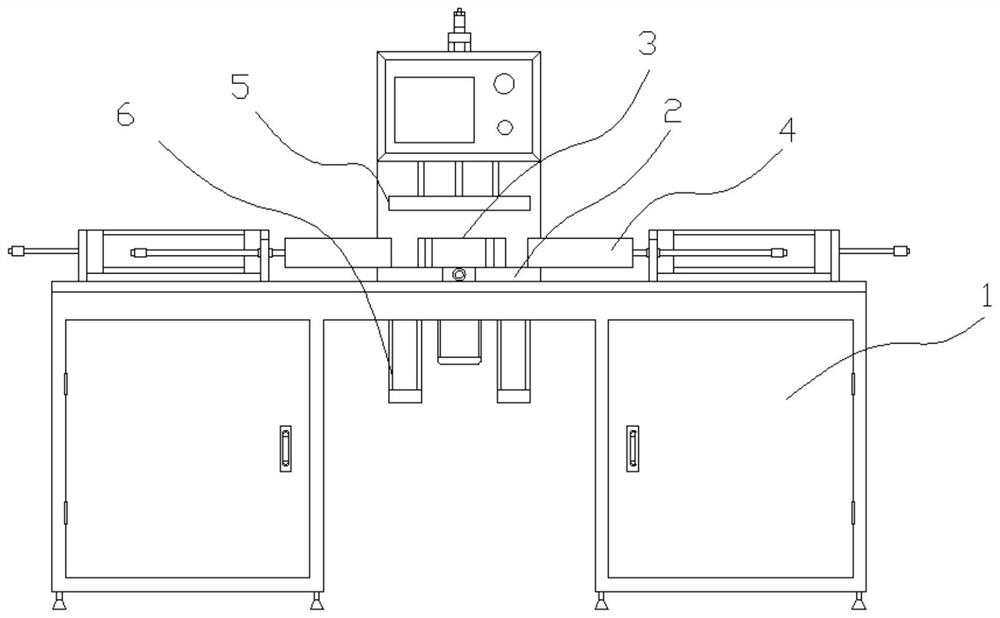

[0028] An oil cooler assembly machine, comprising:

[0029] Electric control cabinet 1, used to place electrical control components, including air switches, relays, controllers and connecting wires, etc.;

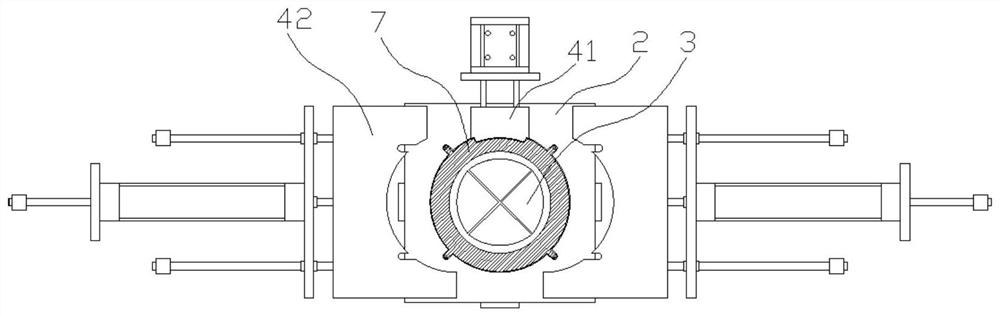

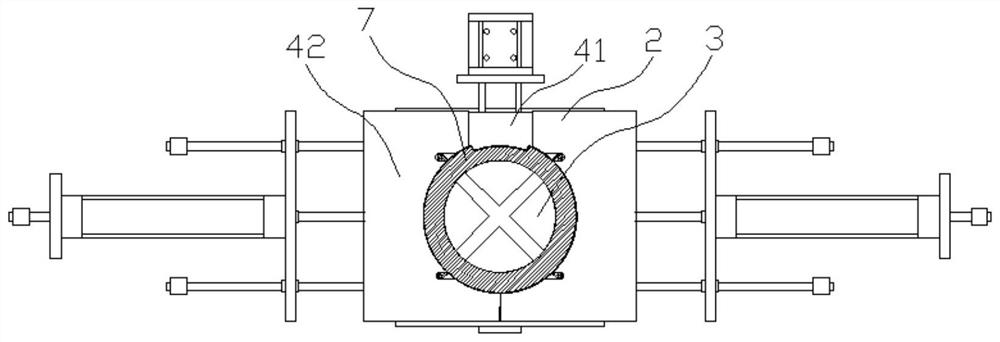

[0030] The lamination platform 2 is provided with a fixture placement groove 21 on the lamination platform, and the bottom of the fixture placement groove is provided with a through hole penetrating up and down;

[0031] Centering shaft 3, the centering shaft 3 is an expansion shaft, that is, the outer diameter of the centering shaft can be increased or reduced, the centering shaft can be an air expansion shaft or a tile type expansion shaft, and the centering shaft is vertically arranged on the lamination platform Above; the centering shaft has two positions: working position and waiting position. The working position is the position where the centering shaft locates the oil cooler, and the waiting position is the position where the centering shaft is away from the oil coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com