Automatic mould release agent spraying equipment for shield segment mould

A technology for shielding segment and automatic spraying, which is applied in the direction of injection device and liquid injection device, can solve the problems of defects, low efficiency and reduced precision in the production process of shield segment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

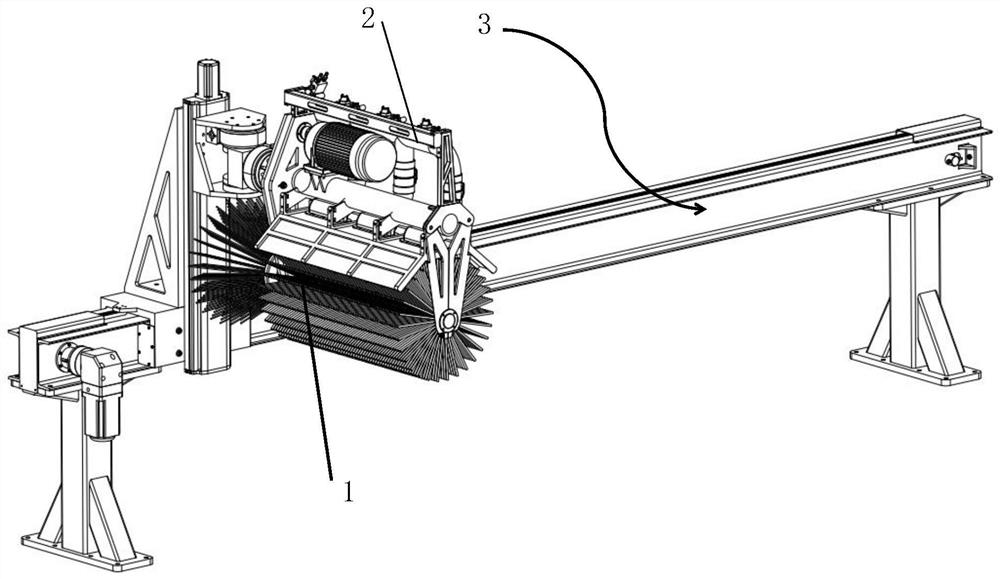

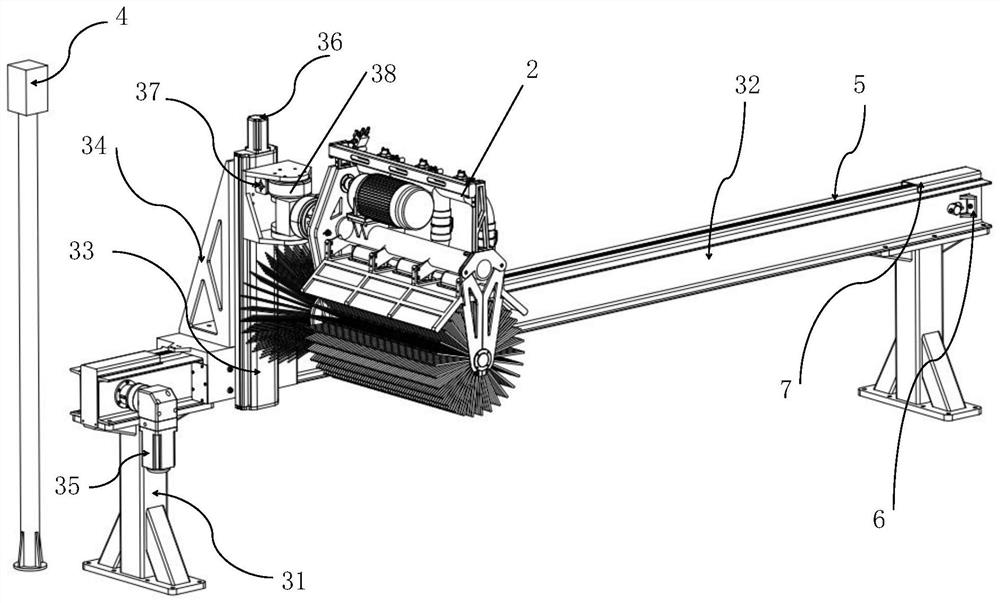

[0025] see Figure 1 to Figure 4 , this embodiment includes a control system, a spraying mechanism 2 and a moving mechanism 3, the spraying mechanism 2 is installed on the moving mechanism 2, the control system is respectively connected with the spraying mechanism 2 and the moving mechanism 3, and the shield tube is realized by controlling the spraying mechanism 2 Automatic spraying of release agent for sheet molds;

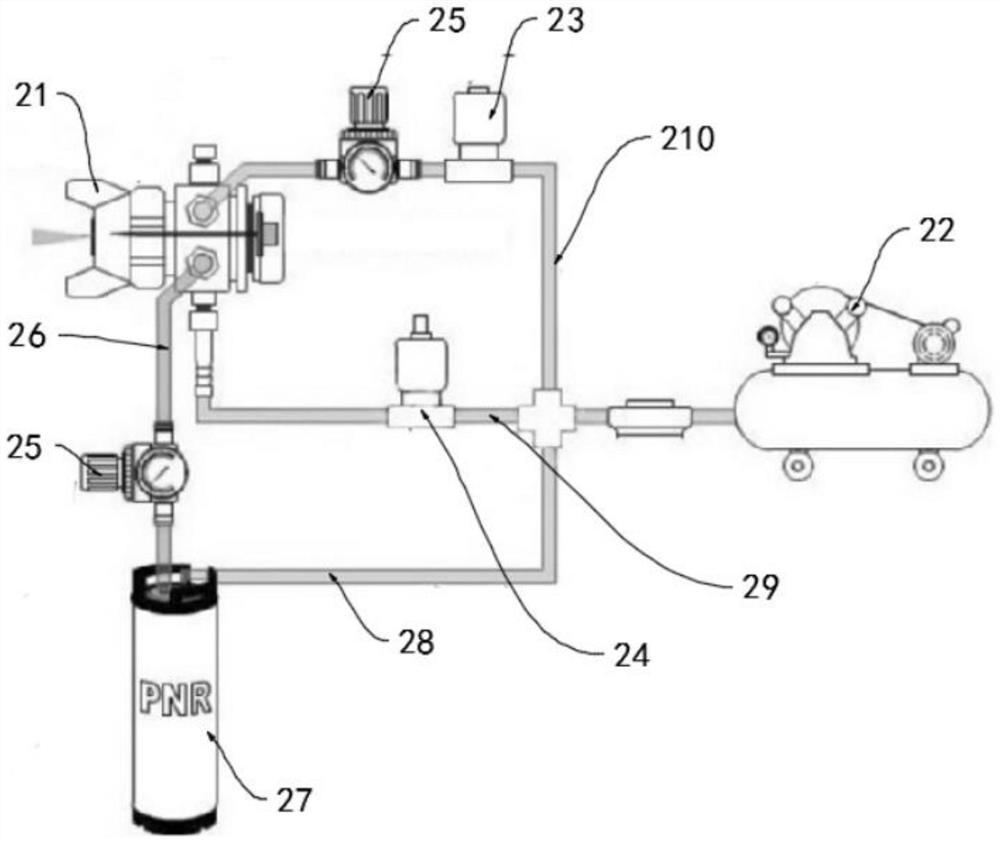

[0026] Described spraying mechanism 2 such as figure 2 Shown comprises spray nozzle 21, feed pipe 26, air compressor 22 and release agent raw material bucket 27, is provided with a plurality of interfaces on the spray nozzle 21, and air compressor 22 is respectively connected with some intake pipes such as the first intake pipe 28, the second Air intake pipe 29 links to each other with the 3rd air intake pipe 210, and release agent raw material barrel 27 connects first air intake pipe 28, and the first interface of shower nozzle 21 is communicated with release ...

Embodiment 2

[0037] see Figure 1 to Figure 4, this embodiment includes a control system, a spraying mechanism 2 and a moving mechanism 3, the spraying mechanism 2 is installed on the moving mechanism 2, the control system is respectively connected with the spraying mechanism 2 and the moving mechanism 3, and the shield tube is realized by controlling the spraying mechanism 2 Automatic spraying of release agent for sheet molds;

[0038] Described spraying mechanism 2 such as figure 2 Shown comprises shower head 21, feed pipe 26, air compressor 22 and release agent raw material barrel 27, is provided with a plurality of interfaces on shower head 21, and air compressor 22 is respectively connected with the first air inlet pipe 28, the second air inlet pipe 29 and The third air intake pipe 210 is connected, the release agent raw material barrel 27 is connected with the first air intake pipe 28, the first interface of the nozzle 21 is communicated with the release agent raw material barrel 2...

Embodiment 3

[0046] see Figure 1 to Figure 4 , this embodiment includes a control system, a spraying mechanism 2 and a moving mechanism 3, the spraying mechanism 2 is installed on the moving mechanism 2, the control system is respectively connected with the spraying mechanism 2 and the moving mechanism 3, and the shield tube is realized by controlling the spraying mechanism 2 Automatic spraying of release agent for sheet molds;

[0047] Described spraying mechanism 2 such as figure 2 Shown comprises shower head 21, feed pipe 26, air compressor 22 and release agent raw material barrel 27, is provided with a plurality of interfaces on shower head 21, and air compressor 22 is respectively connected with the first air inlet pipe 28, the second air inlet pipe 29 and The third air intake pipe 210 is connected, the release agent raw material barrel 27 is connected with the first air intake pipe 28, the first interface of the nozzle 21 is communicated with the release agent raw material barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com