Automatic wind turbine generator fixing device

A technology for wind turbines and fixtures, which is applied in the assembly of wind turbines, the configuration of installation/support of wind turbines, and wind power generation, etc., can solve the problem of increasing installation and operation costs of offshore wind turbines, increasing installation costs, and wasting installation time. problems, to achieve the effect of reducing installation and operation costs, facilitating adjustment, and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

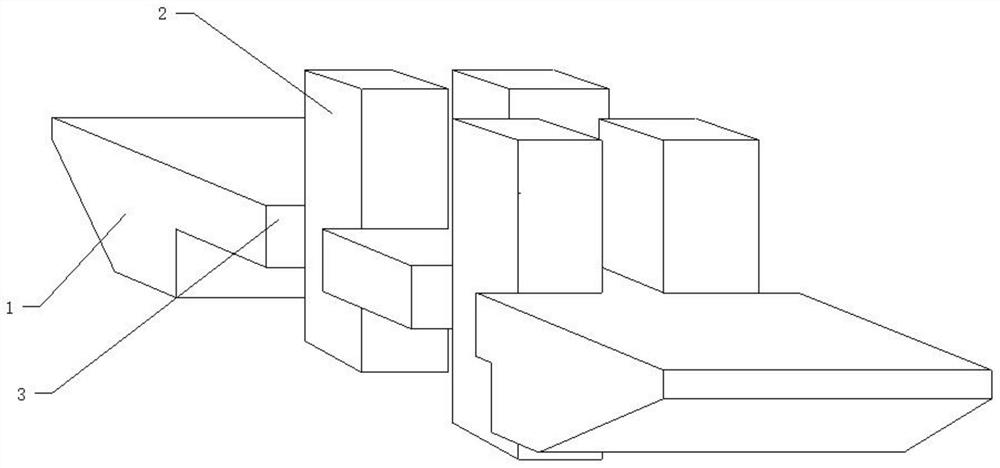

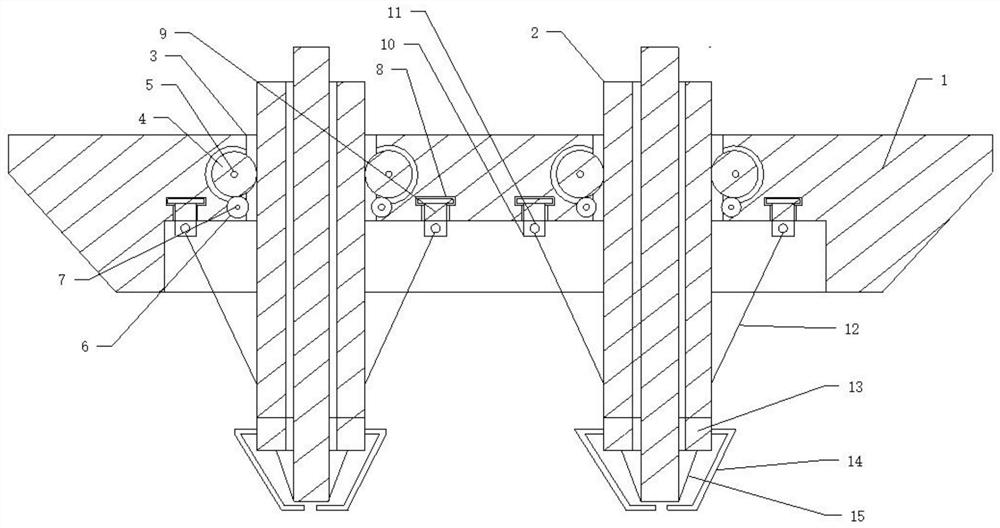

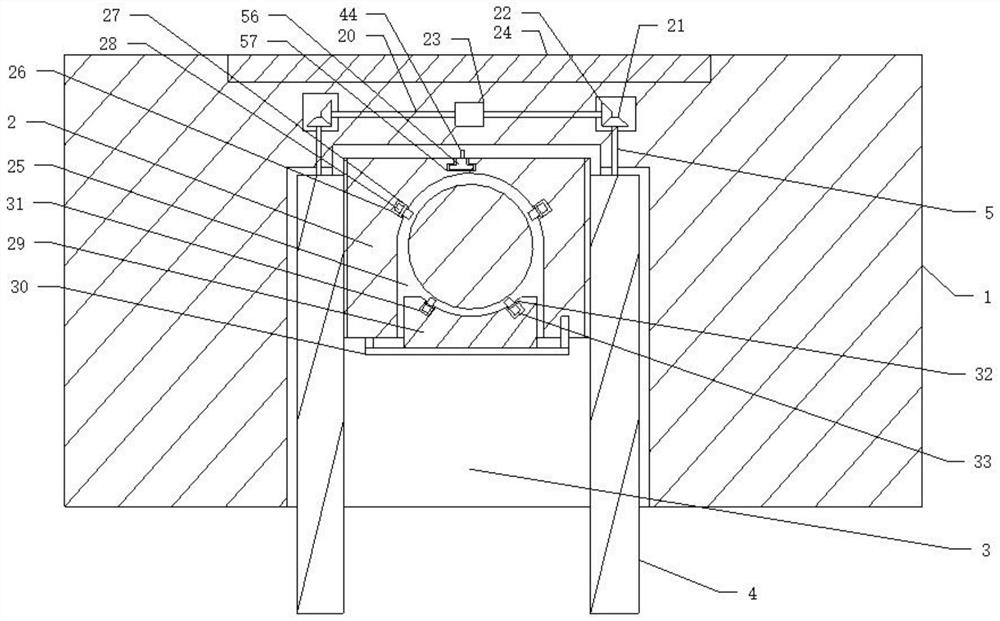

[0035] Such as Figure 1 to Figure 9 As shown, an automatic fixing device for a wind power generator includes a hull 1, with hull side grooves 3 provided on both sides of the hull 1, and a vertical support tube 2 that slides vertically in the hull side groove 3, A support base 13 is provided at the bottom of the vertical support cylinder 2, a support cylinder groove 25 is provided on the vertical support cylinder 2, and a wind support cylinder 19 is provided in the support cylinder groove 25. 2 is also provided with a swinging lock block 29, the lock block 29 restricts the swing of the wind support cylinder, the conveying support cylinder 2 is provided with a rotating control shaft 40, the control shaft 40 controls the The swing of the lock block 29 is described.

[0036] The hull 1 can float on the water. Hull side tanks 3 are provided on both sides of the hull 1. The number of hull side tanks 3 is set according to the needs of the design, and a vertical set is provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com