Power transformation cabinet dust-settling device

A technology of dust suppression device and substation cabinet, which is applied in the directions of substation/distribution device casing, substation/switchgear cooling/ventilation, substation/switch arrangement details, etc., can solve the problems of low efficiency and large dust in the substation cabinet, etc. Achieve the effect of ensuring safety, reducing failure rate and prolonging cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

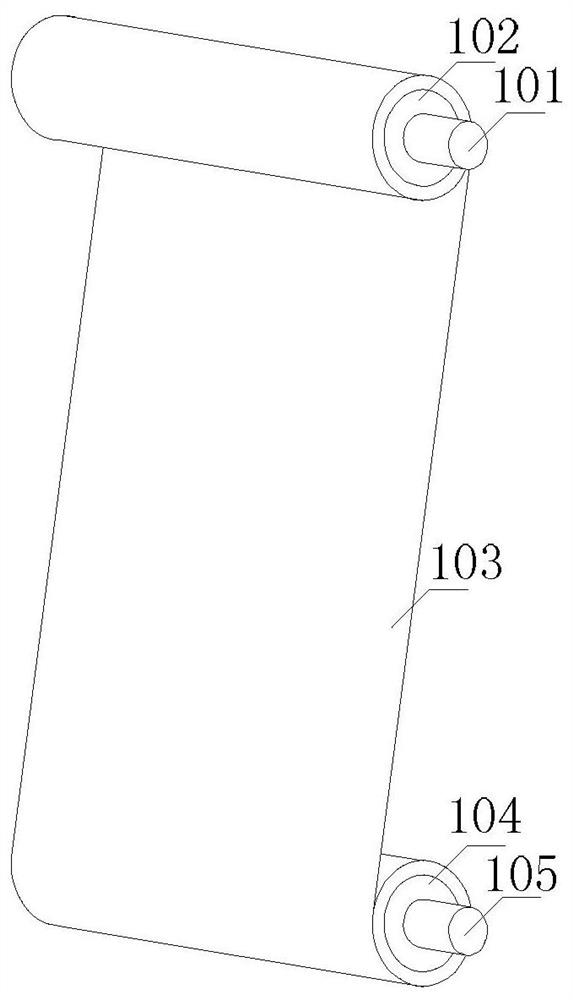

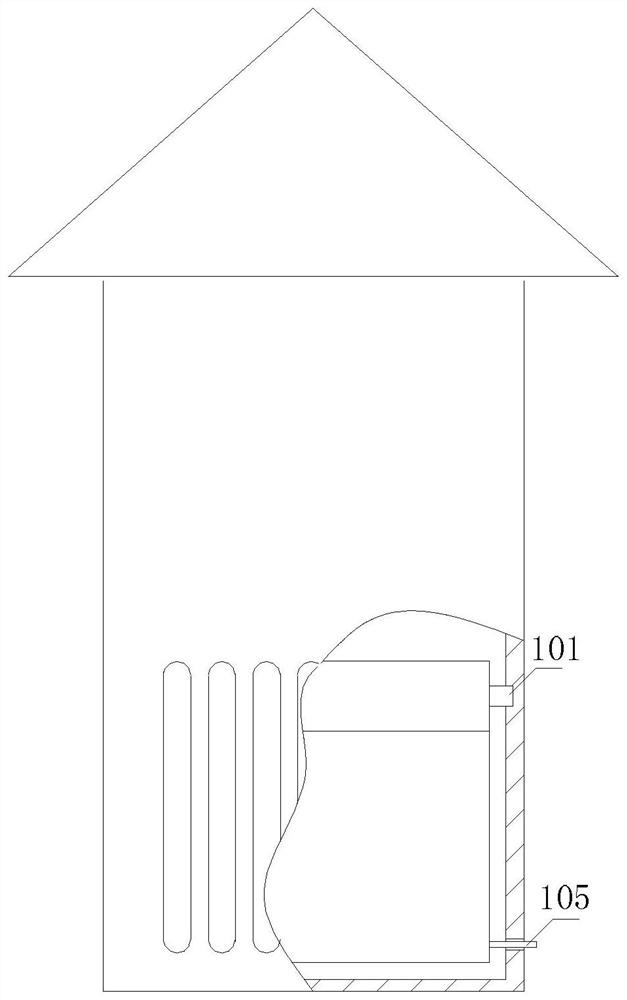

[0032] Specific implementation mode one: refer to figure 1 with figure 2 Describe this embodiment in detail. The dust suppression device for a transformer cabinet described in this embodiment includes: a support shaft 101 , a paper tube 102 , an electrostatic adsorption paper 103 , a driving roller 104 and a rotating handle 105 .

[0033] In practical application, the two ends of the support shaft 101 are respectively fixedly connected to the two opposite side walls of the transformer cabinet, so that the support shaft 101 is parallel to the side of the transformer cabinet with the ventilation opening. The paper tube 102 is sleeved on the support shaft 101 and can rotate. The electrostatic adsorption paper 103 is strip-shaped, and the head end of the electrostatic adsorption paper 103 is fixedly connected to the outer surface of the paper tube 102 , and is stacked and wound on the outer surface of the paper tube 102 to form a paper roll structure.

[0034] The driving rolle...

specific Embodiment approach 2

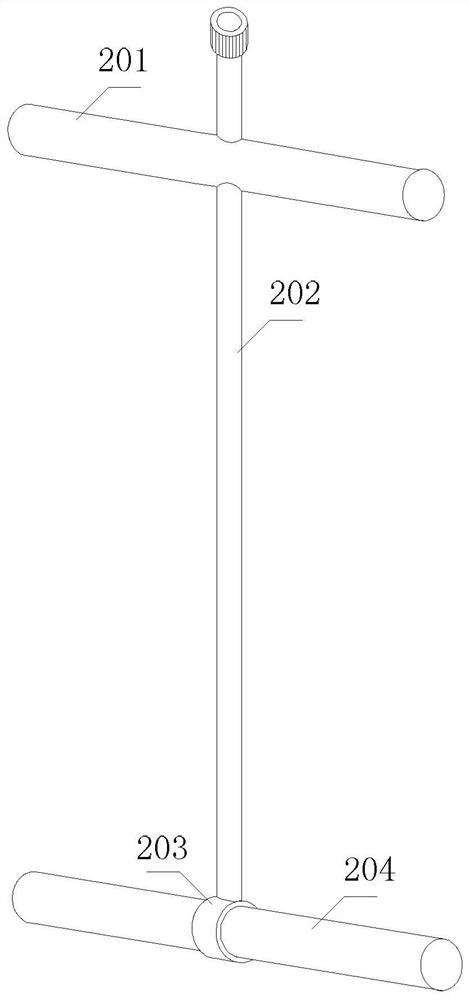

[0039] Specific implementation mode two: refer to Figure 3 to Figure 5 Describe this embodiment in detail. The dust suppression device for a transformer cabinet described in this embodiment includes: a bracket, two paper tubes 102, two sheets of electrostatic adsorption paper 103, a No. 1 motor 206, a No. 2 motor, a transmission belt 207, a controller, The motor driver, the dust sensor and the temperature sensor, and the support include: an upper cross bar 201 , a longitudinal bar 202 and a lower cross bar 204 .

[0040] The longitudinal bar 202 is perpendicular to the upper cross bar 201 and is fixedly connected with the midpoint of the upper cross bar 201. The upper cross bar 201 is close to the top of the longitudinal bar 202. The end of the longitudinal bar 202 is provided with a collar 203. The central axis of the longitudinal bar 202 The center axis of the collar 203 is perpendicular to each other. The collar 203 is sleeved on the outer surface of the lower cross bar 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com