Fertilizer for preventing and treating fruit cracking and preparation method thereof

A fertilizer and fruit cracking technology, applied in the direction of inorganic fertilizers, calcium fertilizers, fertilizer mixtures, etc., can solve the problems affecting fruit sweetness, fullness, fruit coloring, etc., and achieve the effect of reducing cracking, reducing cracking, and avoiding antagonistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

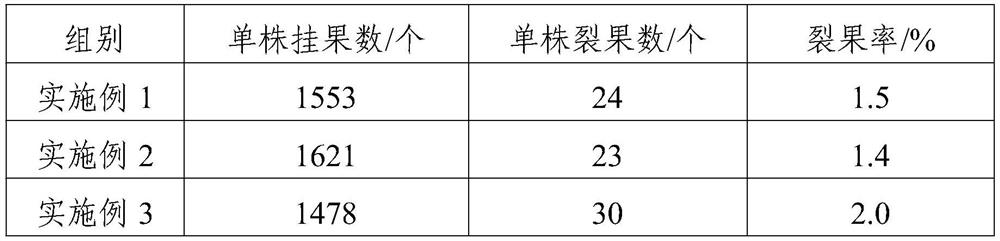

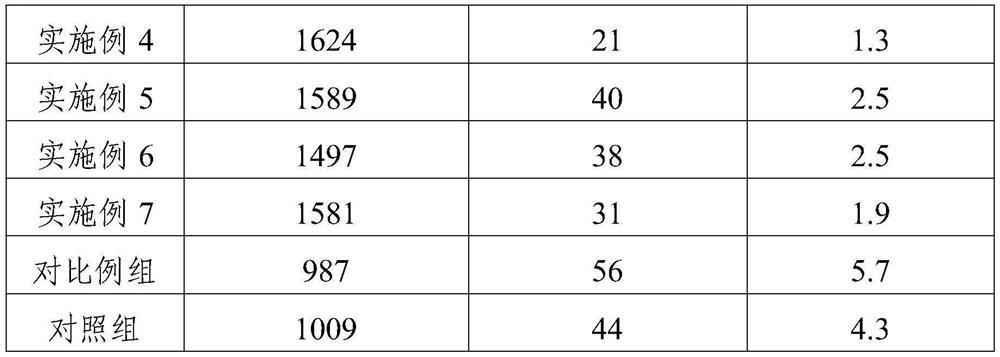

Embodiment 1

[0027] A fertilizer for preventing fruit cracking, comprising the following raw materials in parts by weight: 40 parts of potassium fertilizer, 25 parts of ammonium polyphosphate, 10 parts of inorganic calcium salt, 8 parts of diatomite particles, 5 parts of trace elements, 0.1 part of niacin, and 100 parts of water.

[0028] Inorganic calcium salts include calcium chloride, calcium gluconate, and calcium dihydrogen phosphate, and calcium chloride, calcium gluconate, and calcium dihydrogen phosphate are mixed in a mass ratio of 1:1:2; trace elements include zinc, manganese, magnesium, and molybdenum , and zinc, manganese, magnesium and molybdenum are mixed in a mass ratio of 1:1:1:1; ammonium polyphosphate is ammonium polyphosphate with a low degree of polymerization, and the degree of polymerization of ammonium polyphosphate is 10-15.

[0029] The preparation method of the above-mentioned fertilizer for preventing and controlling fruit cracking specifically comprises the follo...

Embodiment 2

[0035] A fertilizer for preventing fruit cracking, comprising the following raw materials in parts by weight: 42 parts of potassium fertilizer, 26 parts of ammonium polyphosphate, 12 parts of inorganic calcium salt, 10 parts of diatomite particles, 6 parts of trace elements, 0.2 parts of niacin and 110 parts of water.

[0036] Inorganic calcium salts include calcium chloride, calcium gluconate, and calcium dihydrogen phosphate, and calcium chloride, calcium gluconate, and calcium dihydrogen phosphate are mixed in a mass ratio of 1:1:2; trace elements include zinc, manganese, magnesium, and molybdenum , and zinc, manganese, magnesium and molybdenum are mixed in a mass ratio of 1:1:1:1; ammonium polyphosphate is ammonium polyphosphate with a low degree of polymerization, and the degree of polymerization of ammonium polyphosphate is 10-15.

[0037] The preparation method of the above-mentioned fertilizer for preventing and controlling fruit cracking specifically comprises the foll...

Embodiment 3

[0043] A fertilizer for preventing fruit cracking, comprising the following raw materials in parts by weight: 44 parts of potassium fertilizer, 26 parts of ammonium polyphosphate, 14 parts of inorganic calcium salt, 12 parts of diatom ore particles, 6 parts of trace elements, 0.3 parts of niacin, and 110 parts of water.

[0044]Inorganic calcium salts include calcium chloride, calcium gluconate, and calcium dihydrogen phosphate, and calcium chloride, calcium gluconate, and calcium dihydrogen phosphate are mixed in a mass ratio of 1:1:2; trace elements include zinc, manganese, magnesium, and molybdenum , and zinc, manganese, magnesium and molybdenum are mixed in a mass ratio of 1:1:1:1; ammonium polyphosphate is ammonium polyphosphate with a low degree of polymerization, and the degree of polymerization of ammonium polyphosphate is 10-15.

[0045] The preparation method of the above-mentioned fertilizer for preventing and controlling fruit cracking specifically comprises the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com