Vortex spinning anti-pilling knitted fabric

An anti-pilling technology for knitted fabrics, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of poor anti-static performance, easy static pilling, and affecting the wearability of fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

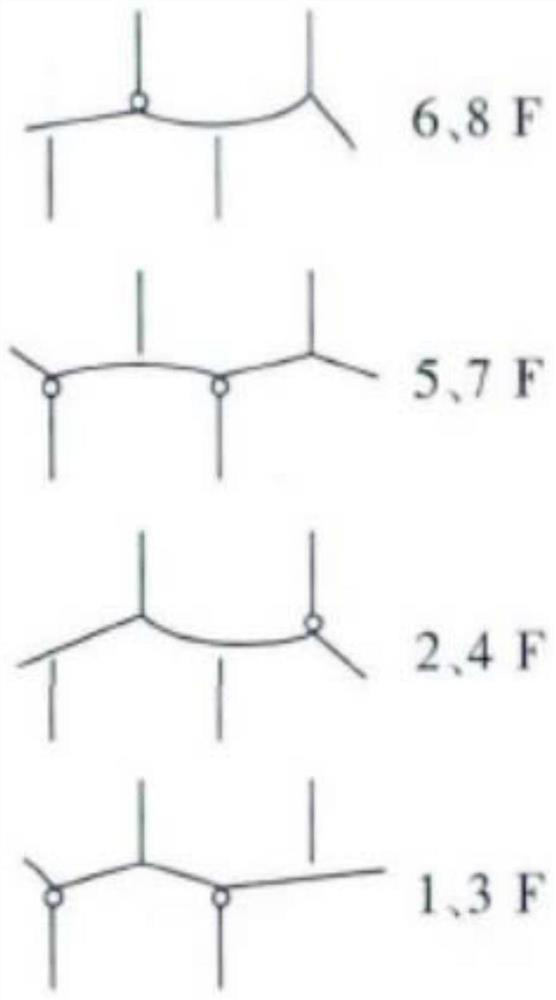

[0016] The invention discloses a vortex spinning anti-pilling knitted fabric, which comprises a fabric body. The body of the fabric has a rib-knit construction. The odd-numbered and even-numbered paths of the fabric body are all penetrated and knitted by antistatic core-spun yarns. Specifically, it can be used as figure 1 The knitting diagram shown is for knitting. The dial knitting needles are arranged in the order of AB, and the two sections are a cycle. The cylinder knitting needles are arranged in the order of butt height AB, and two needles are in a cycle. 8F is a pattern cycle. Knitted fabrics are formed through the mutual cooperation of loop-forming cams, tuck cams and floating cams. The antistatic corespun yarn of the present invention includes a core yarn and a wrapping fiber. The wrapping fibers are organic cotton fibers. The wrapping fibers are helically wrapped around the core yarn. The core yarn includes a core yarn layer and a skin layer. The core yarn lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com