universal joint

A universal joint and axial technology, applied in the field of universal joints, can solve the problems of expensive structure of the separate sealing system, easy wear of the outer sealing lip, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

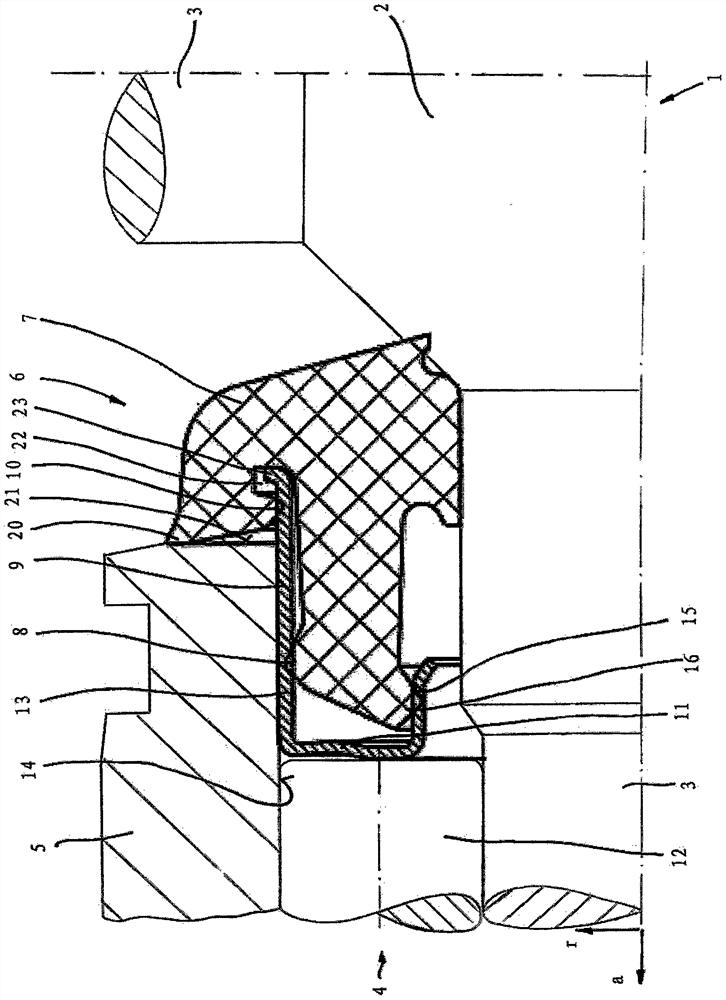

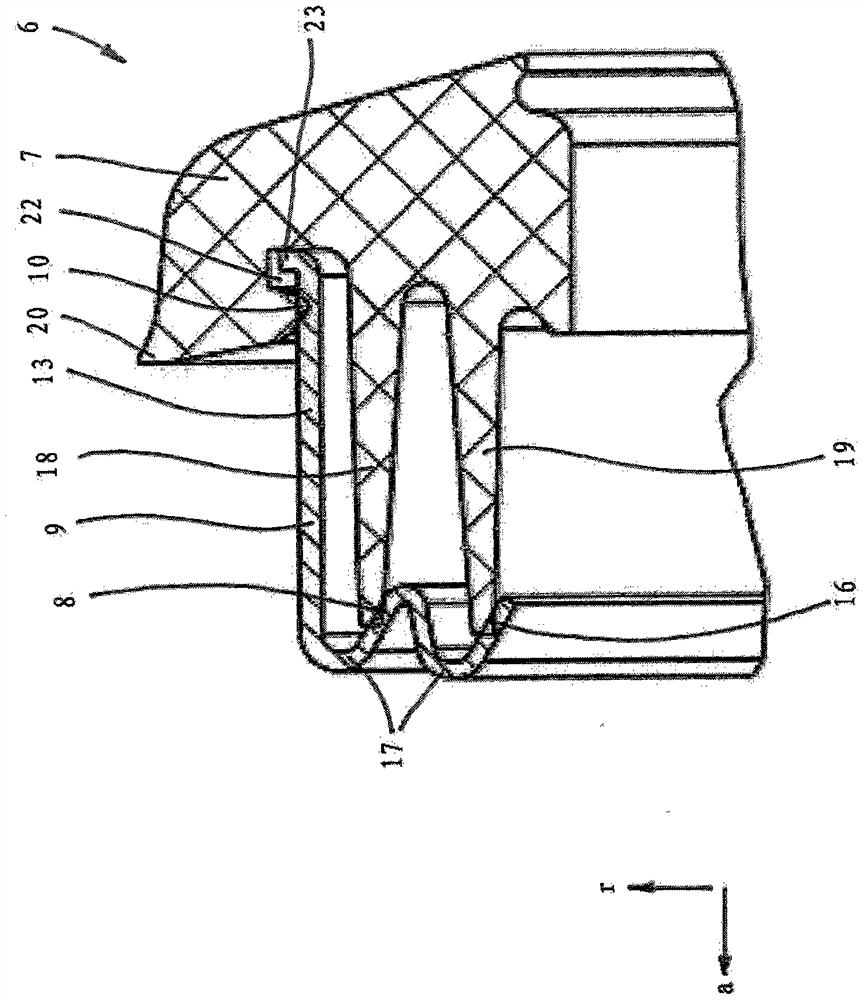

[0033] figure 1 is a simplified diagram of a portion of a universal joint 1 (depicting two of the four main journals 3 ) having a universal joint cross with the four main journals 3 supported in respective journal bearing arrangements 4 2. The journal bearing arrangement 4 is accommodated in a bushing 5 or the bushing 5 is a component part of the journal bearing arrangement 4 . In the present exemplary embodiment the journal bearing arrangement 4 is designed as a needle bearing arrangement.

[0034] For sealing the journal bearing arrangement 4 , for each bushing 5 a sealing arrangement 6 is located on the universal joint spider 2 .

[0035] The sealing device 6 has a sealing body 7 designed in one piece; this sealing body 7 is seated on the joint spider 2 in a static sealing manner. in accordance with figure 1 In the structural example of , the sealing body 7 has a radially outwardly directed first sealing lip 8 which is connected to the bushing 5 or - more precisely - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com