Easily-degradable high-concentration industrial wastewater treatment method and system

A high-concentration wastewater and industrial wastewater technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as failure to meet effluent standards, biochemical system sludge expansion, and long system start-up period. Achieve the effect of ensuring the effect of biochemical treatment, increasing the sedimentation rate, and improving the ability of biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, a breeding enterprise in Hebei discharges 100 m3 / d of breeding wastewater. The wastewater has high CODcr value (COD≤3000mg / L), high ammonia nitrogen content (NH4-N≤500mg / L), high total phosphorus content (TP≤50mg / L), and high suspended solids content (SS≤1000mg / L).

[0038] Effluent standard: COD<200mg / L, NH4-N<80mg / L, TP<8mg / L, SS<100mg / L.

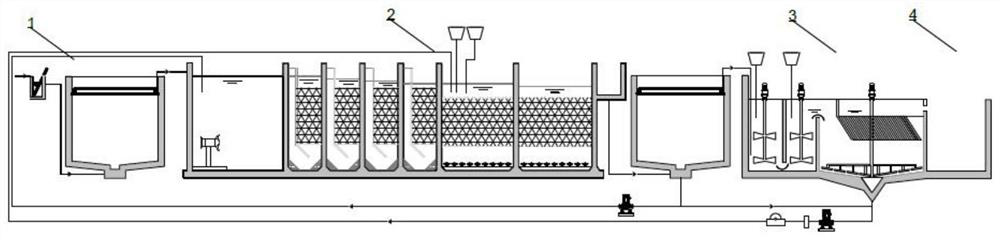

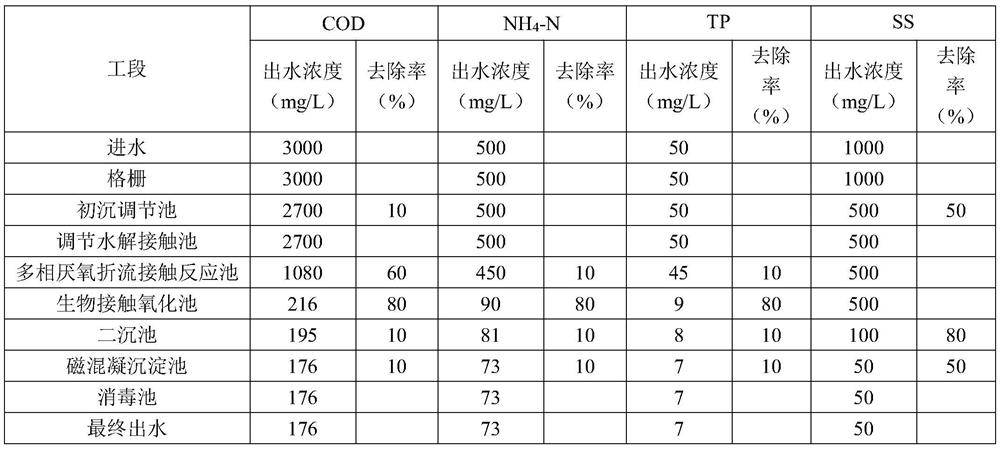

[0039] Wastewater is treated by using the easily degradable high-concentration industrial wastewater treatment system of the present invention. The wastewater treatment system sequentially includes a grid, a primary sedimentation adjustment tank, an integrated biochemical treatment device for high-concentration wastewater, a magnetic coagulation sedimentation tank, and a disinfection tank. Among them, the dosage of magnetic iron powder is 100g / L, the dosage of activated carbon powder is 100g / L, and the dosage ratio is 1:1. The influent water quality and removal rate of each section are shown in Table 1 below.

[...

Embodiment 2

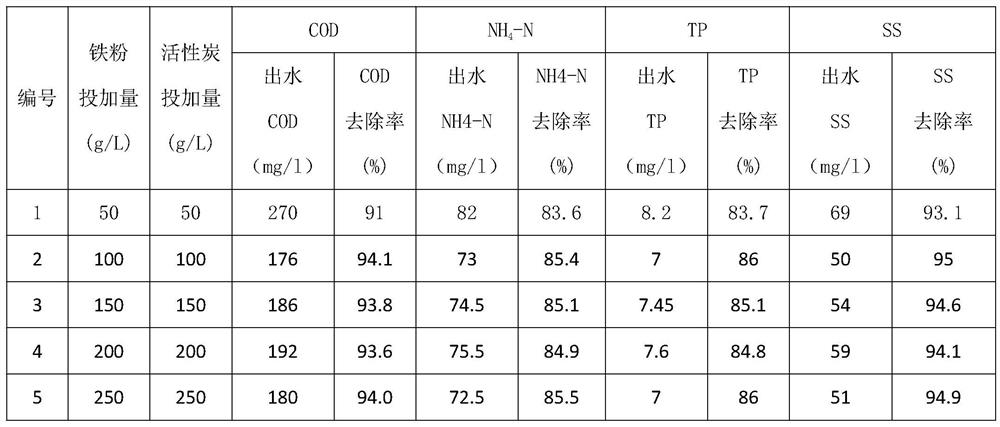

[0044] In this embodiment, the wastewater is the same breeding wastewater as in Embodiment 1, and the dosage of magnetic iron powder and activated carbon powder was changed in the laboratory test, and the experimental data obtained are shown in Table 2 below.

[0045] Table 2

[0046]

[0047] According to Table 2, it can be seen that with the increase of the dosage of magnetic iron powder and activated carbon powder (that is, the dosage is 50-100g / L), the COD, NH 4 - The removal rates of N, TP, and SS gradually increased. When the dosage of magnetic iron powder and activated carbon powder reached 100g / L respectively, the removal rate indicators of various pollutants in the system reached the peak. And when the dosage is greater than 100g / L (that is, the dosage is 100-250g / L), the removal rate of various pollutants in the system tends to be flat, and the indicators no longer rise. It can be seen that the optimal dosage of magnetic iron powder and activated carbon powder is...

Embodiment 3

[0049] In this example, the wastewater is the same breeding wastewater as in Example 1. In the laboratory test, the ratio of magnetic iron powder and activated carbon powder was changed, and the experimental data obtained are shown in Table 3 below.

[0050] table 3

[0051]

[0052] According to Table 3, under the condition that the total dosage of magnetic iron powder and activated carbon powder remains unchanged (that is, the total dosage is 200g / L), changing the mass ratio of the two substances, with the increase of Fe / C mass ratio , system COD, NH 4 - The removal rate of N, TP, and SS also increases accordingly; when the mass ratio of Fe / C is equal to 1, the removal rate of various pollutants in the system reaches the optimum, and when it is greater than this value, the treatment effect of the system will not be significantly improved .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com