Marine composite superstructure bulkhead and preparation method thereof

A composite material and superstructure technology, applied in hull bulkheads, ship construction, chemical instruments and methods, etc., can solve the problems of heavy building weight, insufficient bulletproof plate protection and electromagnetic stealth performance, fatigue fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

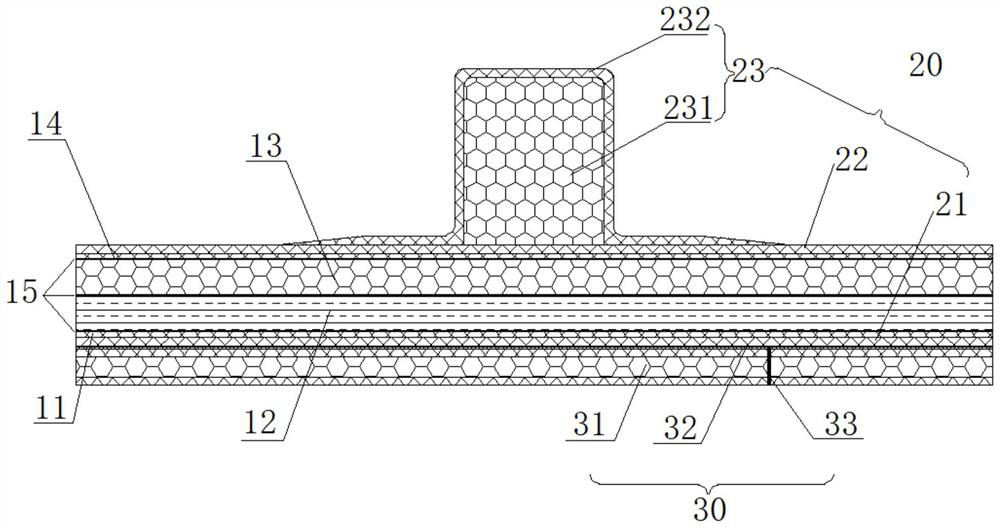

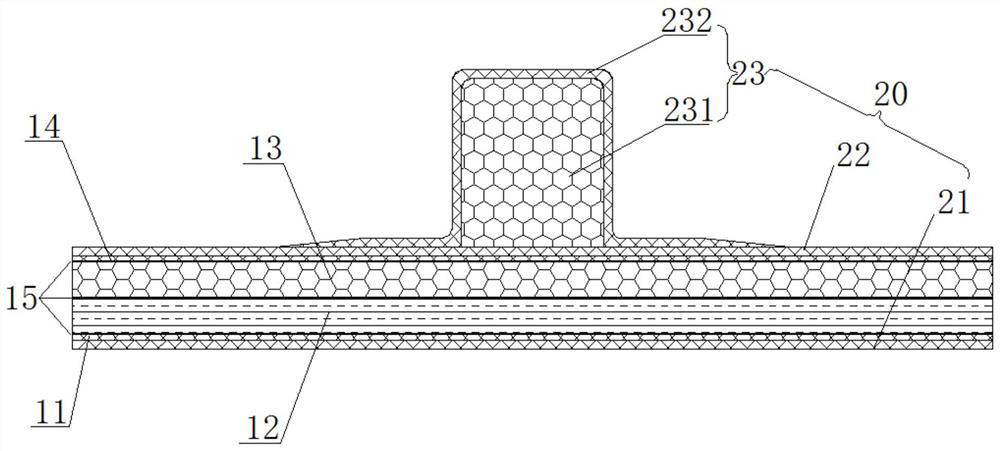

[0049] Such as figure 1 As shown, a marine composite material superstructure bulkhead provided by the present invention includes a protective sandwich structure 10 , a reinforcement structure 20 and a radar stealth structure 30 .

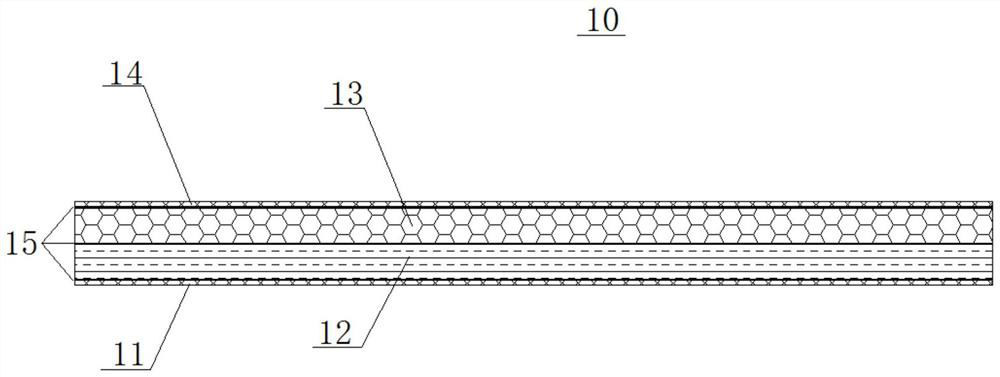

[0050] Such as figure 2 As shown, the protective sandwich structure 10 includes a lower skin 11, an ultra-high molecular weight polyethylene armor plate 12, a PVC foam layer 13 and an upper skin 14 arranged sequentially from bottom to top, and the layers are bonded by adhesive into one.

[0051] Such as Figure 3-4 As shown, the reinforcement structure 20 includes a bottom FRP layer 21 , a surface FRP layer 22 , PVC foam reinforcement ribs 231 and a glass fiber reinforced skin 232 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com