Construction method and application of fabricated concrete road plate

A technology for concrete roads and construction methods, which is applied in the direction of roads, roads, special pavement, etc., can solve the problems of energy saving and emission reduction, a large amount of construction waste, long construction period, etc., and achieve easy professional organization, rapid assembly, and mold making simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

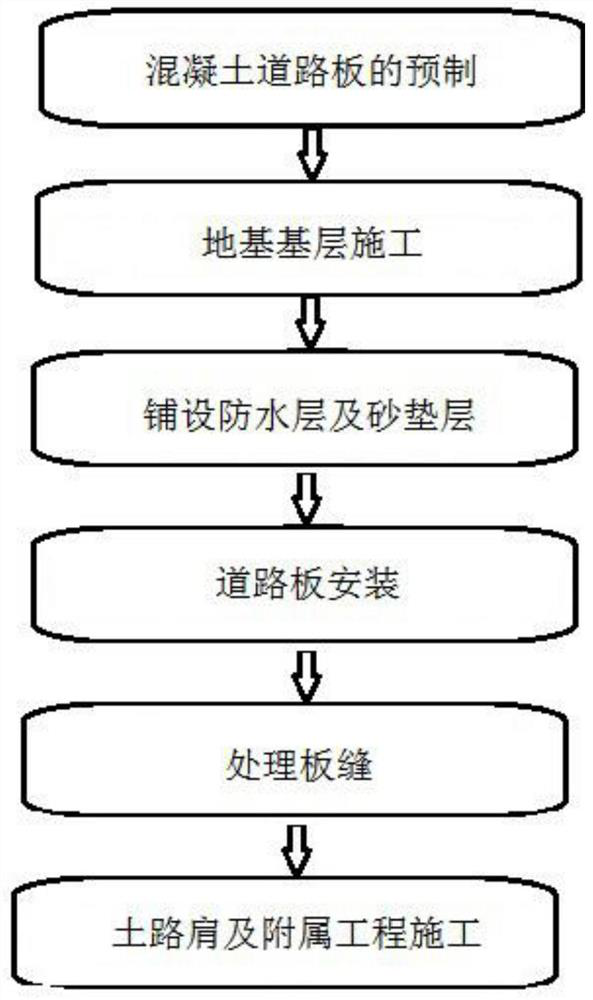

[0046] refer to figure 1 A construction method for a prefabricated concrete road slab shown, comprising the following steps

[0047] Step 1: Prefabrication of concrete road slabs;

[0048] Step 2: foundation base construction;

[0049] Step 3: laying waterproof layer and sand cushion

[0050] After step 2 is completed, a waterproof layer is laid on the prepared foundation base, and after the waterproof layer is laid, a sand cushion is laid on the waterproof layer;

[0051] Step 4: Road Slab Installation

[0052] After step 3 is completed, the concrete road slab prefabricated in step 1 is transported to the paving site for assembly;

[0053] Step 5: Handle the board seams;

[0054] Step 6: Construction of earth shoulders and ancillary works.

[0055] In actual use, set the length and width of the precast concrete road slab according to the actual conditions of the construction section, transportation conditions, load level and the environment of the construction site, mak...

Embodiment 2

[0080] refer to figure 1 The construction method of a prefabricated concrete road slab shown is different from the first embodiment in that: the prefabricated concrete road slab in the first step is made by the following method

[0081] Step 1: Make a Template

[0082] Make a formwork with an aspect ratio of 1 to 3 for precast concrete road slabs, apply a release agent evenly on the formwork, and uniformly fix and connect two connecting hole molds at both ends of the formwork bottom along the radial direction;

[0083] The second step: install the steel skeleton of the precast concrete road slab in the formwork;

[0084] Step 3: Locate the hanger on the steel frame

[0085] Four hanging parts are respectively fixed on the upper and lower bottom surfaces of the steel frame, and the four hanging parts are evenly and symmetrically arranged on the steel frame;

[0086] The fourth step: concrete vibration;

[0087] Step 5: Lifting and health preservation of demoulding flap

[...

Embodiment 3

[0097] refer to figure 1 The construction method of a prefabricated concrete road slab shown is different from Embodiment 1 or 2 in that: the construction method of graded crushed stone is adopted in the construction of the foundation base in Step 2, and the mixture is made of 20-30mm Crushed stone, 10-20mm gravel, 5-10mm gravel and stone chips are mixed according to the ratio of 15:35:15:35, and the water content in the mixture is 5%-6%.

[0098] In actual use, in order to ensure the mixing quality, it is necessary to use the factory mixing method for centralized mixing, use the existing technology paver to pave the reference wire rope, vibratory roller and rubber wheel roller for rolling; strictly control the content of the mixture during construction. The amount of water is 5%-6% to ensure a better compaction effect of the graded crushed stone layer.

[0099] The construction quality of graded crushed stone is the key project of pavement installation and use, which directl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com