Spot welding system

A technology of spot welding and welding head, applied in general control system, control/adjustment system, welding equipment, etc., can solve problems such as low efficiency of spot welding, cumbersome operation, and threat to personal safety of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

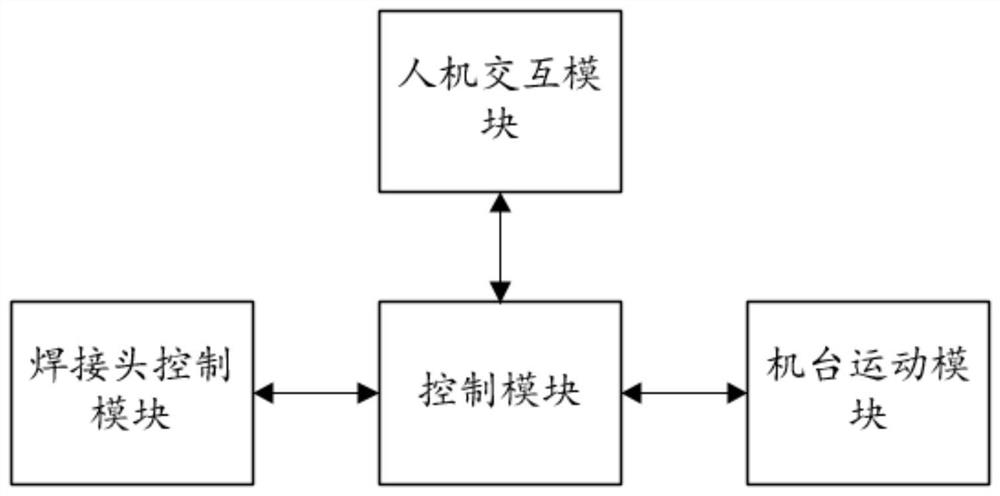

[0038] refer to figure 1 , a spot welding system, including a human-computer interaction module, a control module, a welding head control module and a machine motion module;

[0039] The human-computer interaction module is used to obtain motion parameters and send them to the control module;

[0040] The control module is used to control the motion module of the machine to move to the corresponding spot welding position according to the motion parameters, and send feedback information to the control module;

[0041] The control module is also used for sending execution information to the welding head control module according to the feedback information;

[0042] The welding head control module is used to control the welding head to perform spot welding according to the execution information.

[0043] During electric welding, place the battery and nickel sheet in the welding mold of the machine motion module, and set the motion parameters in the human-computer interaction mo...

Embodiment 2

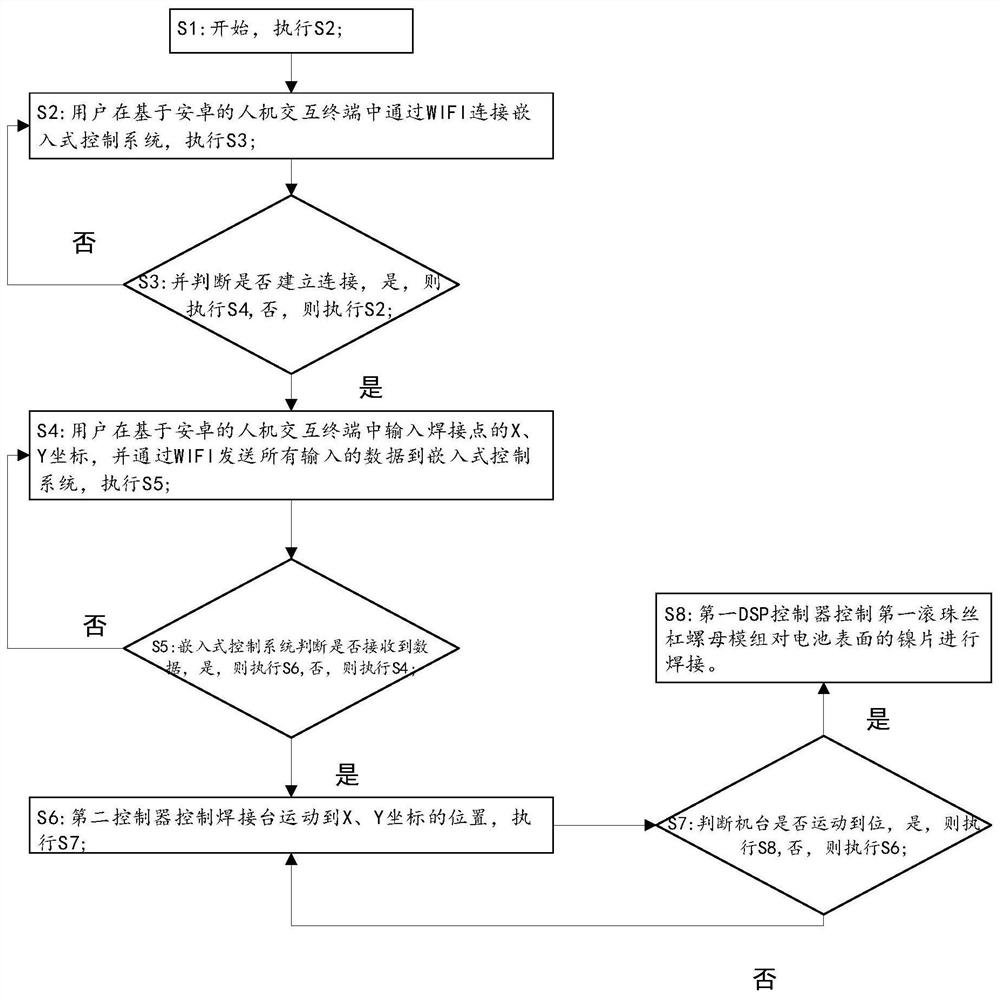

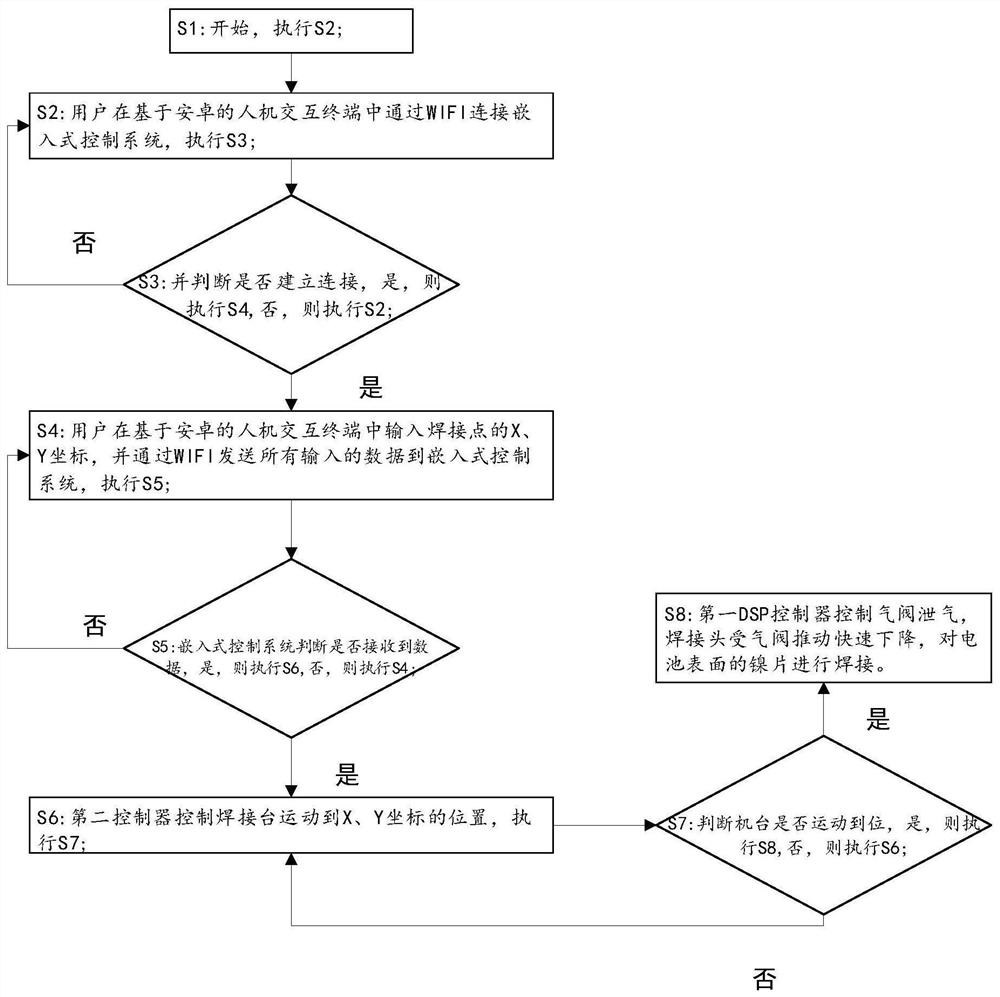

[0084] On the basis of embodiment 1, the spot welding joint control module is replaced by the first DSP controller and the pneumatic spot welding machine, and the first DSP controller is used to control the pneumatic spot welding machine to carry out spot welding, then the implementation principle of this embodiment is :

[0085] S1: start, execute S2;

[0086] S2: The user connects the embedded control system through WIFI in the Android-based human-computer interaction terminal, and executes S3;

[0087] S3: and judge whether to establish connection, if yes, then execute S4, if not, then execute S2;

[0088] S4: the user inputs the X, Y coordinates of the welding point in the human-computer interaction terminal based on Android, and sends all input data to the embedded control system through WIFI, and executes S5;

[0089] S5: The embedded control system judges whether the data is received, if yes, execute S6, otherwise, execute S4;

[0090] S6 The second controller contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com