A barrel solidified grease discharge device

A technology of unloading device and grease, which is applied in the direction of loading/unloading, packaging, transportation and packaging, etc. It can solve the problems of material spillage and odor control difficulties, low unloading efficiency, and adhesion, etc., to reduce labor intensity, Effect of preventing emission into the environment and improving discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and examples.

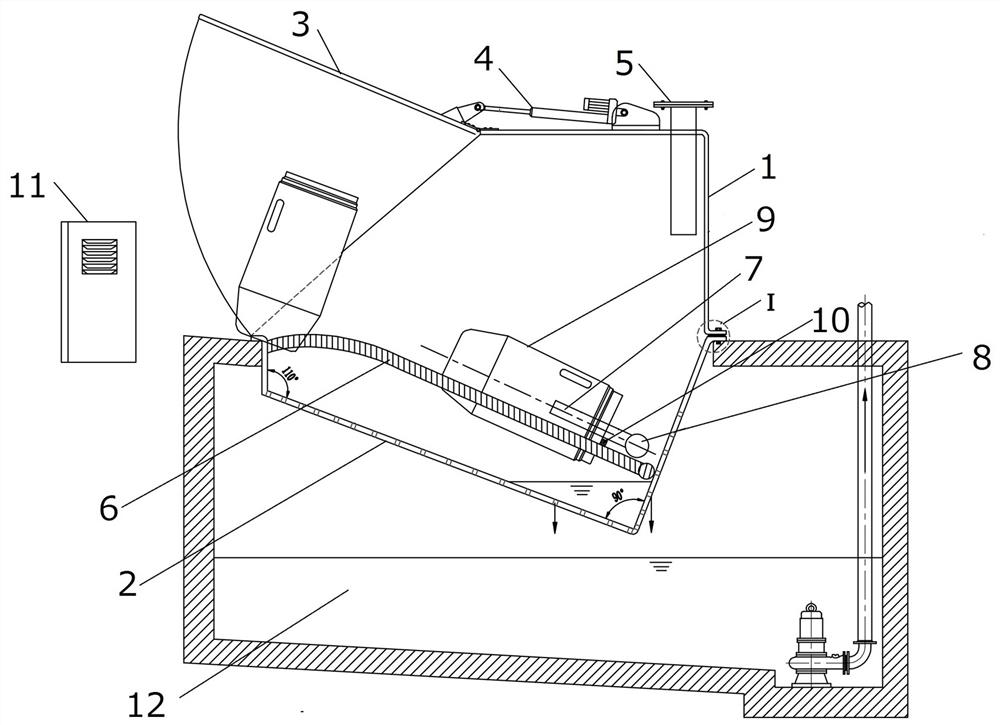

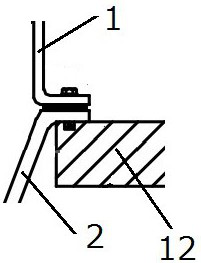

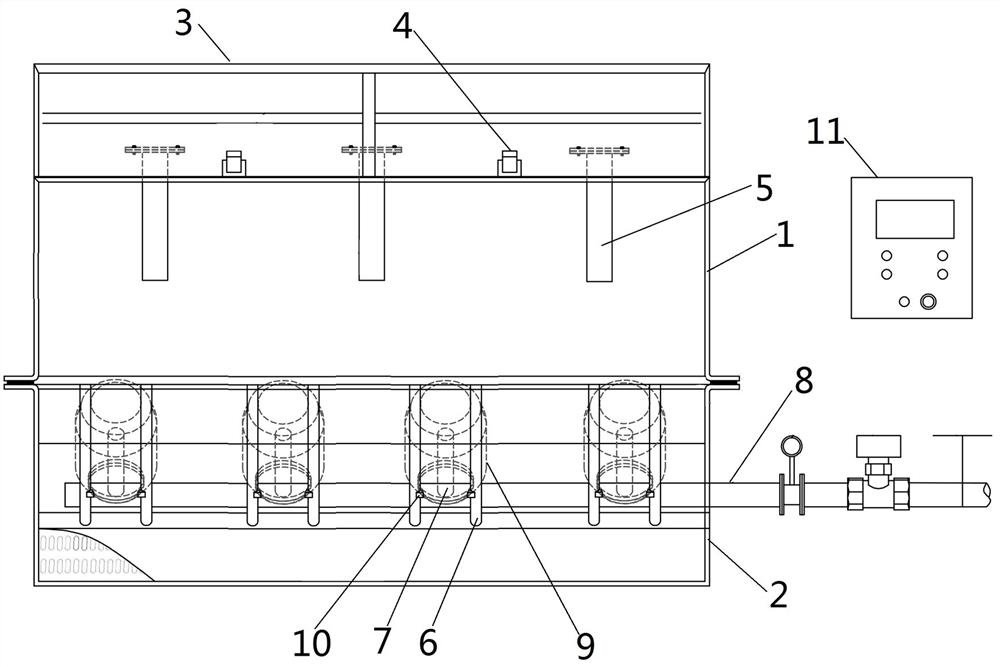

[0022] Such as Figure 1 ~ 3 As shown, a bucket is solidified oil discharge device, including a trapezoidal hovera 1 and a hopper 2. The components of the discharge device have the possibility of contact with the material, in order to ensure that the components are not corroded, each component uses 304 stainless steel.

[0023] The bottom of the hood 1 is completely open, and a unloading port is provided on one side of the hood 1, which is provided with a cover plate 3, and the remaining sides are sealed. The cover 3 and the hood 1 are connected by hinges or hinges. The top of the hood 1 is fixedly provided with the electric push rod 4, and the telescopic end of the electric push rod 4 is connected to the cover 3. The opening and closing of the cover plate 3 is controlled by the electric push rod 4, the electric push rod 4 is retracted inward, the cover plate 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com