Construction method for continuous tunneling of coal mine TBM and coal mine TBM

A construction method and technology for coal mines, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as low work efficiency in rock roadway excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: as Image 6 As shown, a coal mine TBM includes an explosion-proof shield body 101 and a slag removal system 103, both of which adopt an explosion-proof design to meet the safety requirements of coal mine excavation. The cross-section of the explosion-proof shield 101 can be circular or rectangular as required. The front end of the explosion-proof shield body 101 is provided with an excavation device 102, and the design of the excavation device can adopt the existing cutter head design. The combined use of the excavation device can realize the steering of the excavation device, making the excavation more flexible and realizing continuous excavation. The slag discharge system 103 corresponds to the slag discharge port of the excavation device 102, and the slag discharge system 103 can use a central belt conveyor and a tail belt conveyor for smooth slag discharge during the excavation process.

[0033] Further, the explosion-proof shield body 101 includes a...

Embodiment 3

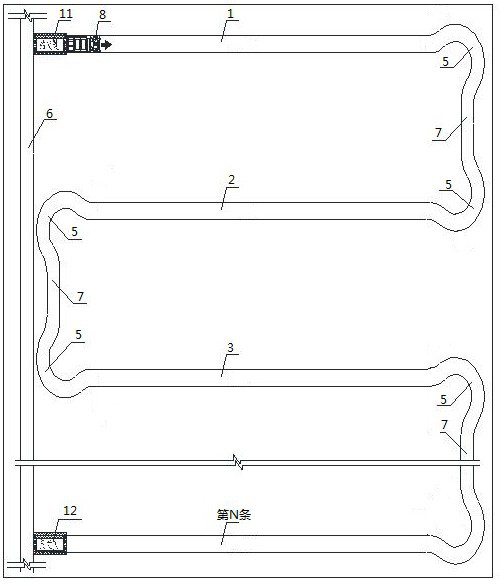

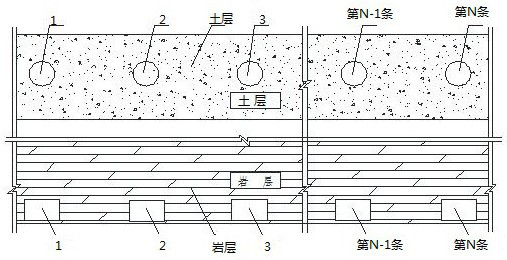

[0043] Embodiment 3, a construction method for continuous tunneling by TBM in a coal mine. In step S6, when N=1, the steps are as follows: B1: excavate two main transport roadways 6 longitudinally on both sides of the area to be excavated. The preset position of a main transport roadway 6 is used as a starting site 11 arranged laterally, and the preset position of another transport roadway 6 is used as a receiving site 12 arranged horizontally; The site is located at another level of the excavated rock lane;

[0044] B2: Hoist the coal mine TBM to the starting site 11, and then carry out continuous lateral excavation of the first rock roadway 1 along the preset route;

[0045] B3: When the coal mine TBM finishes excavating the first rock roadway, it just returns to the receiving station 12, and then lifts the coal mine TBM out of the roadway along the main transport roadway 6 to complete the entire excavation work.

[0046] In the step S6, N (N≥2) rock roadways are arranged i...

Embodiment 4

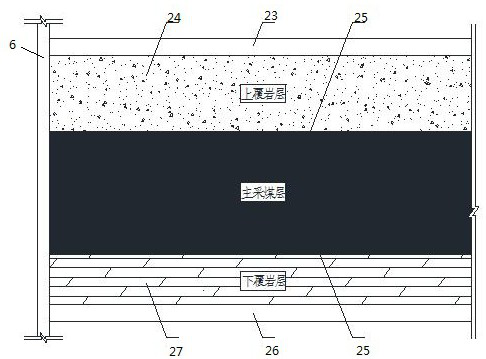

[0049] Embodiment 4: as Figure 3-5 As shown, taking the gas drainage roadway digging in the working face of the main mining coal seam of the coal mine as an example, the main mining coal seam 25 is a high-gas coal seam. 6 excavation. That is, gas drainage must be performed on the mining face before mining, and before the working face of the main mining seam is excavated along the trench 28, the coal mine TBM8 is used in the overlying strata 24 of the main coal mining seam 25, along the trench with the working face of the main coal mining seam. 28 into a certain angle and azimuth, and excavate the high-level gas drainage lane or measure lane 23, or adopt a coal mine TBM8 in the overburden layer 27 under the main coal mining seam 25, and form a certain angle and azimuth with the main coal mining seam working face along the groove 28, Excavate the low-level gas drainage roadway 26, and use the coal mine TBM8 to carry out the small turning radius, reciprocating, continuous and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com