Repair device for large-diameter drainage pipes

A drainage pipe, large-diameter technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of heavy lining pipe weight and complicated construction, reduce the possibility of infiltration, reduce the use of large equipment, the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

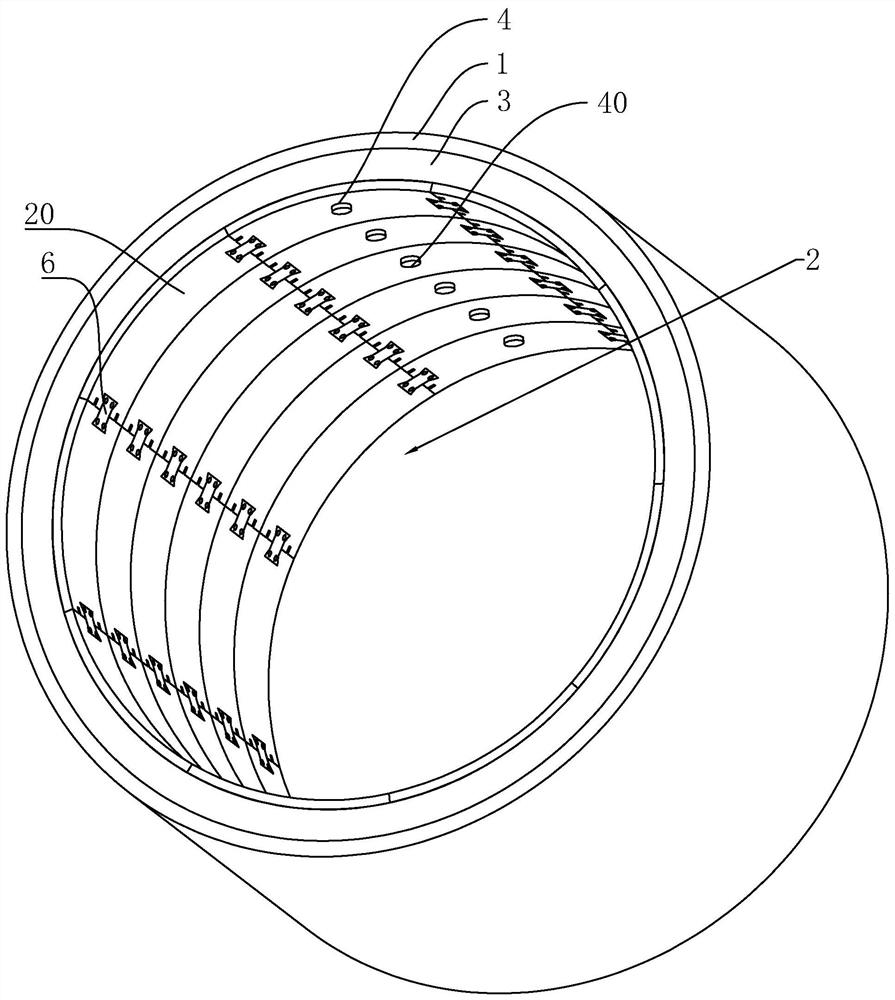

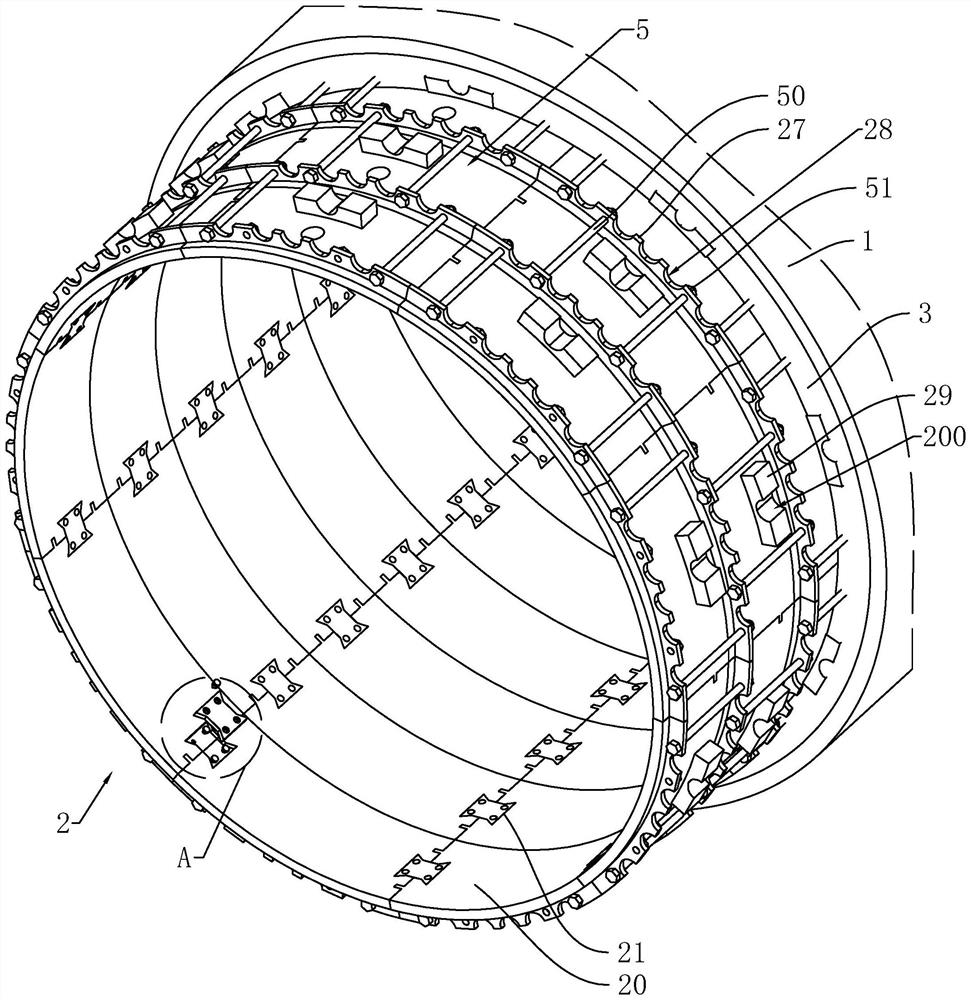

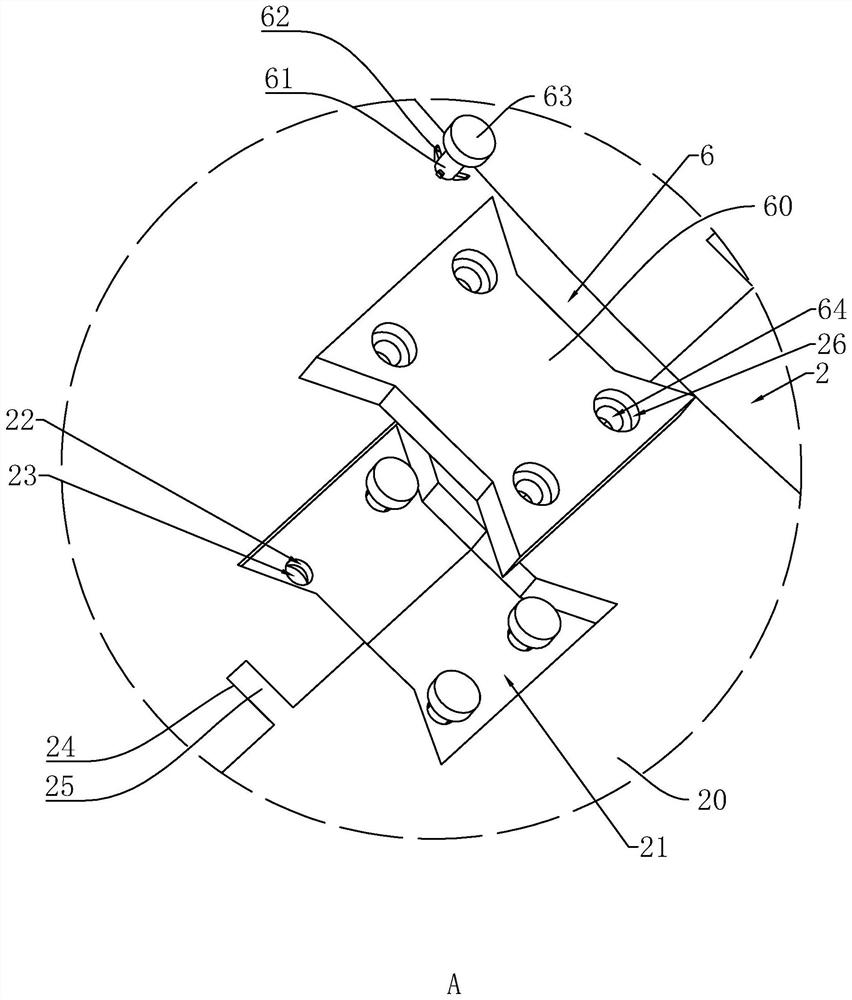

[0051] refer to figure 1 , a repairing device for large-diameter drainage pipes, which comprises a plurality of arc-shaped plates 20 attached to the inner side wall of the drainage pipe 1, a plurality of arc-shaped plates 20 are arranged along the circumferential direction of the drainage pipe 1, and the arc-shaped plates 20 It is a transparent PVC arc-shaped plate 20, which is convenient to observe the pouring of the grouting material.

[0052] refer to figure 1 and figure 2 , the adjacent arc-shaped plates 20 are connected by the connecting piece 6, a plurality of arc-shaped plates 20 constitute a node ring lining 2, and a plurality of node ring linings 2 are arranged in the drainage pipe 1 and along its axial direction, and the adjacent ring linings 2 Connected by the mounting member 5, a grouting material layer 3 is provided between the ring lining 2 and the drainage pipe 1. The grouting material is preferably micro-expanded high-strength grouting material, and the gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com