Solution dehumidification and fresh water production combined system based on flash evaporation regeneration

A solution dehumidification, flash regeneration technology, applied in air conditioning systems, water supply devices, drinking water devices, etc., can solve the problem of increased energy consumption of dehumidification solutions, to avoid increased heating energy consumption, facilitate solidification, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

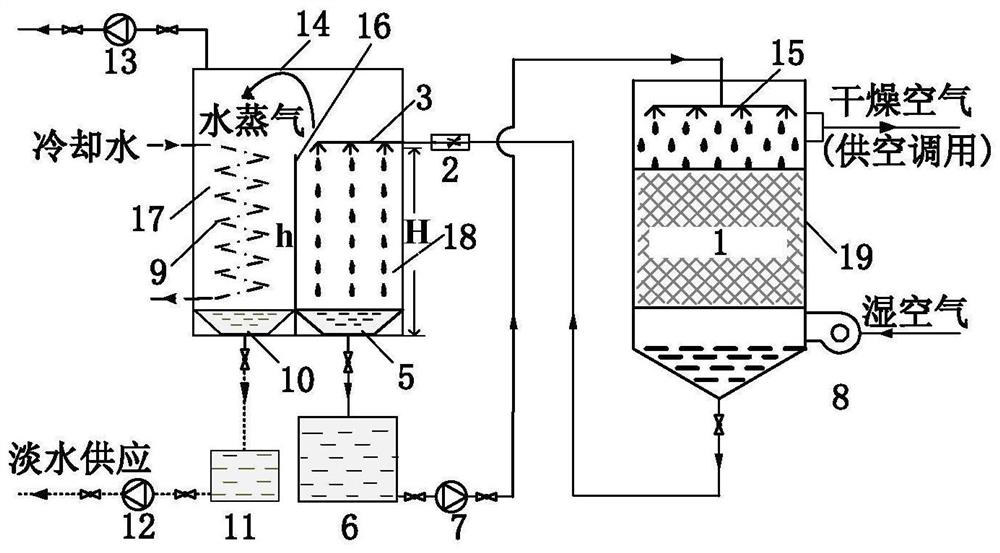

[0019] Such as Figure 1~2 As shown, the present invention is based on the flash regeneration solution dehumidification and fresh water production composite system, which can integrate the solution dehumidification and fresh water production into one system, and the solution regeneration and fresh water production are carried out in the low-pressure flash regenerator 14 at the same time The composite system of the present invention includes a solution dehumidification circulation loop composed of a dehumidifier 19 and a flash regenerator 14; a dehumidification filler 1 is provided in the dehumidifier 19, and a liquid distributor 15 is arranged on the top of the dehumidification filler 1, and the phase change dehumidification liquid passes through The liquid distributor 15 is sprayed on the dehumidification packing 1, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap