Pressure probe for measuring fluid pulse dynamic pressure

A pulse and pressure technology, applied in the direction of fluid pressure measurement using piezoelectric devices, can solve the problems of strong interference signal strength, high frequency, and no high-speed flow medium to measure local pressure contact probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only for illustration and are not intended to limit the present invention.

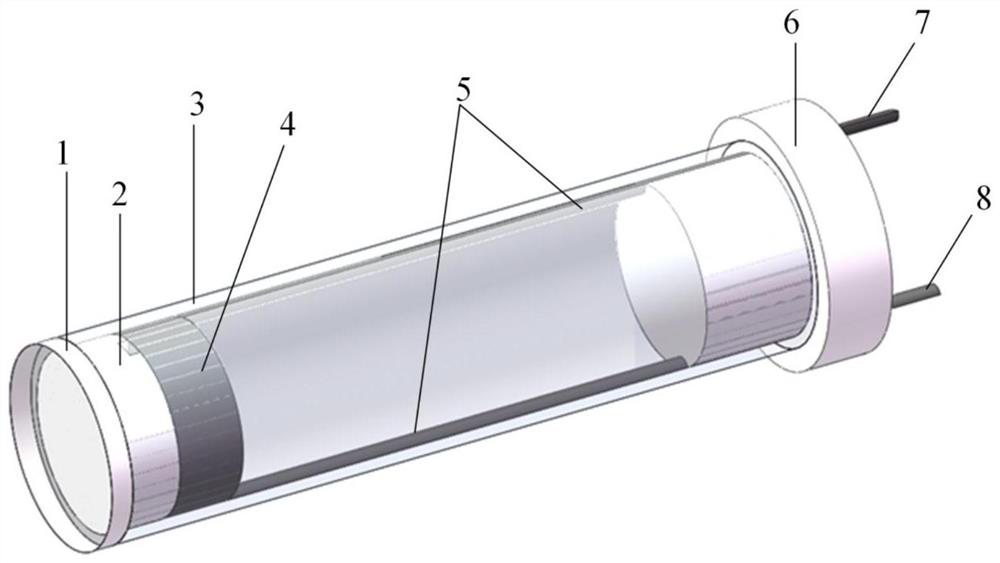

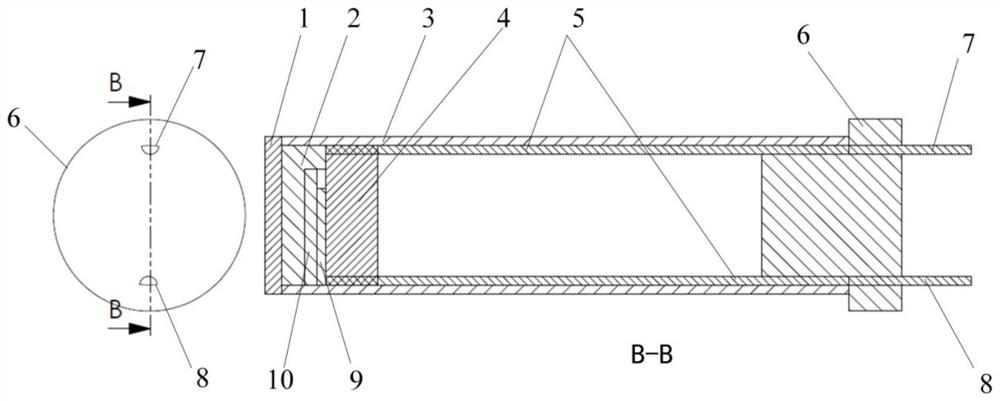

[0021] The present invention provides a pressure probe for measuring fluid pulse dynamic pressure, such as figure 1 with figure 2 as shown, figure 2 for figure 1 The sectional view, including: quartz glass sheet 1, piezoelectric sensor 2, glass tube 3, PTFE piston 4, terminal positive pole 5 and terminal negative pole 6; wherein,

[0022] The piezoelectric sensor 2 includes a piezoelectric ceramic 7 and a piezoelectric ceramic positive electrode 8 and a piezoelectric ceramic negative electrode 9 respectively located on the front and back sides of the piezoelectric ceramic 7;

[0023] The piezoelectric sensor 2 is located in the glass tube 3, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com