Hydraulic vibration exciter

A technology of hydraulic exciter and shock wave, which is applied in the direction of vibrating fluid and fluid pressure actuating device, etc. It can solve the problems of large working resistance, difficult processing, unsuitable working environment with harsh conditions, etc., and achieves amplitude and The effect of stable vibration frequency, fast output response speed, smooth start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

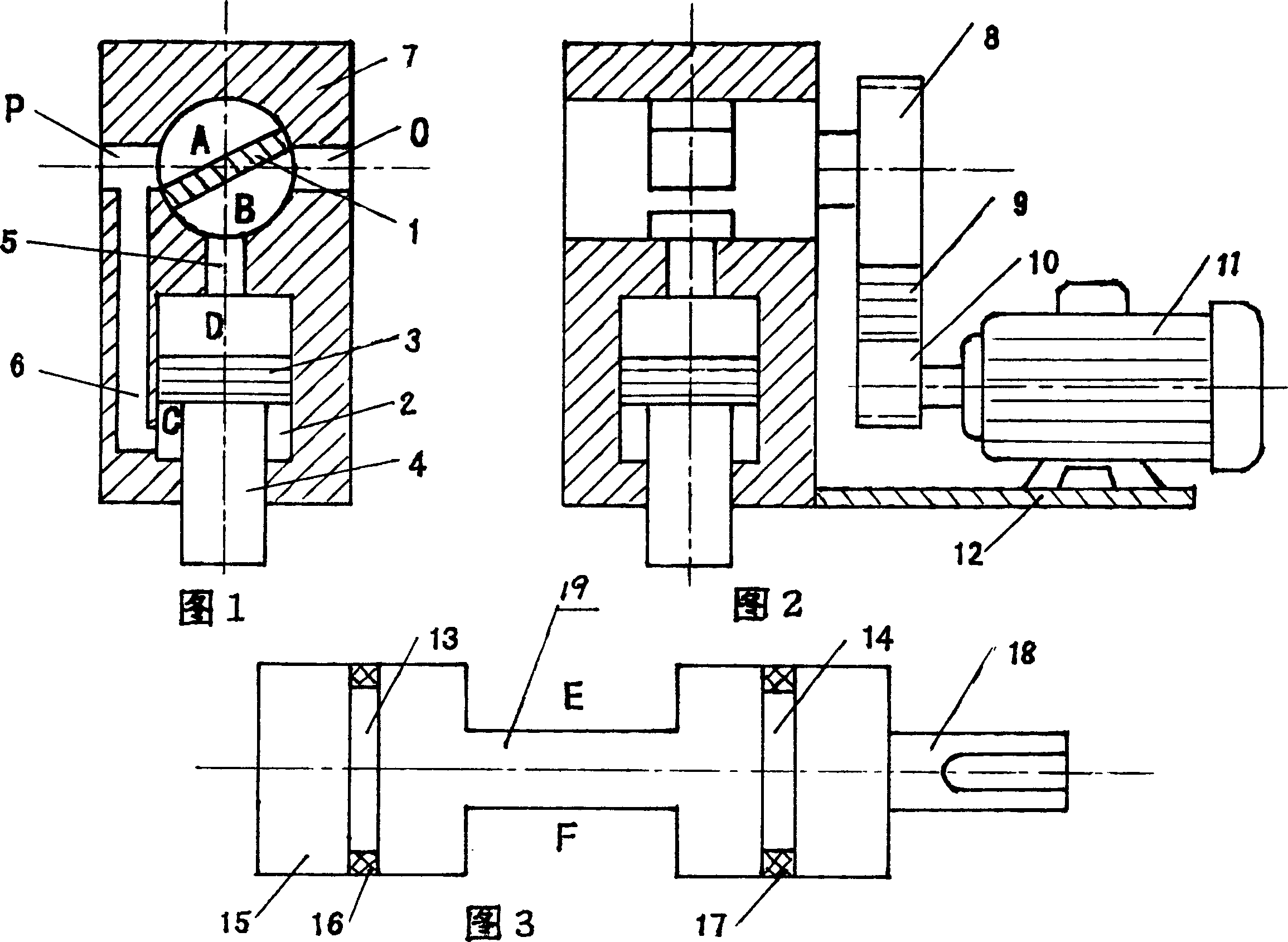

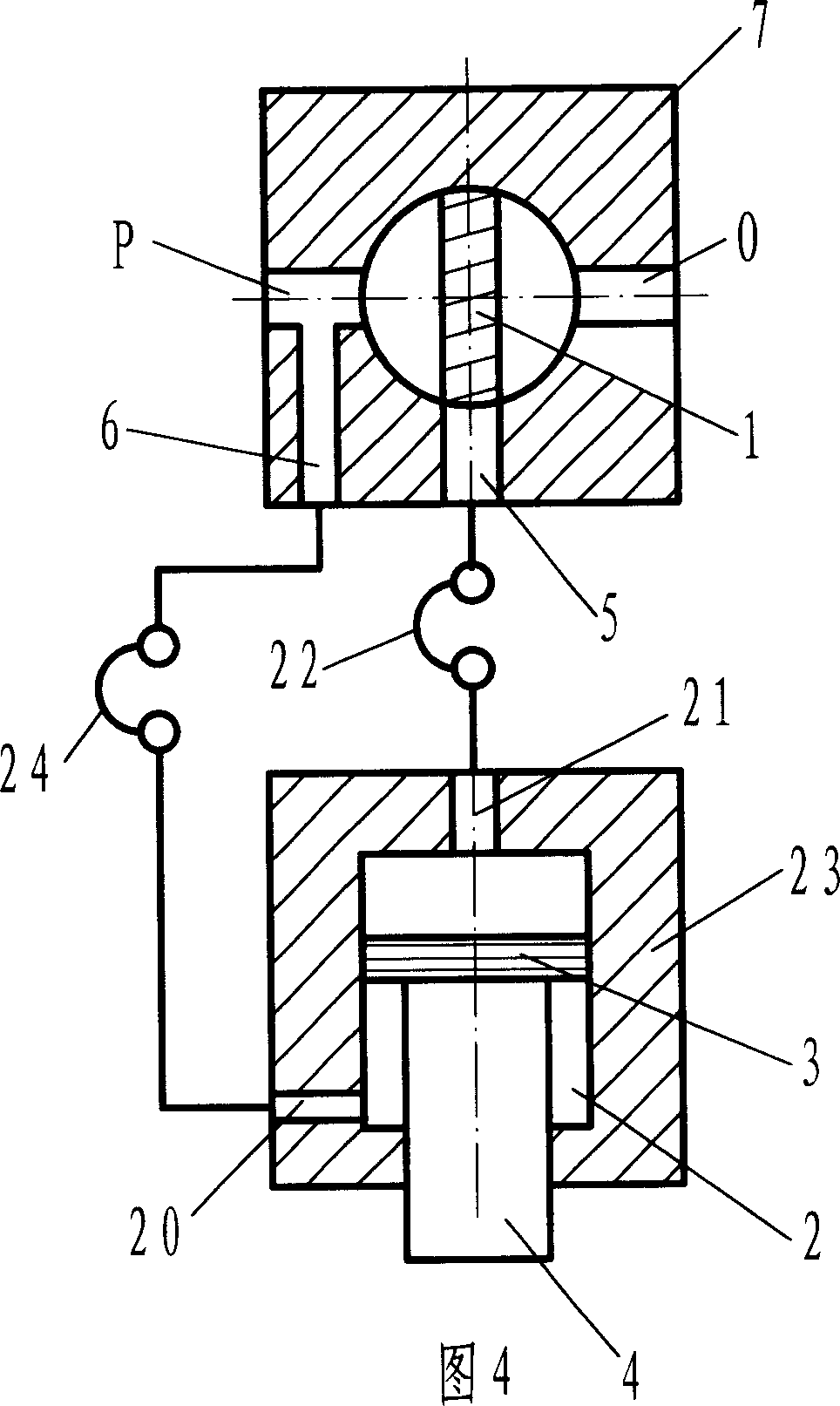

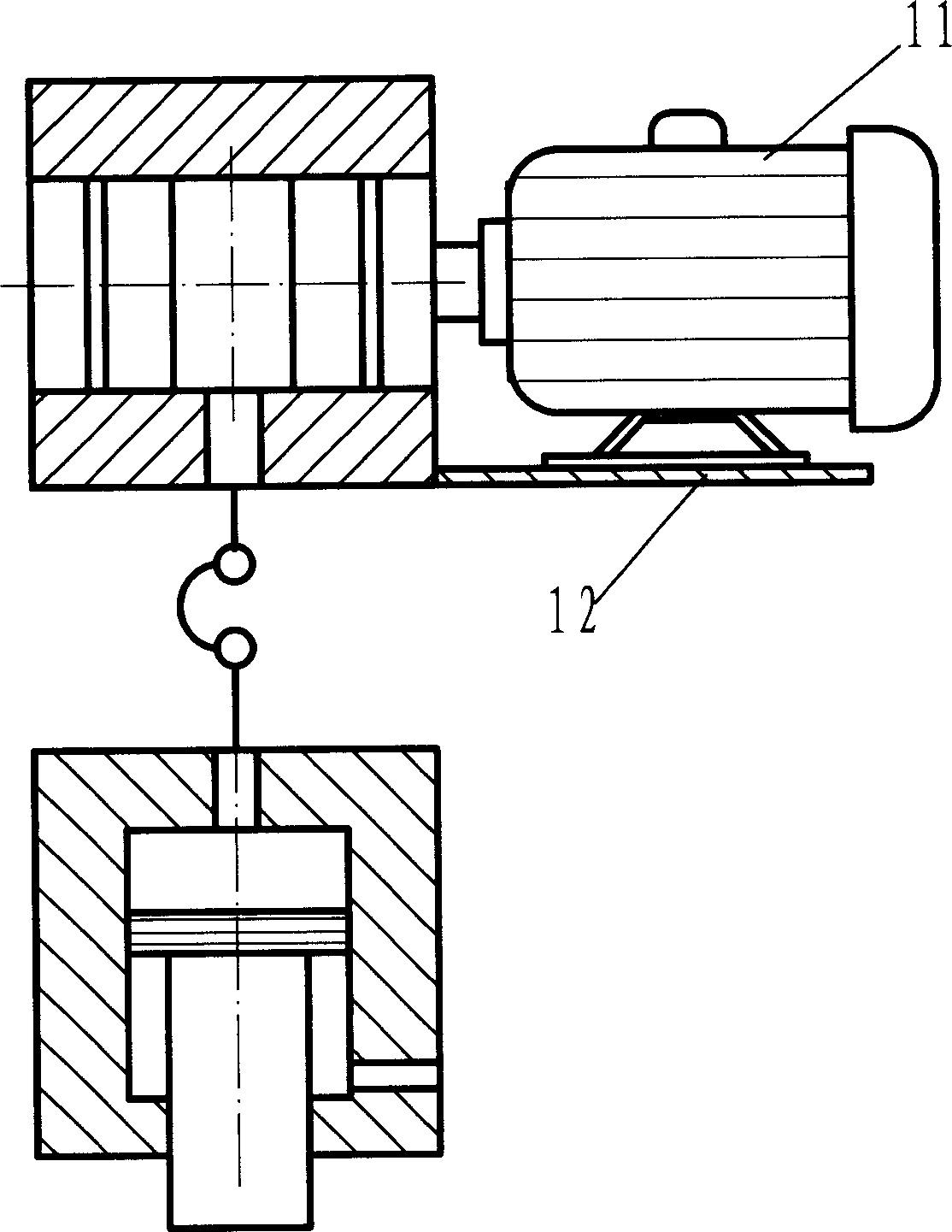

[0023] The hydraulic exciter shown in Fig. 1 and Fig. 2 is composed of a shock wave device 1, a hydraulic cylinder 2, a housing 7 and a drag element 11 of a drag device, a large pulley 8, a small pulley 10, a transmission belt 9, and a base 12 and so on. The shock wave device 1 is installed in the casing 7 and is located at the upper part of the piston cavity D of the hydraulic cylinder 2 . The casing 7 is provided with liquid holes 5 and 6 , and the shock wave 1 and the hydraulic cylinder 2 are communicated through the liquid holes 5 . The liquid hole 6 communicates with the high-pressure liquid inlet P and the piston rod cavity C of the hydraulic cylinder 2 . The high-pressure liquid inlet P, the liquid return port O and the liquid passage hole 5 are designed in the housing 7 on the same cross section, and the diameters of the three holes are equal. The high-pressure liquid inlet P and the liquid return port O are designed on the same center line, 180 degrees to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com