Planetary pin roller lead screw

A planetary roller, roller technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve the change of planetary roller screw transmission ratio, slip, differential planetary roller screw drive ratio instability and other problems, to achieve the effect of improving accuracy, stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with embodiment.

[0039] In order to prevent the rollers and nuts of the differential planetary roller screw from sliding and improve the precision of the planetary motion of the rollers, the invention designs a novel planetary roller screw planet cage structure. The invention can fix the transmission ratio of the differential planetary roller screw, and improve the stability and precision of the planetary movement of the rollers.

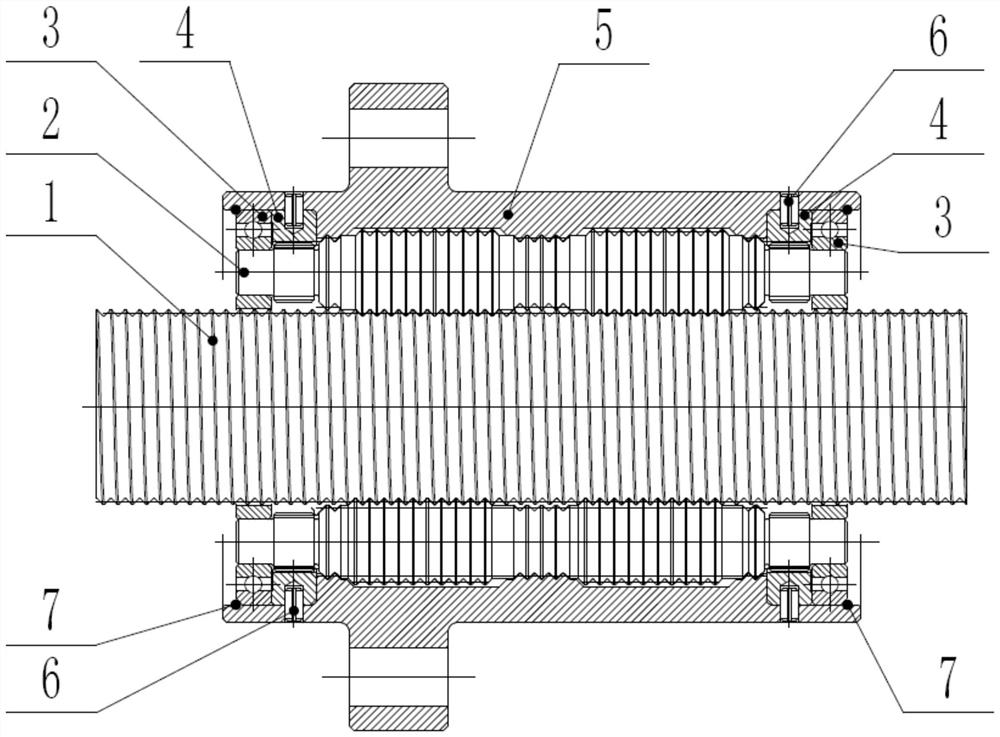

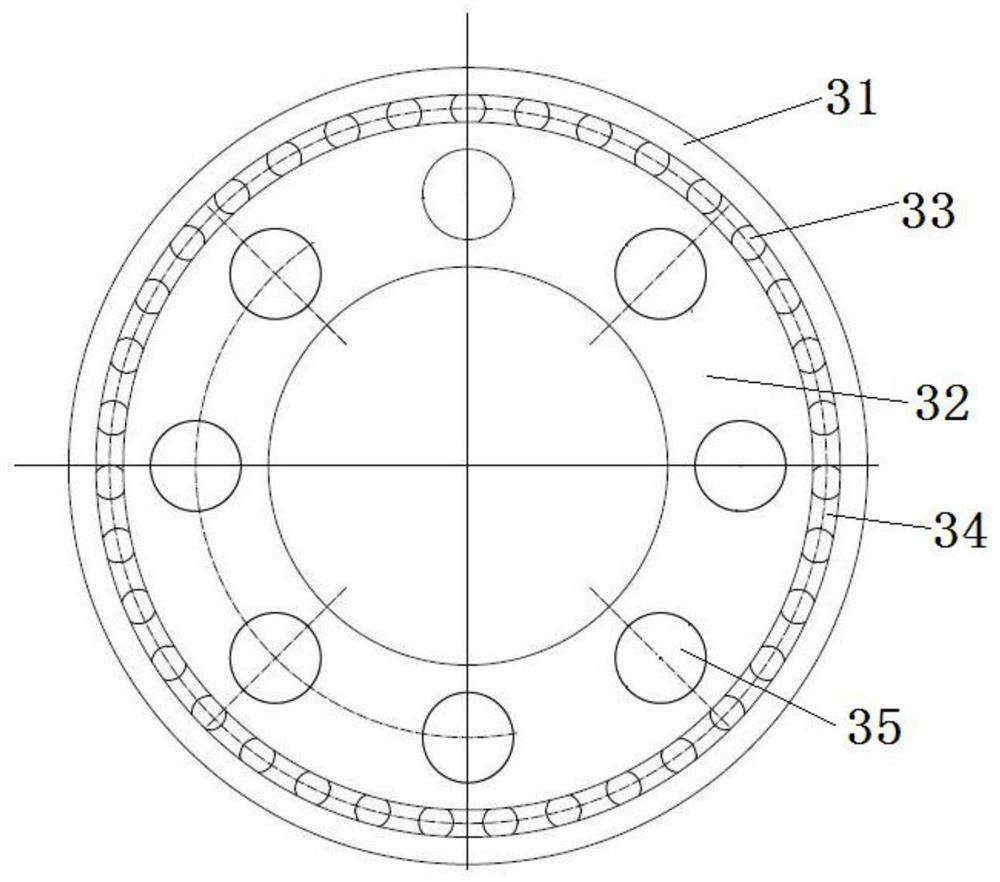

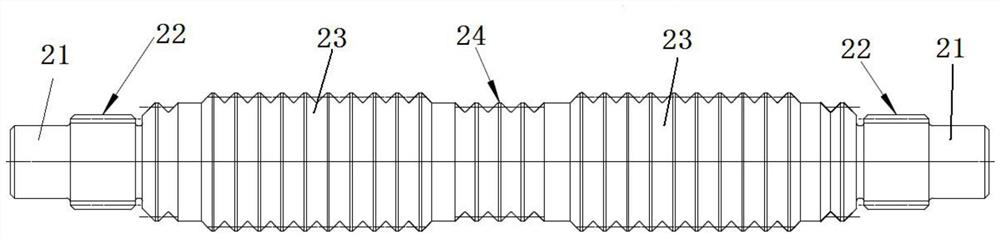

[0040] like figure 1 As shown, the planetary roller screw specifically includes a screw rod 1, two ring gears 4, a nut 5, two bearing cages 3, two wire lock rings 7, n rollers 2 and positioning pins 6; , the screw rod 1 is axially placed horizontally; n rollers 2 are evenly distributed on the outer wall of the screw rod 1 along the circumferential direction; the rollers 2 are threaded with the screw rod 1; the bearing cage 3 is a ring structure; 2 bearing cages 3 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com