An integral solid rocket ramjet inlet outlet plug cover

A technology of ramjet and solid rocket, which is applied in the field of aerospace power, can solve the problems of the combustion impact of the afterburner, affect the attitude of the missile, and high manufacturing costs, and achieve the effect of simple use, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

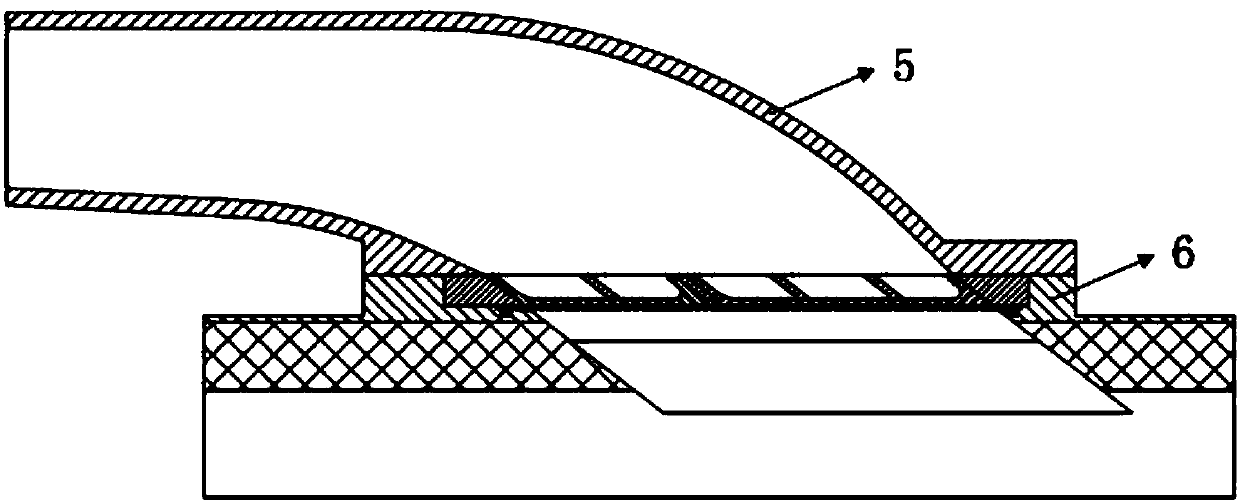

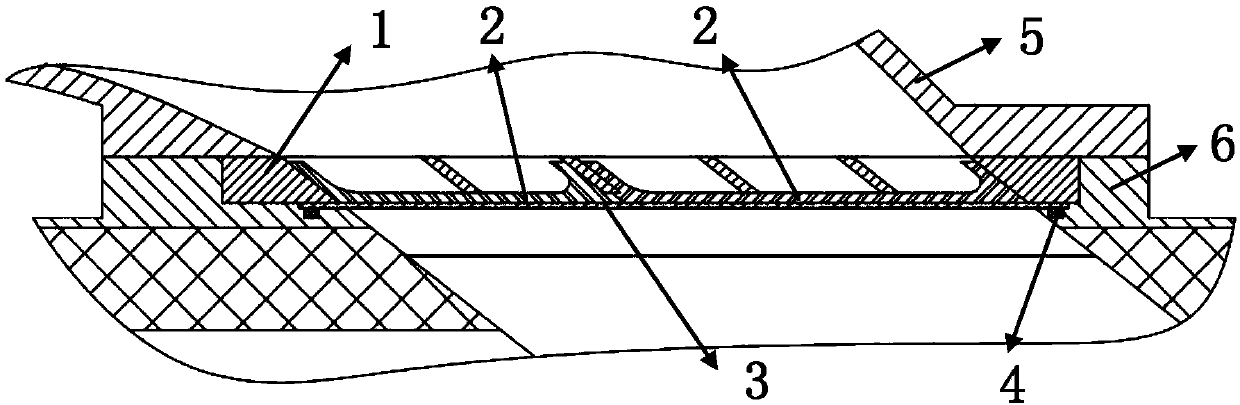

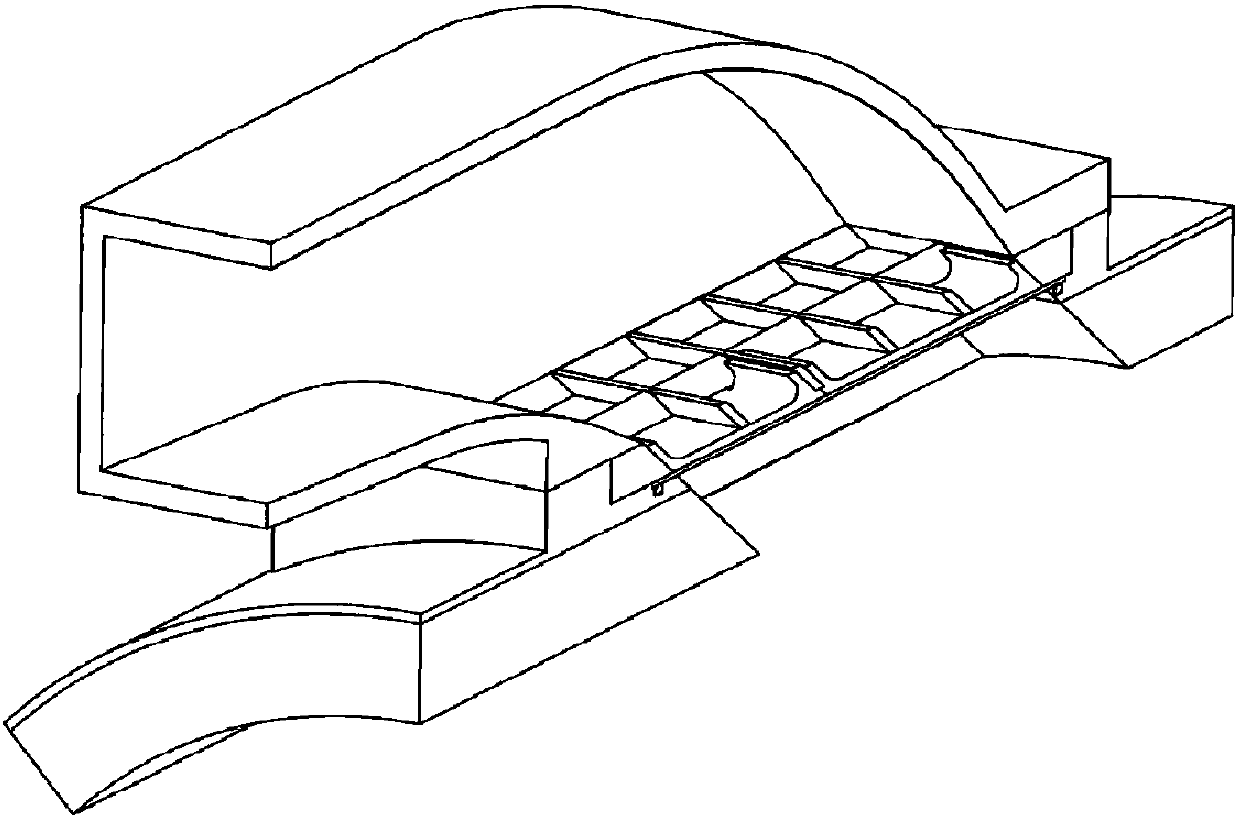

[0020] See figure 1 , 2 And 3, an integral solid rocket ramjet engine inlet outlet plugging cover, which is designed to be automatically blown off under ram air, including a support grid 1, a U-shaped pressure plate 2, a rubber gasket 3 and a sealing ring 4.

[0021] The support grid 1 is made of metal material, and is installed between the air inlet 5 and the afterburner housing 6, and is used for the high-pressure load of the gas transmitted by the U-shaped pressure bearing plate 2. The U-shaped pressure bearing plate 2 is made of light alloy or glass fiber reinforced plastic material, embedded in the support grid 1, used to support the rubber gasket 3, and transmits the high pressure load of the gas to the U-shaped pressure bearing plate 2; the rubber gasket 3 is made of rubber material , installed between the air inlet 5 and the support grid 1, used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com