Frost-resistant oil and preparation method thereof, chocolate and preparation method of chocolate

A technology of chocolate and oil, which is applied in the fields of edible oil/fat, cocoa, food science, etc. It can solve the problems of cumbersome operation process, inability to take into account the anti-frost effect and sensory quality, and achieve the effect of inhibiting frost and improving color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

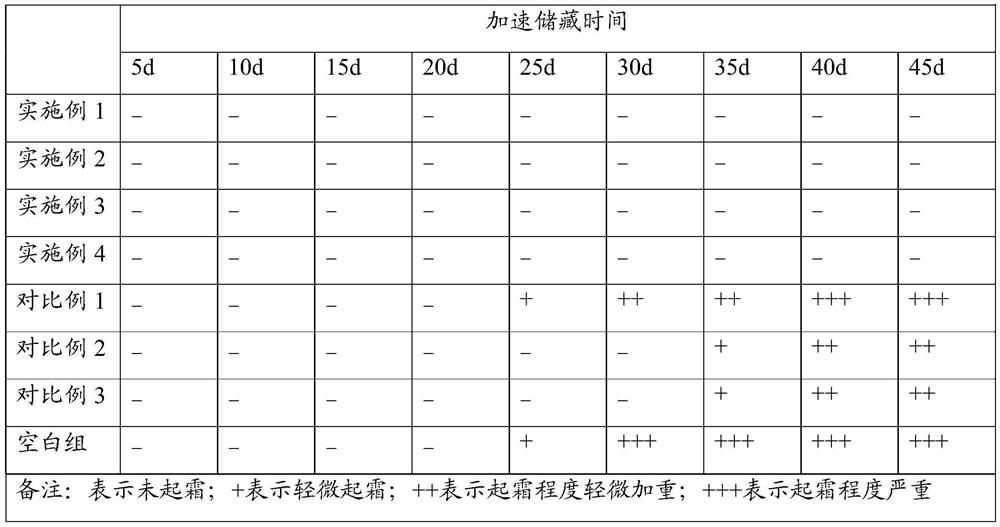

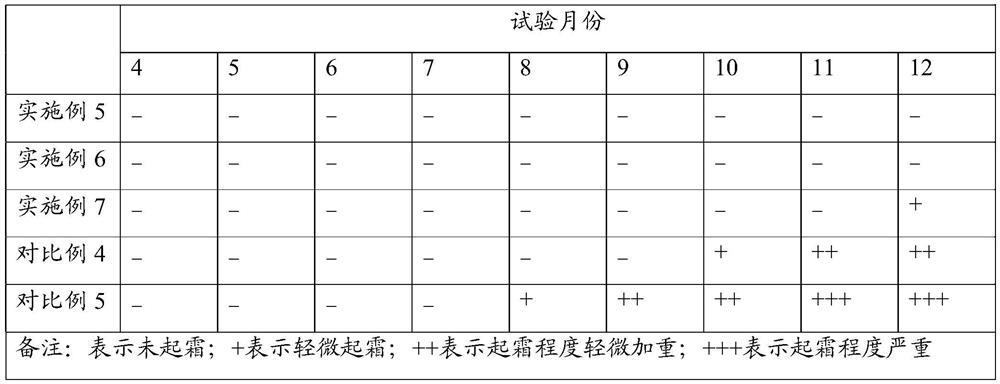

Examples

preparation example Construction

[0019] The embodiment of the present invention provides a kind of preparation method of anti-frost oil, the preparation method of described anti-frost oil comprises the following steps:

[0020] In step S101, the shea butter is subjected to three-stage fractionation treatment using an organic solvent as a medium to obtain three-stage stearin of shea butter.

[0021] In the embodiment of the present invention, the shea butter can be the oil extracted from the shea nut kernel by the conventional physical cold pressing method, or it can be purchased. The shea butter used in the embodiment of the present invention is purchased From Guangzhou Pukang Biotechnology Co., Ltd. Shea butter has a high content of unsaponifiables, high oil solubility, and is safe and non-toxic. After determination, its main components and contents include palmitic acid 71.112%, arachidic acid 16.611%, 11-eicosenoic acid 3.899%, myristic acid 3.091%, lauric acid 1.624%, behenic acid 1.263%, nonadecanoic ac...

Embodiment 1

[0045] Shea butter is subjected to three-stage fractionation treatment by 3-methylpentane, the ratio of solid to liquid is 1:5 (w:v), the stirring rate is controlled at 30r / min, and the temperature of the first stage fractionation is 1 ℃, kept for 60min; the temperature of the secondary fractionation was 4℃, kept for 125min; Take by weighing 5g shea butter three-grade stearin and oil-soluble tea polyphenols, hard palm oil and non-lauric acid cocoa butter mixture and place it in a magnetic stirring tank, said shea butter three-grade stearin and oil-soluble The mass ratio of tea polyphenols, hard palm oil and non-lauric cocoa butter substitutes is 26:3:4:13, adding 2% columnar candida in a mass percentage, and the magnetic stirring speed is 200r / min to carry out enzymatic For the transesterification reaction, the transesterification temperature is 55°C, and the transesterification time is 4 hours to obtain anti-frost grease.

Embodiment 2

[0047] Shea butter is subjected to three-stage fractionation treatment by 3-methylpentane, the solid-liquid ratio is 1:5 (w:v), the stirring rate is controlled at 30r / min, and the first-stage fractionation temperature is 2 ℃, keep 60min; secondary fractionation temperature is 5℃, keep 125min; tertiary fractionation temperature is 8℃, keep 200min, the yield rate of obtained shea butter tertiary stearin is 67%. Take by weighing 5g shea butter three-grade stearin and oil-soluble tea polyphenols, hard palm oil and lauric acid cocoa butter substitute mixture and place it in a magnetic stirring tank, said shea butter three-grade stearin and oil-soluble tea polyphenols The mass ratio of polyphenols, hard palm oil, and lauric cocoa butter substitute is 29:3:3:15, adding 3% columnar candidae in a mass percentage, and the magnetic stirring speed is 220r / min to carry out enzymatic transesterification Reaction, wherein, the transesterification temperature is 65°C, and the transesterificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com