Low-pressure egr system with turbo bypass

A technology of turbines and conduction systems, applied in charging systems, mechanical equipment, engine components, etc., can solve the problems of low oxygen content, inability to fully burn the quality of filter particles, and achieve the effect of achieving effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

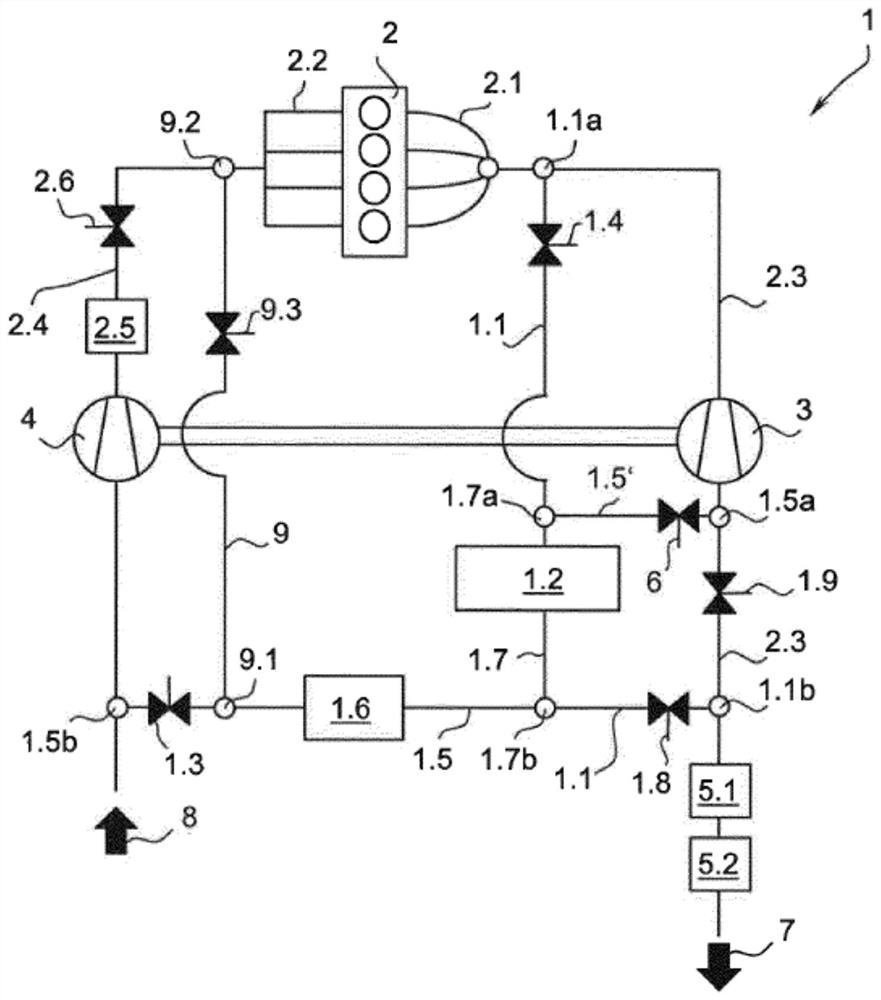

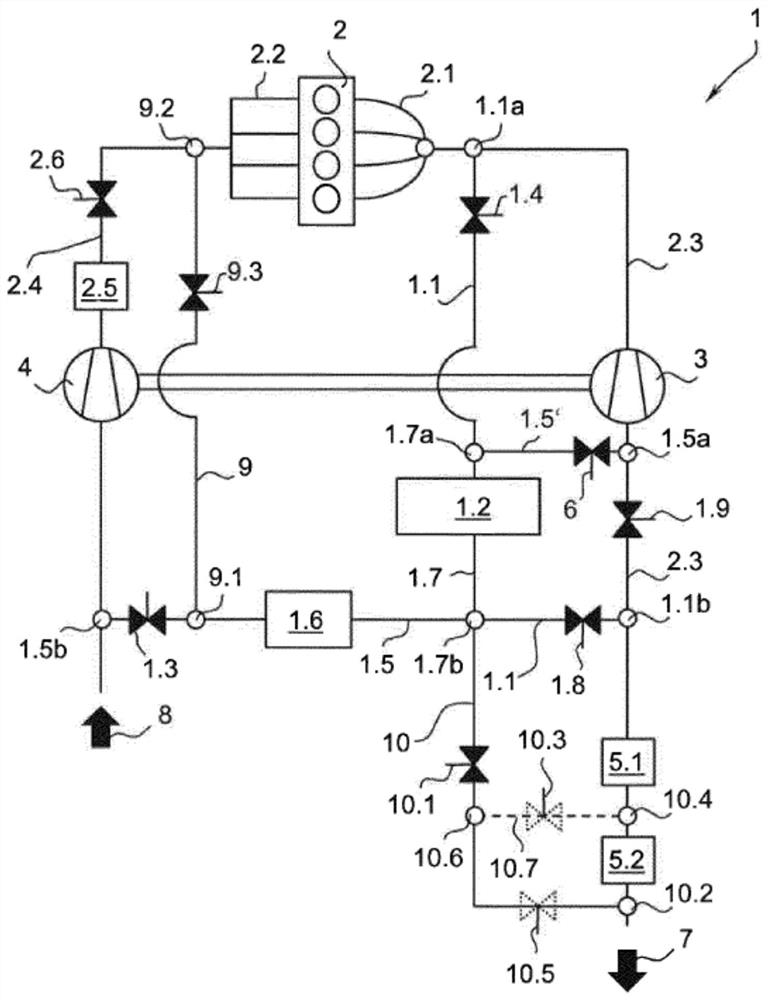

[0030] in accordance with Figure 1 to Figure 3In all the schematic diagrams of the exemplary embodiments shown, an exhaust gas conduction system 1 (EGR system) is shown which is integrated into a system with an exhaust manifold 2.1 and an intake manifold 2.2 and with an exhaust gas turbine 3 and a booster Compressed air compressor 4 in the exhaust gas and charge air system of the gasoline engine 2. The exhaust gas and charge air system has an exhaust gas line 2.3, which is connected to the exhaust manifold 2.1 of the gasoline engine 2, in which the turbine 3 is integrated. At the end of the exhaust gas line 2.3, the exhaust gas 7 leaves the exhaust system 1 and flows into an additional exhaust gas path, not shown. In addition, the present invention also provides an intake line 2.4, which is connected to the intake manifold 2.2 of the gasoline engine 2, in which the compressor 4 is integrated. The intake line 2.4 is supplied with fresh air 8 via an intake system not shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com