An all-round planetary ball mill directly connected to a geared motor

A planetary ball mill and geared motor technology, applied in the field of powder grinding machinery, can solve the problems of increasing the overturning load and the bearing burden on the overturning shaft, affecting the bearing life, troublesome belt replacement, etc., achieving a simple structure, increasing service life, reducing wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

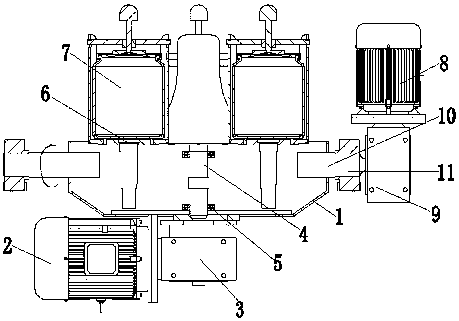

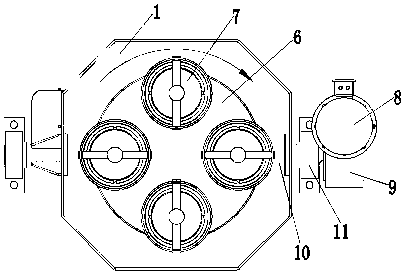

[0012] Such as figure 1 with figure 2 As shown, an omni-directional planetary ball mill directly connected to a geared motor includes a frame 1, a planetary motor 2, a transmission reducer 3, a transmission shaft 4, a planetary bearing 5, a turret 6, a grinding tank 7, a turning motor 8, Turning reducer 9, turning shaft 10 and turning bearing 11; the frame 1 is a symmetrical polygonal frame structure, the upper end of the frame 1 is provided with a regular octagonal or cylindrical mounting platform, the lower end of the frame 1 is provided with a bottom plate seat, and the bottom plate The seat is provided with a 90-degree Chinese font fixed frame; the planetary motor 2 is fixed on the 90-degree Chinese font fixed frame at the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com