Two-stage compression sliding vane vacuum pump driven by rotary ring

A two-stage compression, sliding vane technology for use in rotary piston/oscillating piston pump components, rotary piston/oscillating piston pump combinations for elastic fluids, and components for pumping devices for elastic fluids It can solve problems such as unfavorableness, small change of shape line vector diameter, and increase of internal volume ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

[0044] like figure 1 As shown, it is a three-dimensional assembly diagram of a two-stage compression vane vacuum pump driven by a swivel, including: front end cover (1), swivel cover (2), swivel (3), sliding vane (4), Cylinder (5) and rear end cover (6).

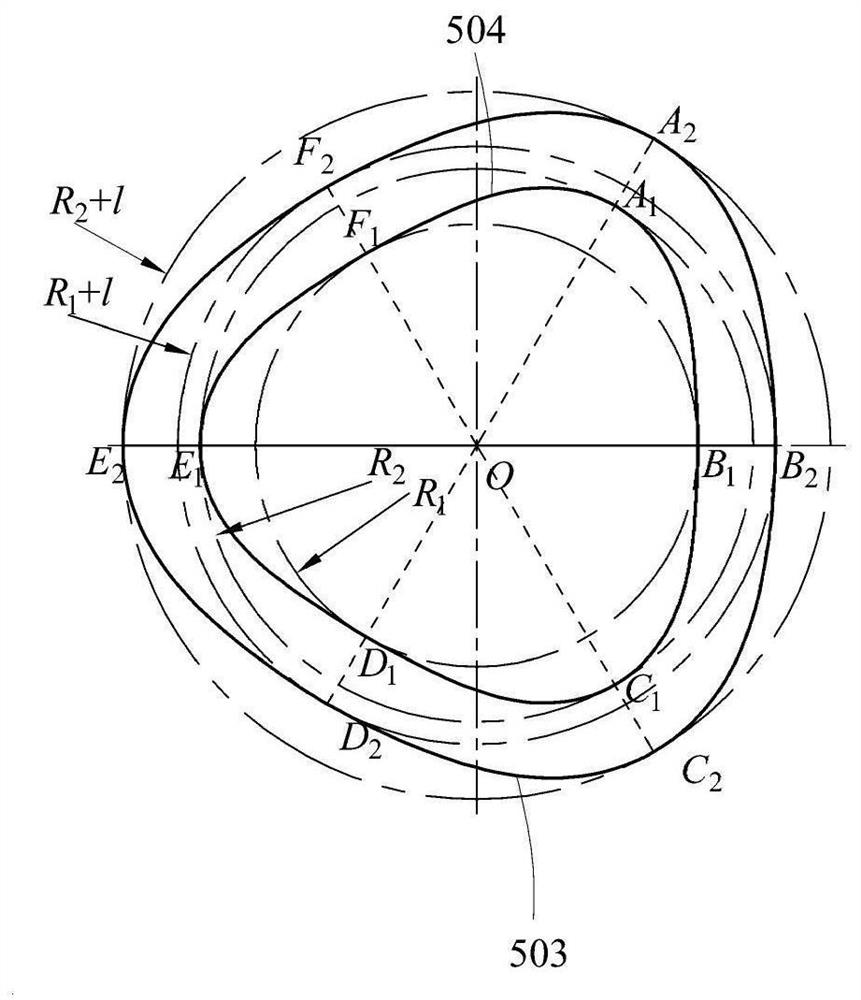

[0045] like figure 2 As shown, it is an inner chamber profile diagram of a two-stage compression vane vacuum pump driven by a swivel, and the contour profile diagram of the cylinder (5) is formed in the following way: the center of rotation of the cylinder (5) is the coordinate origin O Set up the polar coordinate system, the equation of the inner cylinder profile (504) is:

[0046]

[0047] The equation of the outer cylinder profile (503) is:

[0048]

[0049] Among them, ρ—the vector diameter of the cylinder profile, mm;

[0050] R 1 —The radius of the inscribed circle of the molded line inside the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com