Building block type cylindrical condenser

A cylindrical condenser technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of low sealing performance and pressure bearing capacity, unsuitable for small power stations, poor structural versatility, etc., to achieve Good sealing performance, saving design and manufacturing cycle, small floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

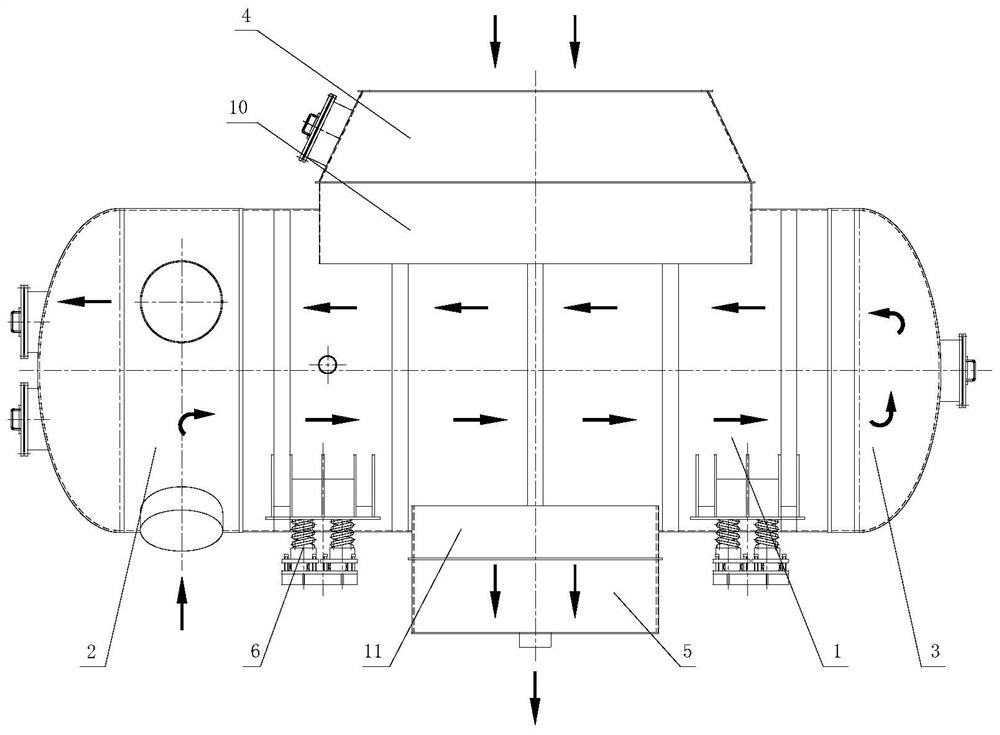

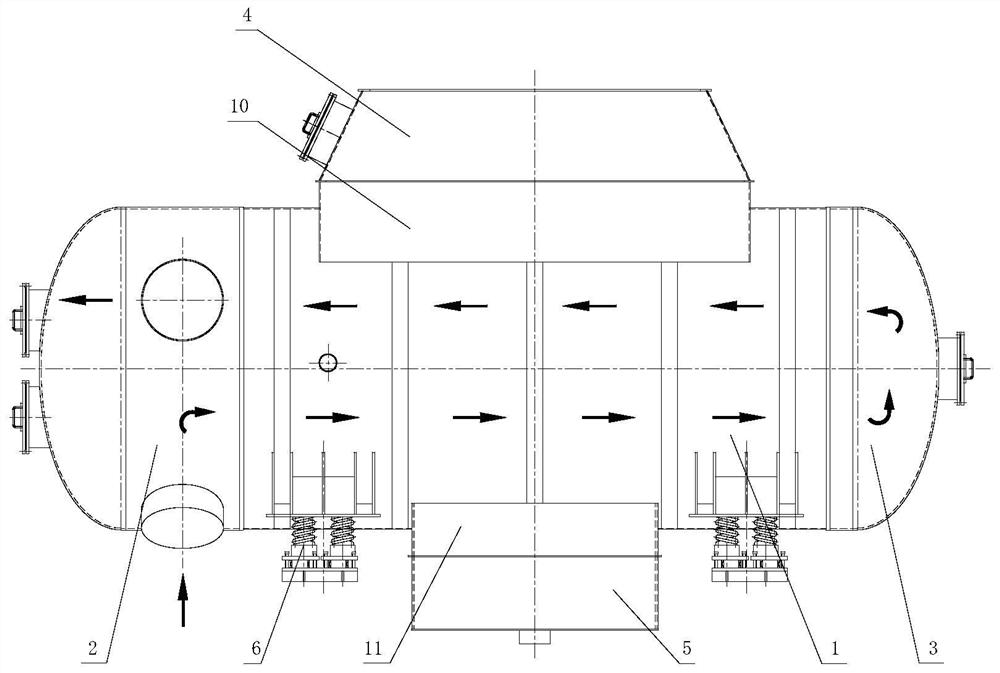

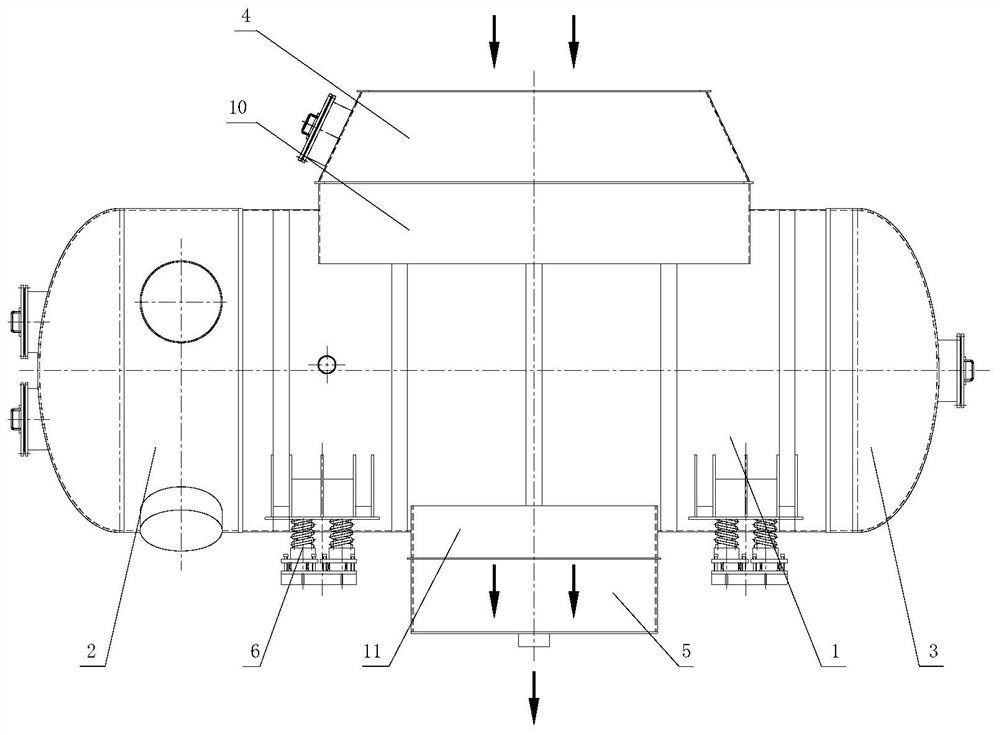

[0026] Specific embodiment 1: It includes a shell 1, an inlet and outlet water chamber 2, a return water chamber 3, an exhaust throat 4, a hot well 5 and a plurality of shock-absorbing support seats 6;

[0027] The inlet and outlet water chamber 2 is arranged at one end inside the shell 1, the return water chamber 3 is arranged at the other end inside the shell 1, the exhaust throat 4 is arranged at the upper part of the shell 1, and the hot well 5 is arranged at the shell In the lower part of the body 1 , a plurality of shock-absorbing support seats 6 are arranged on the bottom of the housing 1 .

[0028] The shell 1 is arranged with a tube bundle composed of a tube plate, heat exchange tubes and heat exchange tube support plate, the heat exchange tube support plate is fixed inside the shell 1, and the heat exchange tubes are connected and fixed through the tube plate. The support plate is evenly arranged inside to avoid the vibration of the tube bundle.

[0029] In this emb...

specific Embodiment approach 2

[0032] Embodiment 2: The casing 1 is cylindrical.

[0033] Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0034] Specific implementation mode three: both the inlet and outlet water chambers 2 and the return water chamber 3 adopt a head structure.

[0035] In this embodiment, both the inlet and outlet water chambers 2 and the return water chamber 3 adopt a head structure, and communicate with the inner cavity of the heat exchange tube at the same time.

[0036] Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com