SNCR system of same-pass cement kiln

A cement kiln, the same program technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of small flow rate, high working pressure of the spray gun, poor atomization effect, etc., and achieve the same total resistance loss and flow distribution Uniform, guaranteed denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

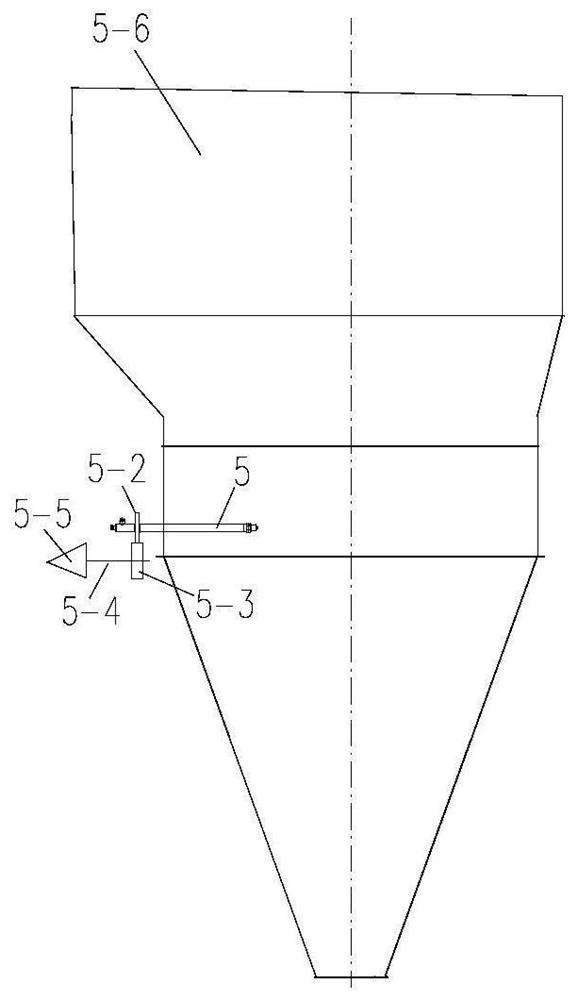

[0049] As attached to the manual figure 1 As shown, the simultaneous process cement kiln SNCR system includes reducing agent storage tanks, pumps, valves, flow meters, spray guns, compressed air tanks, valves, and simultaneous pipes.

[0050] Except for the spray gun with the longest pipe distance, the other spray gun has the same pipe. After adding the same pipe, the pipe length and the number of elbows of the two spray guns are the same, so the resistance of the two spray guns is the same, and the flow distribution is even. The working pressure of the spray gun is the same, and the atomization state is also the same. When the flow is controlled by frequency conversion or throttling, the resistance, flow rate, working pressure and atomization state between the two spray guns are also the same, and there will be no flow imbalance between the two spray guns.

[0051] For the manual attached figure 2 In the traditional SNCR system, due to the different pipe lengths and elbows...

Embodiment 2

[0054] As attached to the manual image 3 As shown, the spray gun and the spray gun gear are fixedly connected or the spray gun gear and the spray gun are integrated. The gear of the spray gun is engaged with the transmission gear. Transmission gear and transmission shaft, transmission shaft and the electric motor that has speed reducer are all conventional connections. The spray gun is driven to rotate by the motor with the reducer through the spray gun gear, the transmission gear, and the transmission shaft. The spray gun rotates at regular intervals under the drive of a motor with a reducer, and each rotation rotates at a specific fixed angle.

[0055] The rotatable cement kiln five-stage cylinder SNCR spray gun is arranged on the cyclone cylinder or the connection between the cyclone cylinder and the cyclone cone. The spray gun rotates every 30 minutes under the drive of the electric motor with a reducer, and each rotation is specific 180°.

Embodiment 3

[0057] As attached to the manual Figure 4 As shown, the unitized cement kiln SNCR system includes a reducing agent storage tank, a pump, a valve A, a flow meter, a spray gun, a compressed air tank, and a valve B. Each pump, valve A, flow meter, spray gun, and valve B form a control unit. Each control unit has 1 spray gun.

[0058] There are 3 control units, which are respectively arranged on the 3rd, 4th, and 5th floor platforms of the preheater tower at the end of the cement kiln. The spray guns in the same control unit are not affected by the height difference pressure of other spray guns.

[0059] The flow rate of the spray gun is adjusted by the frequency conversion of the pump or the opening of the valve in the same control unit.

[0060] According to different control requirements, the water flow rate of each control unit can be adjusted, and because the 8 control units are independent of each other, there is no mutual influence.

[0061] After this unitary cement ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com