Passive take-off and landing type high-speed mobile workbench of hydraulic machine

A high-speed moving, hydraulic press technology, used in presses, manufacturing tools, etc., to achieve high work efficiency, simplify systems, and reduce failure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

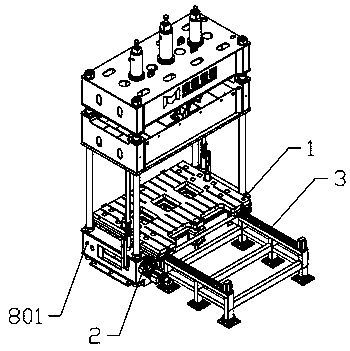

[0025] see figure 1 , a passive take-off and landing high-speed mobile workbench of a hydraulic press in the present invention mainly includes a mobile platform 1, a driving device 2, a line rail device 3, and the like.

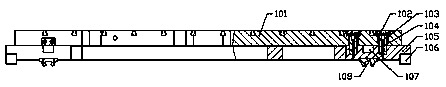

[0026] see figure 2 , the mobile platform 1 includes a main platform 101, an end cover 102, a guide sleeve 103, a cylindrical guide pin 104, a drag side plate 105, a rack 106, a spring lifting device 107, a line rail slider 108 and the like.

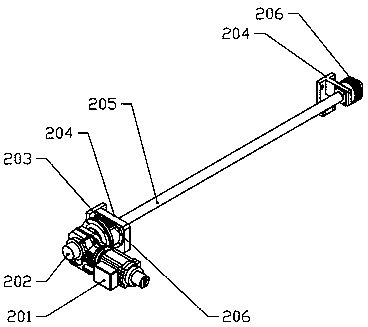

[0027] see figure 1 , image 3 , the driving device 2 includes a servo motor 201, a reducer 202, a flange 203, a bearing seat 204, a transmission shaft 205, a gear 206 and the like. The output shaft of the servo motor 201 of the driving device 2 is coaxially connected with the input shaft of the reducer 202 and transmitted through the key; the output shaft of the reducer 202 is connected with the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com