Device and method for movably heating cigarette paper tube

A cigarette paper and mobile technology, which is applied in the direction of chemical analysis by means of combustion, can solve the problems of not being able to simulate the temperature field of cigarettes well, it is difficult to maintain the normal shape of the cigarette tube burning, and the test temperature is inconsistent with the real combustion temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

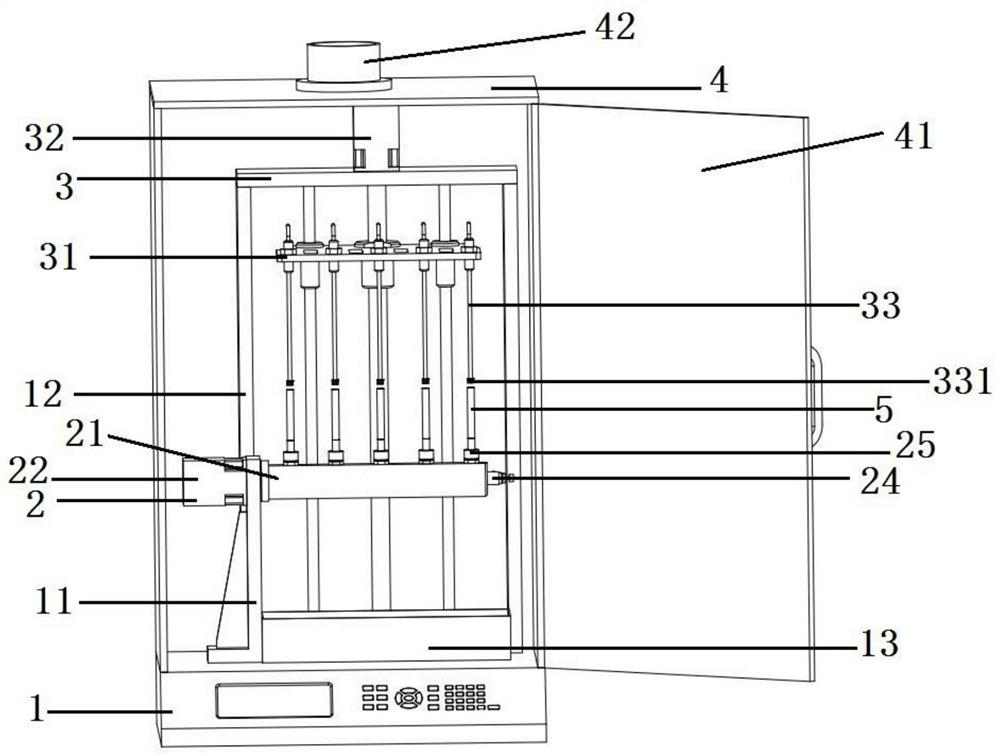

[0047] In this embodiment, the mobile heating cigarette paper tube device of the present invention is used to test the soot grayness of different cigarette sample cigarette paper tubes after burning, which specifically includes the following steps:

[0048] (1) The cigarette is fixed on the turning drum 21 through the cigarette holder 25, and the cigarette holder 25 fixes one end of the cigarette filter

[0049] (2) Control the steering drive motor 22 to drive the steering drum 21 to rotate, so that the cigarette holder 25 fixes one end of the cigarette facing away from the heating rod 33;

[0050] (3) Open the air blowing valve 24, and the air blower connected with the air blowing valve 24 blows the air in the environment into the ventilation duct 23, and then the tobacco in the cigarette is blown out by the cigarette holder 25, so that there is no air in the cigarette. Tobacco cigarette paper tubes;

[0051] (4) Control the steering drive motor 22 to drive the steering drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com