Waste transfer truck capable of cleaning dustbins

A technology for trash cans and running vehicles, which is used in garbage cleaning, garbage collection, garbage storage, etc., can solve the problems of long time span, high work intensity, low efficiency, etc., so as to reduce work intensity, improve work efficiency, and improve time. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

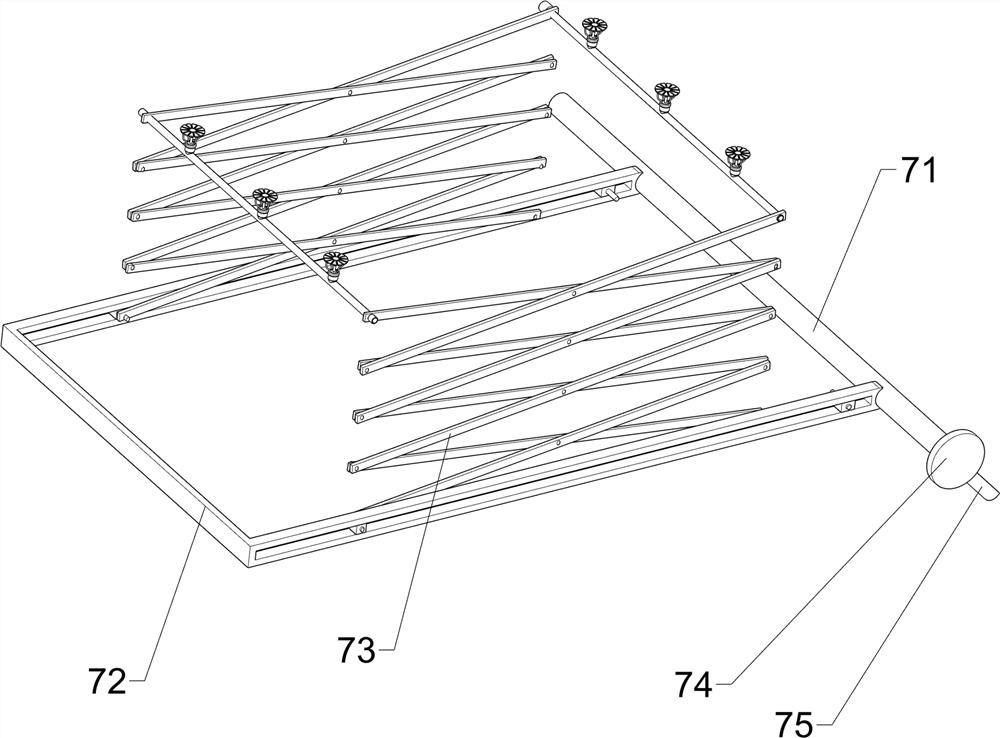

[0027] A garbage transfer vehicle that can clean garbage cans, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7 As shown, it includes a garbage truck 1, an unloading mechanism 2, a mounting plate 4, a collection tank 5, a cleaning mechanism 6, and a moving mechanism 7. The garbage truck 1 is equipped with an unloading mechanism 2 on the rear side of the top of the garbage truck. The side is connected with mounting plate 4, and the right side of mounting plate 4 is slidingly connected with collecting tank 5, and cleaning mechanism 6 is installed between collecting tank 5 and the left side of mounting plate 4 top, and moving mechanism 7 is provided in collecting tank 5.

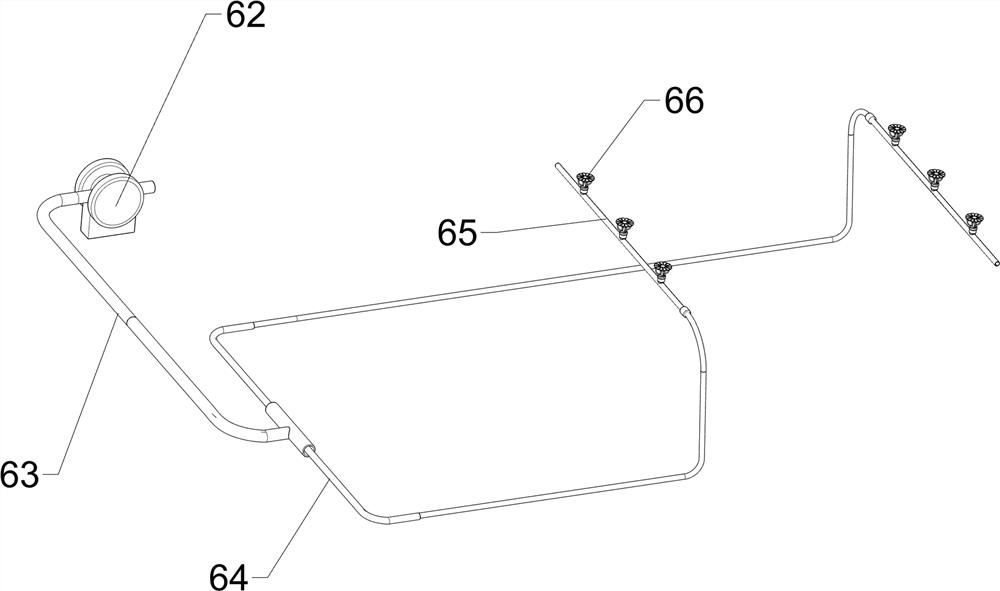

[0028] The cleaning mechanism 6 includes a water tank 61, a water pump 62, a water spray main pipe 63, a water spray branch pipe 64, a water outlet pipe 65 and a nozzle 66, a water tank 61 is installed on the left side of the top of the mounting plate 4, and a water pump 62 is i...

Embodiment 2

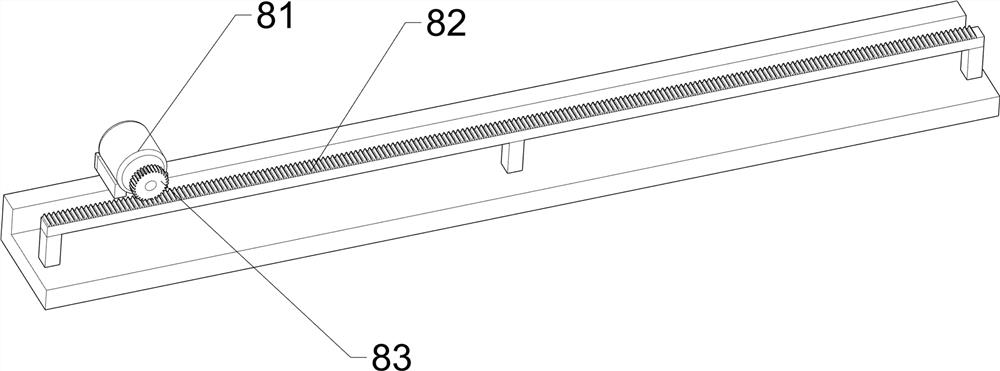

[0032] On the basis of Example 1, such as Figure 6 As shown, a propulsion mechanism 8 is also included, and the propulsion mechanism 8 includes a propulsion motor 81, a propulsion rack 82 and a propulsion gear 83, and a propulsion motor 81 is installed in front of the right side of the collection tank 5, and the propulsion motor 81 is connected with a propulsion gear 83, The right side of the top of the mounting plate 4 is connected with a propelling rack 82 , and the propelling gear 83 is engaged with the propelling rack 82 .

[0033] When the collecting tank 5 needs to move, start the propulsion motor 81 to rotate, and the propulsion gear 83 rotates thereupon, and the propelling gear 83 meshes with the advancing rack 82 to drive the collecting tank 5 to move backward. When it is parallel, the propulsion motor 81 stops. When all the cleaning actions are completed, the propulsion motor 81 is reversed to drive the collection tank 5 to reset, so that the movement effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com