Axial force balance structure of boost air flotation turbine cooler

A technology of turbine cooler and balanced structure, which is applied in the cooling of turbine/propulsion device, engine cooling, non-variable pump, etc. It can solve problems such as unfavorable rotor starting, accelerated bearing wear, and shortened bearing service life. Achieve the effect of solving the floating problem of the booster air bearing turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

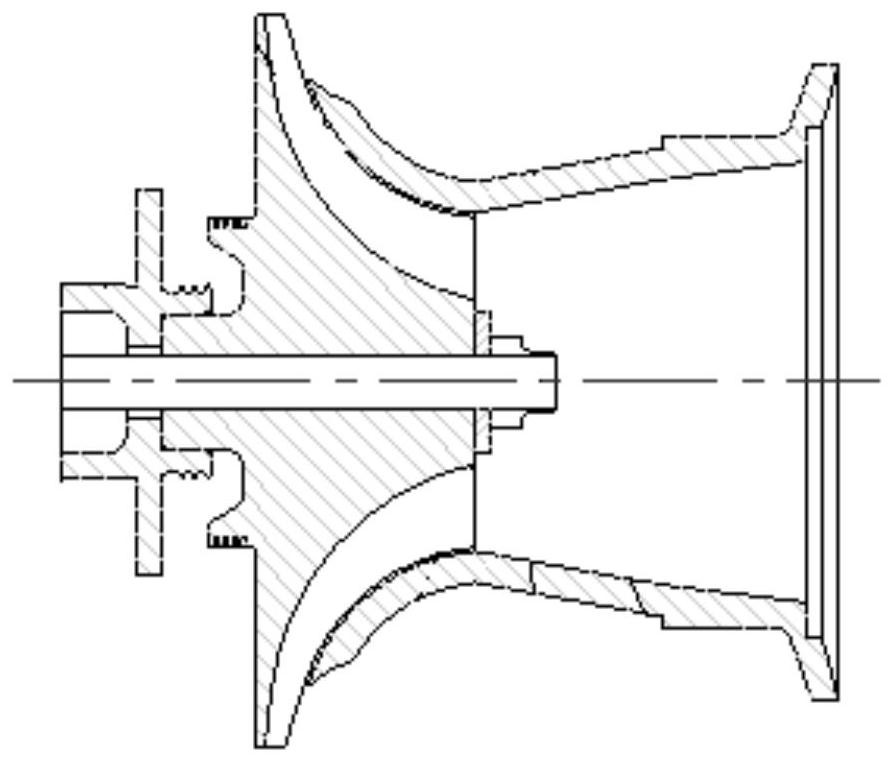

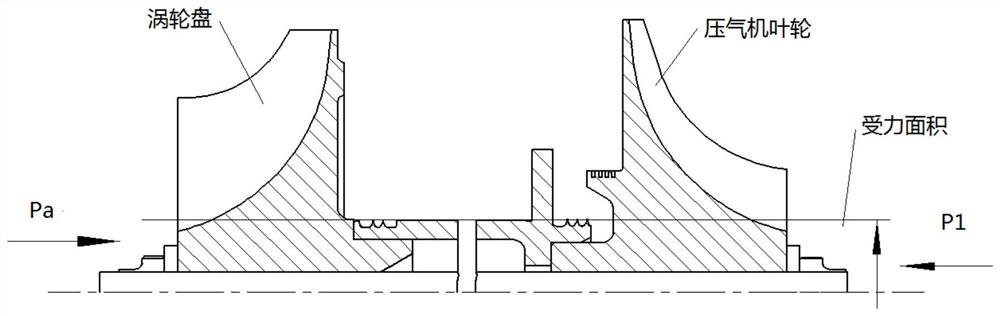

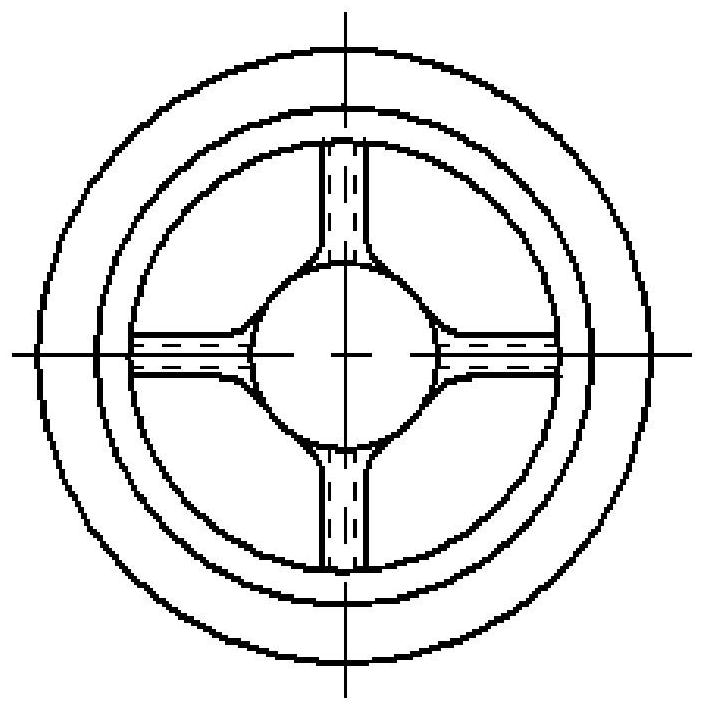

[0017] The present invention will be described in further detail below. see image 3 , the structure of the axial force balance of the aviation booster air flotation turbine cooler is shown in image 3 , which consists of compressor volute 1, compressor impeller 2, shaft 3, dynamic sealing ring 4, self-locking nut 5 and tie rod 6. The compressor impeller 2 is pressed into the shaft 3 hole, the tie rod 6 passes through the shaft 3 and the compressor impeller 2, the self-locking nut 5 is installed on the tie rod 6, and compresses the dynamic sealing ring 4; the compressor volute 1 is fixed by screws in the shell;

[0018] A dynamic sealing ring 4 is added to the shaft head of the compressor impeller 2, and a guide device is arranged at the inlet of the compressor volute 1, and a hole is opened in the middle of the device to form a seal with the dynamic sealing ring 4. The ribs of the flow guiding device are provided with pressure relief holes communicating with the outside in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com