A kind of mercapto-ene click prepared fluorine-containing azo surfactant and method

A technology of surfactants and fluorine-containing azo, which is applied in the field of synthesis of functional surfactants, can solve problems such as unfavorable cycle environmental protection, chemical pollution, etc., and achieve the effects of avoiding pollution damage, simple post-processing, and improving foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

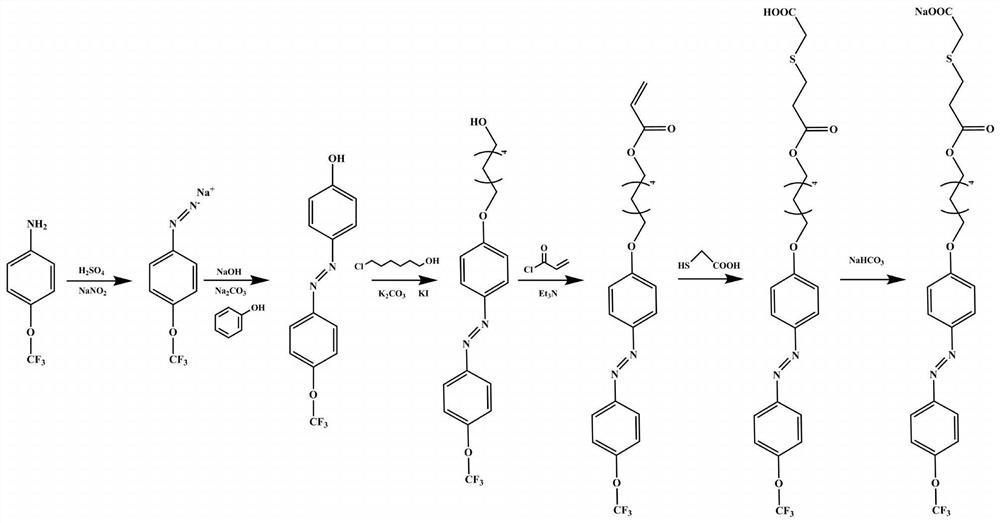

[0042] A kind of method for preparing fluorine-containing azo surfactant by mercapto-ene click, the synthesis schematic diagram is shown in figure 1 , including the following steps:

[0043] Step 1: Preparation of trifluoromethoxy azophenol;

[0044] (11) at about -5°C, dissolve trifluoromethoxyaniline in a mixture of 20ml of concentrated sulfuric acid and 20ml of distilled water, and stir evenly;

[0045] (12) To the above mixture, slowly add a solution containing water (56 mL) and sodium nitrite (5.020 g, 0.075 mol), and stir for 30 min;

[0046] (13) add phenol (0.075mol) dropwise to 2mol / L sodium hydroxide solution, mix well, then add to the above mixture, add anhydrous sodium carbonate (47g), and stir for 2h at pH 9-10;

[0047] (14) Neutralized with HCl to neutrality, the resulting mixture was filtered and washed with water. The crude product was dried and purified by recrystallization from ethanol to obtain the compound as a reddish-brown solid;

[0048] Step 2: Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com