Disposable laser metal thermal therapy target head

A metal heat, disposable technology, applied in medical science, surgery, parts of surgical instruments, etc., can solve the problem of small laser target area and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

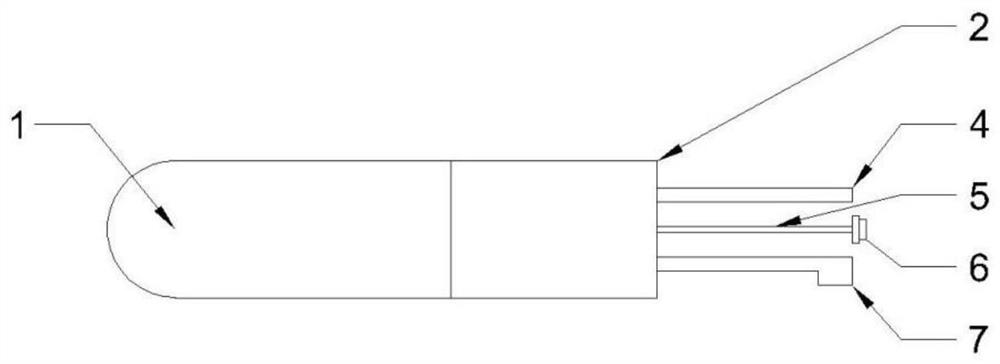

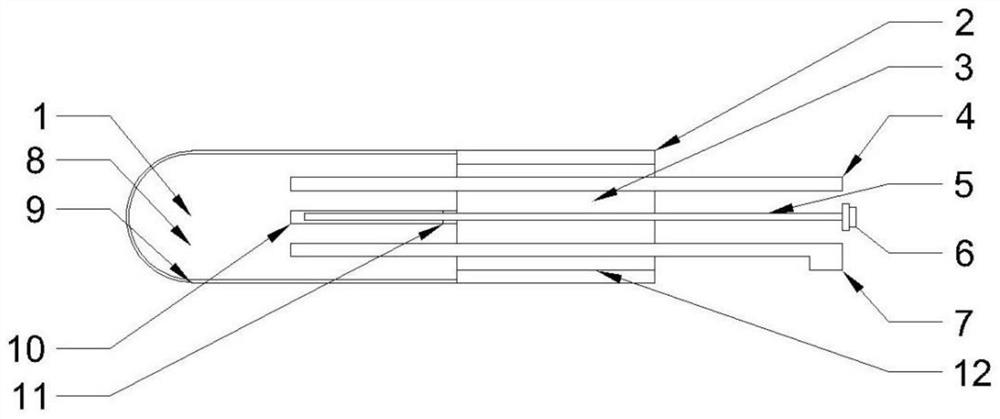

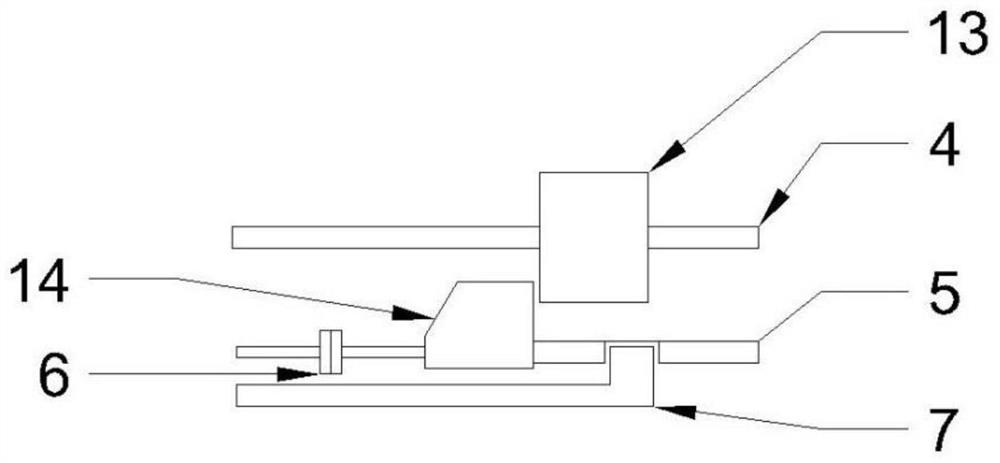

[0067] Such as Figure 1-3 As shown, a disposable laser metal hyperthermia target head, target head main body 1, extended plastic tube 2, plastic tube vacuum insulation layer 3, thermocouple 4, optical fiber 5, optical fiber connector 6, linear self-controlled temperature thermosensitive Material 7, aluminum-titanium alloy 8, pure silver coating 9, optical fiber hollow channel 10, optical fiber fixing glue 11, thermal insulation material 12, temperature sensor 13 and laser transmitter 14; the front end of the target head body 1 is a cylinder with a cone head , made of aluminum-titanium alloy 8, the outer wall of the front end of the target head main body 1 is coated with pure silver coating 9; the rear end of the target head main body 1 is an extended plastic tube 2, and the inside of the cross-sectional circumference of the extended plastic tube 2 is provided with a plastic tube for vacuum insulation Layer 3. The plastic tube vacuum insulation layer 3 contains thermocouples ...

Embodiment 2

[0082] Disposable laser metal hyperthermia target head such as Figure 1-3 As shown, see the description of embodiment 1 for details. Among them, the melting and casting method of the main body of the target head: under the protection of nitrogen gas, 900g aluminum powder, 40g titanium powder, 50g copper powder, 10g iron powder and 30g pore-forming agent polymethyl methacrylate powder are stirred and fully mixed, and cold rolled forming. Sinter at 400°C for 2h to remove the pore-forming agent, then sinter in vacuum at 1500°C for 4h, and then cool with the furnace until it is fully cooled and formed, then stop feeding nitrogen.

[0083] Figure 9 It is a schematic diagram of the temperature field change of the isolated pig liver caused by using the laser target manufactured in Example 2 when the laser power is 1W. Figure 9 Among them, the rate of change of the temperature field obtained is small, and the peak temperature is low. and Figure 7 The comparison of the tempera...

Embodiment 3

[0096] Disposable laser metal hyperthermia target head such as Figure 1-3 As shown, see the description of embodiment 1 for details. Among them, the melting and casting method of the main body of the target head: under the protection of nitrogen gas, 900g aluminum powder, 50g titanium powder, 40g copper powder, 10g iron powder and 30g pore-forming agent polymethyl methacrylate powder are stirred and fully mixed, and cold rolled forming. Sinter at 400°C for 2h to remove the pore-forming agent, then sinter in vacuum at 1500°C for 4h, and then cool with the furnace until it is fully cooled and formed, then stop feeding nitrogen.

[0097] The manufacturing method of the linear self-control temperature thermosensitive material comprises the following steps:

[0098] (1) Pretreatment of medical grade graphite powder: soak and clean medical grade graphite powder with acetone to remove organic substances that may be adsorbed on the surface of medical grade graphite powder, filter a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com