Steel member, steel sheet, and methods for producing same

A manufacturing method and technology of steel components, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

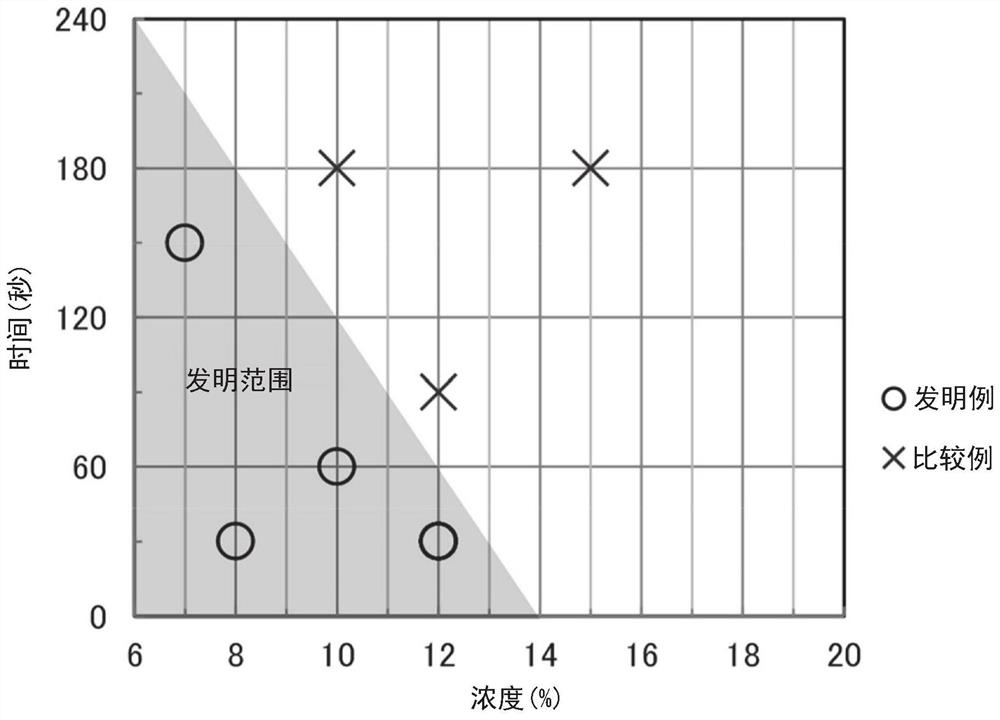

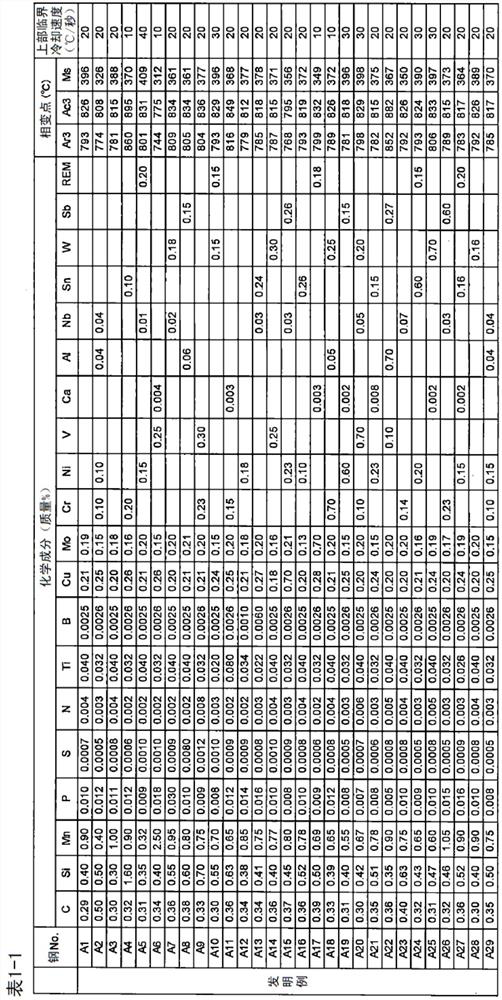

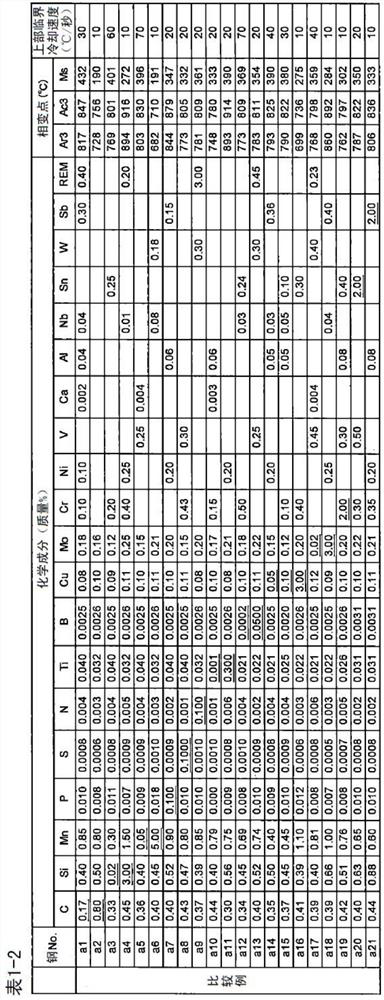

[0179] The slabs listed in Tables 1-1 to 1-2 were hot-rolled to obtain hot-rolled steel sheets with a thickness of 3.0 mm. In the hot rolling process, the slab heating temperature is set to 1250°C, the parameter S1 from rough rolling to finish rolling is set to 22657, the finish rolling end temperature is set to 930°C, and the average cooling rate is 20°C. °C / sec cooling to coiling, coiling at 550 °C.

[0180] The parameter S1 is controlled to 22657 within the range of 1 to 60 seconds from the end of rough rolling to the start of finish rolling, and the average temperature of the rough profile from the end of rough rolling to the start of finish rolling of 950 to 1150°C. Thereafter, the hot-rolled steel sheet was descaled for 30 seconds with hydrochloric acid having a concentration of 12% and a temperature of 90°C. Thereafter, cold rolling was performed by a cold rolling mill to obtain a cold-rolled steel sheet having a thickness of 1.4 mm.

[0181] The above-mentioned cold-...

Embodiment 2

[0199] The slabs listed in Tables 1-1 to 1-2 were hot-rolled to obtain hot-rolled steel sheets with a thickness of 3.0 mm. In the hot rolling process, the slab heating temperature is set to 1250°C, the parameter S1 from the end of rough rolling to the start of finish rolling is set to 22657, the finishing temperature is set to 930°C, and the temperature is set at 20°C / Second cooling to coiling, coiling at 550°C. The parameter S1 is controlled to 22657 within the range of 1 to 60 seconds from the end of rough rolling to the start of finish rolling, and the average temperature of the rough profile from the end of rough rolling to the start of finish rolling of 950 to 1150°C. Thereafter, the hot-rolled steel sheet was descaled for 30 seconds with hydrochloric acid having a concentration of 12% and a temperature of 90°C. Thereafter, cold rolling was performed by a cold rolling testing machine to obtain a cold-rolled steel sheet having a thickness of 1.4 mm.

[0200] With respec...

Embodiment 3

[0205] The hot rolling shown in Tables 4-1 and 4-2 was carried out on slabs having steel components of steel No. A28 and A29 among the steel types shown in Table 1-1 (a part was heated using a profile heater. ), pickling (hydrochloric acid or sulfuric acid), and manufactured hot-rolled steel sheets (thickness 2.8mm). The evaluation results of the structure of the obtained steel sheets are shown in Tables 4-1 and 4-2. It should be noted that t1 (seconds) in Tables 4-1 and 4-2 is the time from the end of rough rolling to the start of finish rolling, and T1 (°C) is the temperature of the rough profile from the end of rough rolling to the start of finish rolling. The average temperature, S1, is a value obtained by (T1+273)×(logt1+20).

[0206] However, the unit of t1 in the formula of S1 is (hour).

[0207]

[0208]

[0209] Invention examples D1 to D22 satisfying the scope of the present invention showed good Cu surface enrichment degree and average crystal grain size, bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com