Press-fitting equipment for evaporator

A technology for pressing equipment and evaporators, which is applied to evaporators/condensers, mechanical equipment, lighting and heating equipment, etc. The effect of labor intensity, high bonding efficiency and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

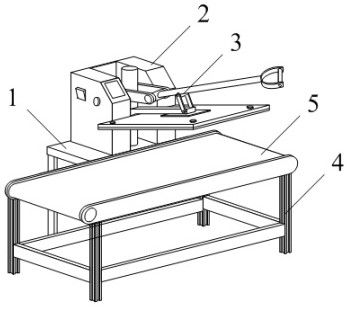

[0024] as attached figure 1 to attach image 3 shown

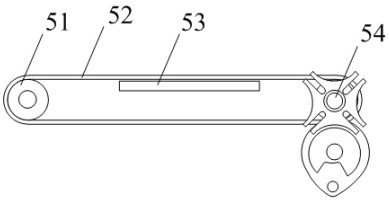

[0025] The present invention provides an evaporator pressing device, which includes a frame body 1, a casing 2, a pressing mechanism 3, a transmission bracket 4 and an intermittent transmission device 5, and the upper part of the frame body 1 is fixed by bolts to the organic casing 2. A pressing mechanism 3 is detachably connected to the inside of the casing 2 ; an intermittent transmission device 5 is provided on the transmission bracket 4 ;

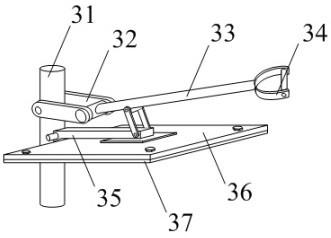

[0026] The pressing mechanism 3 includes a column 31, a movable connecting frame 32, a lower pressing rod 33, a handle 34, a movable assembly 35, a fixed plate 36 and a pressing plate 37, and the column 31 is vertically installed on the frame body 1 by bolts. The upper end, the column 31 is located in the middle of the casing 2; the two ends of the movable connecting frame 32 are respectively movably connected with the column 31 and the lower pressing rod 33 through pin shafts; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com