Preparation method of hyperstable self-supported manganese dioxide water treatment membrane

A manganese dioxide film and manganese dioxide technology are applied in the fields of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., which can solve the problems of poor stability and easy dispersion of manganese dioxide film, and achieve broad industrial applications Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the preparation method of a kind of ultra-stable self-supporting manganese dioxide water treatment membrane of the present embodiment is carried out according to the following steps:

[0022] 1. Evenly disperse manganese dioxide in deionized water to obtain a dispersion, then place the filter membrane in a negative pressure suction filtration device, and then use a negative pressure suction filtration device with a filter membrane to filter the dispersion liquid, Finally, a manganese dioxide film layer is obtained on the surface of the filter membrane;

[0023] The concentration of manganese dioxide in the dispersion liquid described in step 1 is 0.5g / L~1g / L;

[0024] The thickness of the manganese dioxide film layer described in step 1 is 10 μm to 50 μm;

[0025] Two, add oxidizing agent in cross-linking agent, obtain the mixed solution of oxidizing agent and cross-linking agent after mixing evenly, then pass the mixed solution of oxidizing ag...

specific Embodiment approach 2

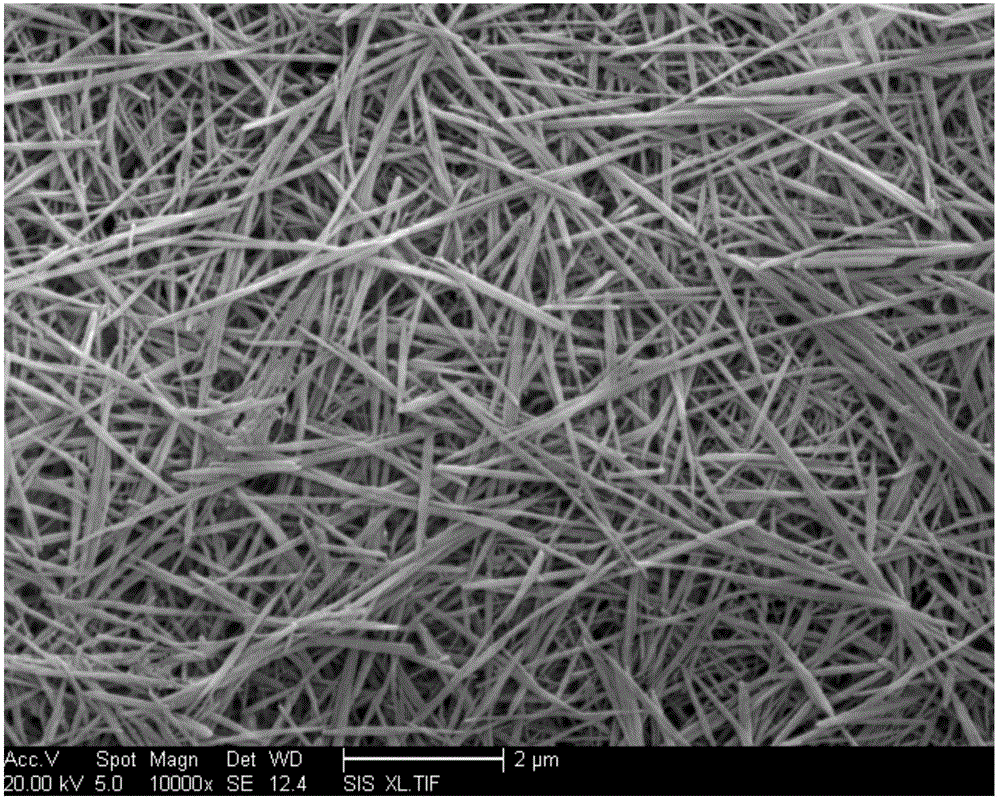

[0033] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the microscopic morphology of manganese dioxide described in step 1 is one or more of linear, rod, hollow tubular, fibrous and lamellar. combination. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the size specification of the linear manganese dioxide is: a diameter of 10 nm to 30 nm, and a length of 10 μm to 20 μm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com