A cleaning agent for silicone rubber composite insulators

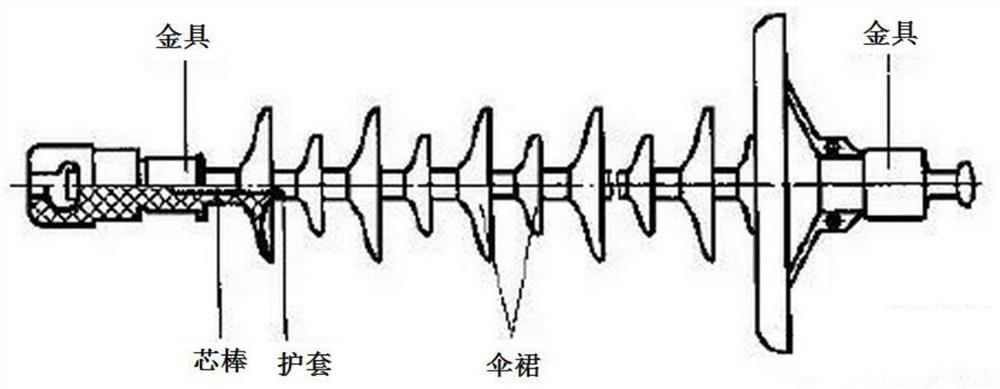

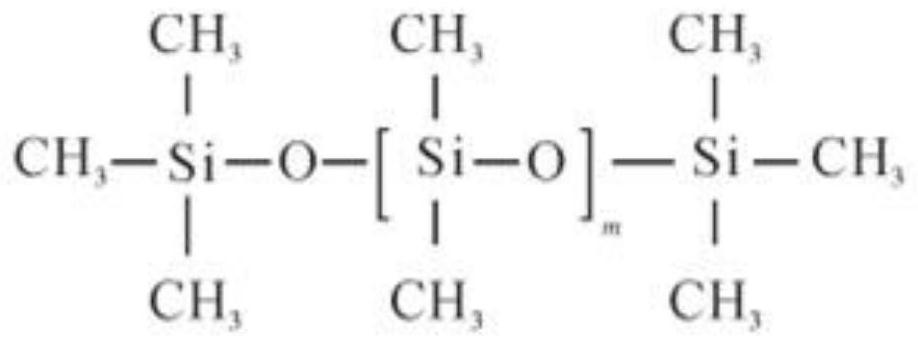

A composite insulator and silicone rubber technology, which is applied in the direction of detergent composition, surface active detergent composition, cationic surface active compound, etc., can solve the problems such as unsatisfactory cleaning effect of composite insulator silicone rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

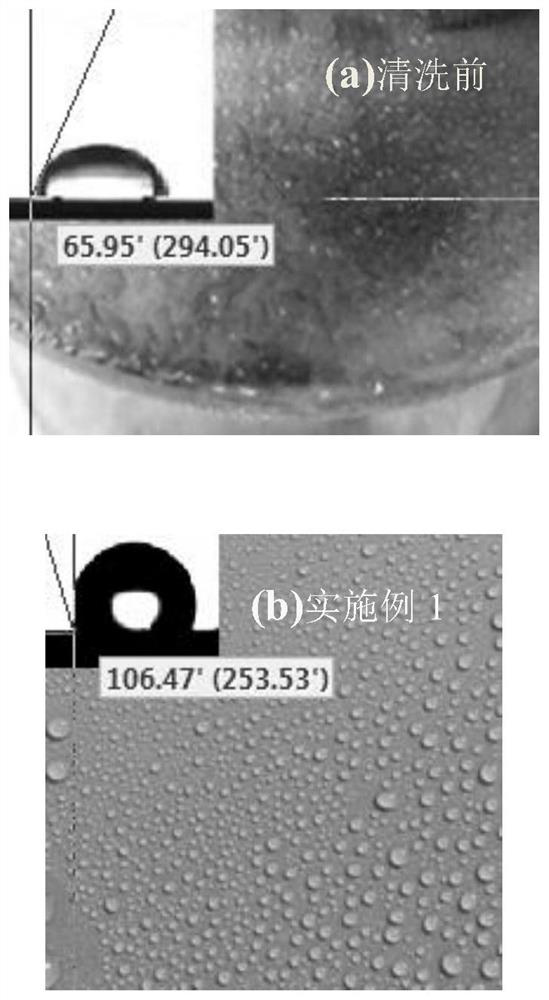

Examples

Embodiment 1

[0062] Weigh each agent according to the following mass:

[0063] Acetyl aminoglycoside: 400g;

[0064] Methallyl polyoxyethylene ether: 100g;

[0065] Didecyldimethylammonium chloride: 10g;

[0066] Sodium lauryl sulfate: 10g;

[0067] 480g of water.

[0068] Mix the above-mentioned components in a plastic bucket, and stir the cleaning solution clockwise with a wooden stick to completely dissolve the components. What is finally formulated is a cleaning agent for silicone rubber composite insulators of the present invention.

Embodiment 2

[0070] Compared with Example 1, the dosage ratio of the penetrant methallyl polyoxyethylene ether is reduced in this example, and each agent is weighed according to the following mass:

[0071] Acetylaminoglycoside: 470g;

[0072] Methallyl polyoxyethylene ether: 30g;

[0073] Didecyldimethylammonium chloride: 10g;

[0074] Sodium lauryl sulfate: 10g;

[0075] 480g of water.

[0076] Mix the above components in a plastic bucket, and stir the cleaning solution clockwise with a wooden stick to dissolve the components completely. If the weather is cold, heat the water to 30-50°C before mixing and stirring to promote the separation of the components. Dissolves quickly. What is finally formulated is a cleaning agent for silicone rubber composite insulators of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com