An ultra-slender bellows forming device

A technology of forming device and bellows, which is applied to forming tools, feeding devices, positioning devices, etc., can solve the problems of length obstacles of bellows, high oil temperature of hydraulic system, and inability to manufacture stainless steel bellows, etc. Specialized production requirements and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

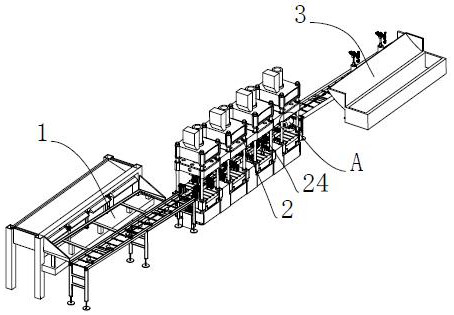

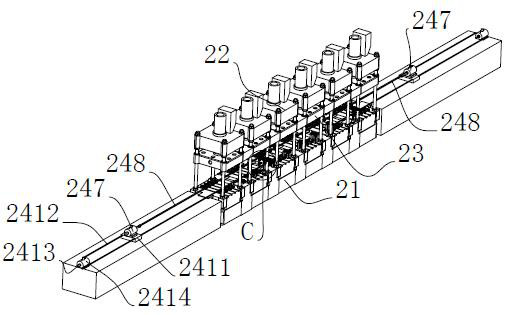

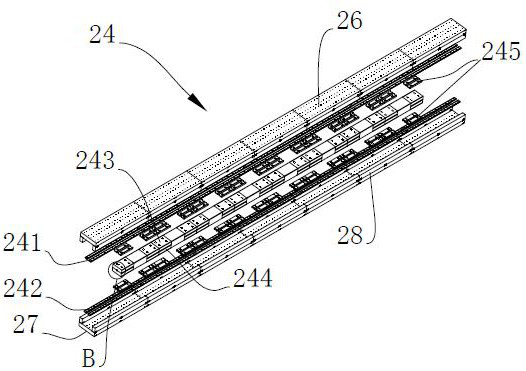

[0042] The present invention can be applied in the automatic forming assembly line of slender bellows, and the assembly line structure is as follows Figure 1 to Figure 23 As shown, it includes a self-weight feeding mechanism 1, a corrugated forming mechanism 2 and a self-weight unloading mechanism 3; the corrugated forming mechanism 2 here is also the structure of the present invention, including a workbench 21, which is provided with a hydraulic drive mechanism 22. The lower platen 23 and the forming mold 24, the two sides of the forming mold 24 are provided with mold side push cylinders 25, and the mold side push cylinders 25 apply axial thrust to the two ends of the forming mold 24 to complete the action of "squeezing waves" , the molding die 24 includes an upper mold rail 241 positioned at the lower side of the lower platen 23 and a lower mold rail 242 positioned at the upper side of the workbench 21, the upper mold rail 241 and the lower mold rail 242 are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com