Metal dust collecting and self-cleaning device for machining

A metal dust and machining technology, applied in the field of machining, can solve the problems of affecting the air circulation of the device, cumbersome, network port blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

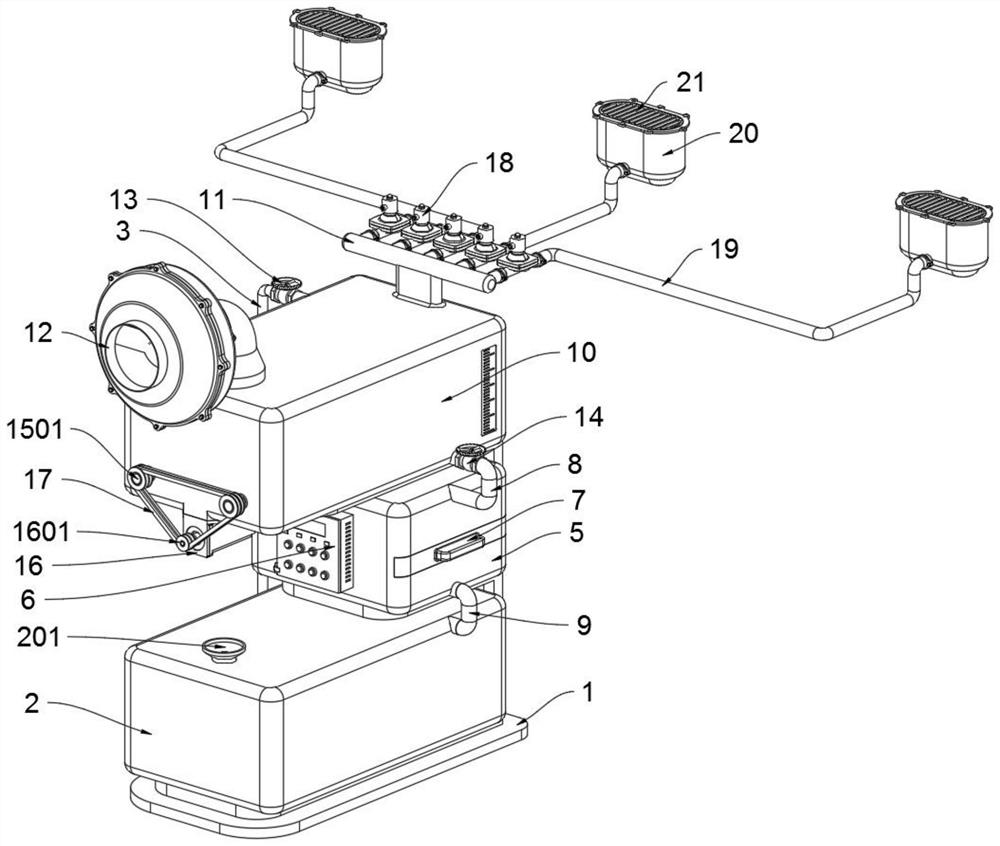

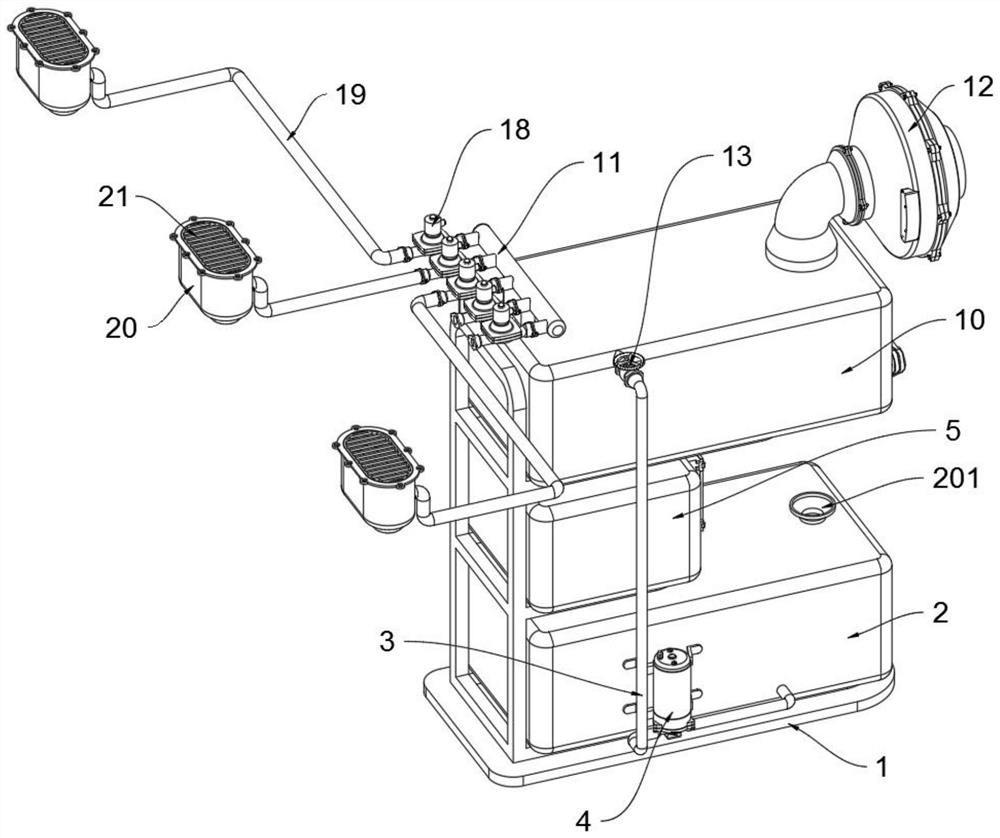

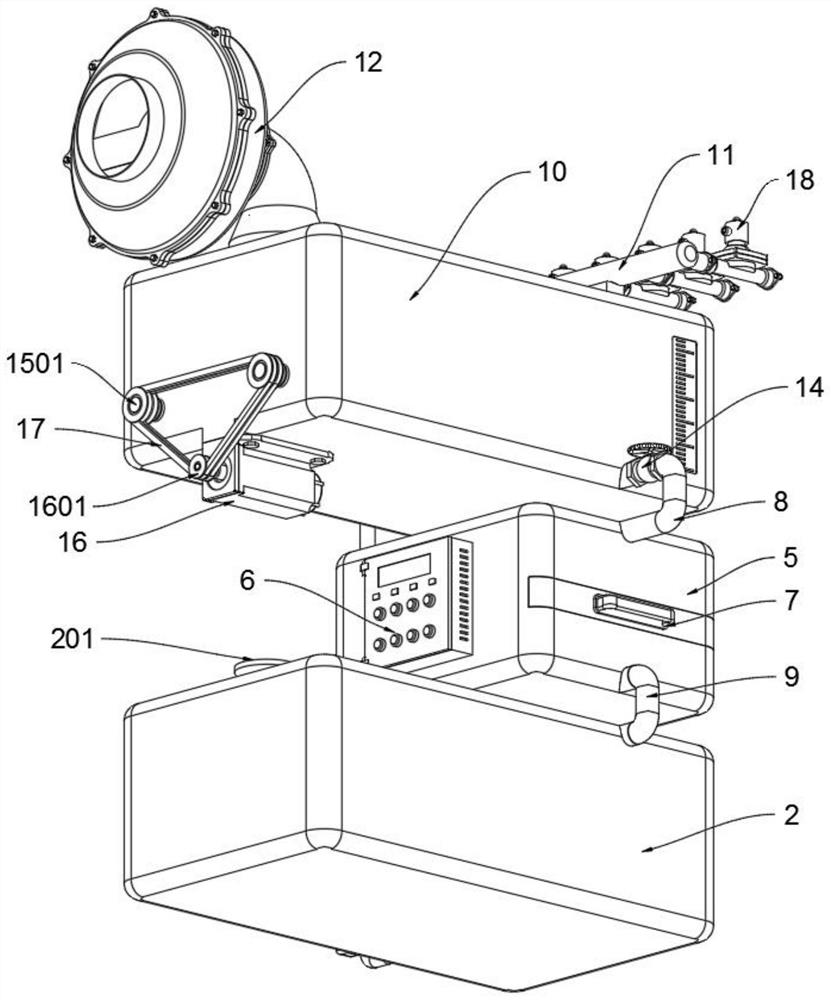

[0035] as attached figure 1 to attach Figure 11 Shown:

[0036]The present invention provides a metal dust collection self-cleaning device for mechanical processing, comprising a support frame 1, a return pipe 3, a filter box 5, a control electric box 6, a water inlet pipe 8, a drain pipe 9, a purification box 10, and a spiral stirring shaft 15. Drive motor 16, air extraction pipe 19, collection leakage shell 20 and filter pipe fitting 21; the support frame 1 is divided into three layers, and the water storage tank 2 is installed on the bottom of the support frame 1, and there is a filling place on the top of the water storage tank 2 Nozzle 201; the bottom of the return pipe 3 is connected to the outside of the water storage tank 2, and the top of the return pipe 3 is connected to the water inlet valve 13; the filter box 5 is installed on the middle layer of the support frame 1, and the filter frame 7 is located inside the filter box 5; the control circuit The box 6 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com