Matching method of lithium ion batteries

A lithium-ion battery and grouping technology, which is applied in the field of lithium-ion batteries, can solve problems such as voltage, internal resistance, and capacity changes that are not considered, so as to reduce the occurrence of bad phenomena in the later stage, improve consistency, and battery utilization. Improve the effect of bin capacity difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

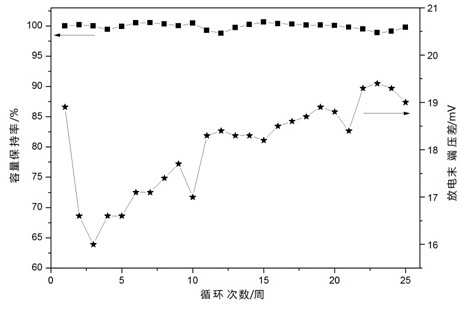

[0021] Take our company's 726385P / 5800mAh battery cells as an example through the series connection of three cells.

[0022] The first step: paste the QR code on the 726385P / 5800mAh type cell battery, and then paste the surface protective film on the surface of the cell;

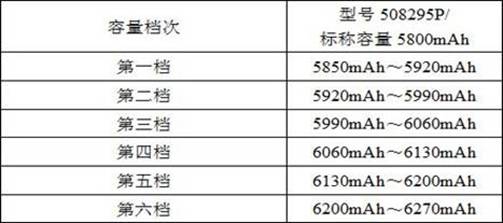

[0023] Step 2: Charge to full power with 0.5C current constant current and constant voltage, cut-off current 0.02C; then constant current discharge to cut-off voltage, and then charge the battery with constant current and constant voltage to 3.80V again to ensure the voltage of each battery Consistency, record the battery discharge capacity at the same time, remove the batteries with a capacity outside the range of 5850mAh~6270mAh, and then divide the remaining batteries according to the capacity difference of 70mAh, a total of six levels;

[0024] Step 3: Leave the cells in the second step in the cabinet for 5 hours, then test the voltage V1 and internal resistance R1 of the cells, and record them through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com