Diaphragm valve

A diaphragm valve, diaphragm technology, applied in the direction of diaphragm valve, lift valve, diaphragm, etc., can solve the problem that the valve cannot do anything, and achieve the effect of ensuring the sweeping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

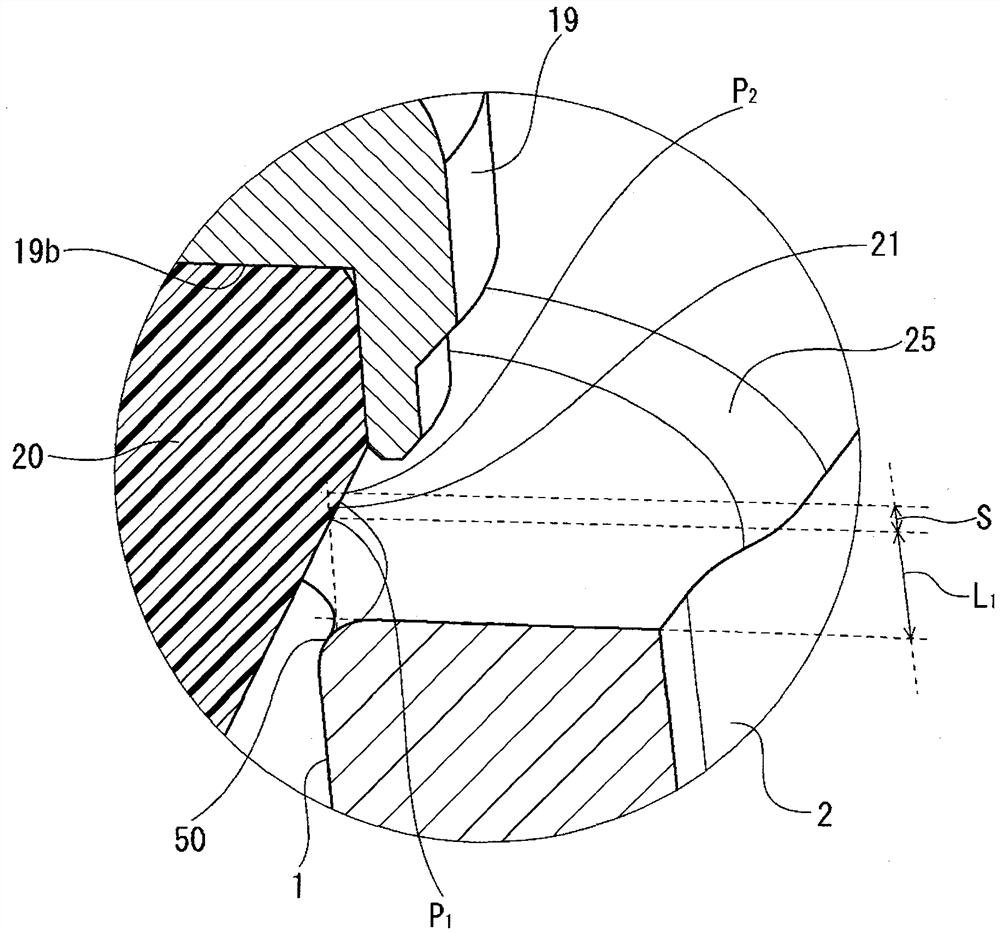

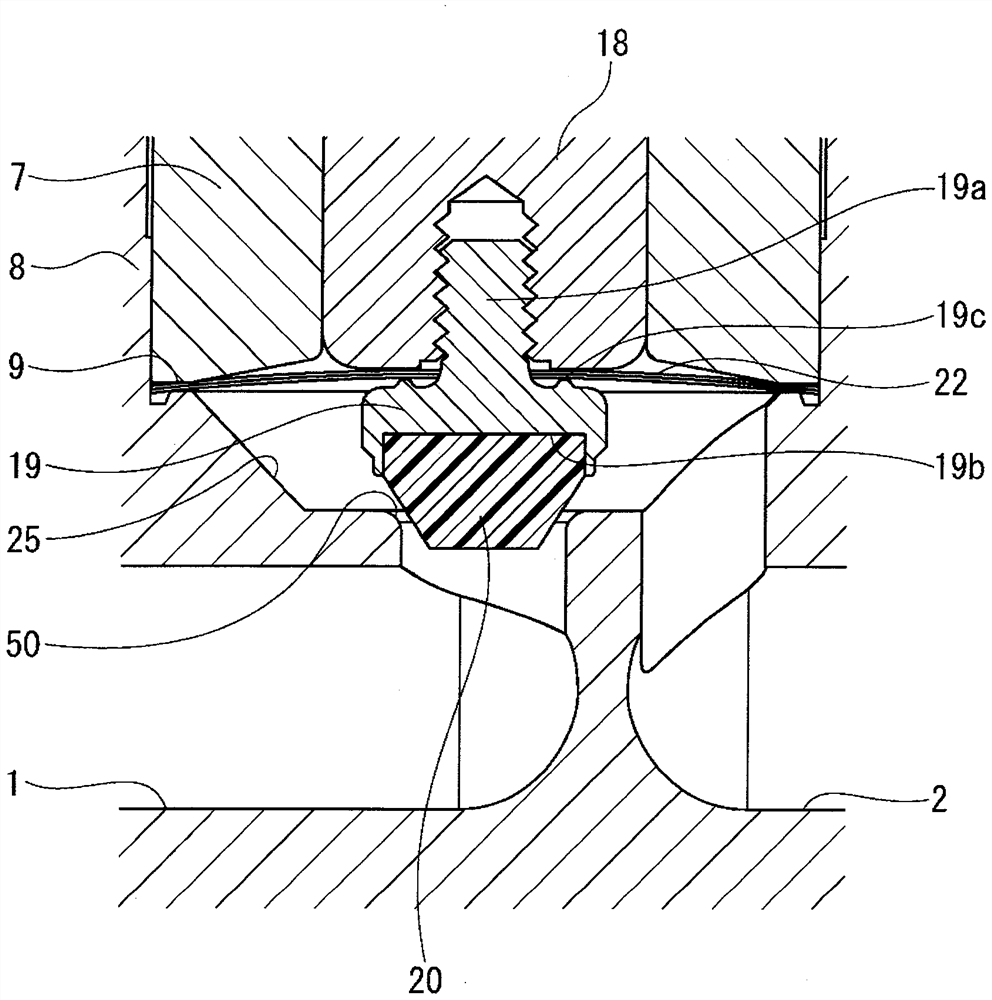

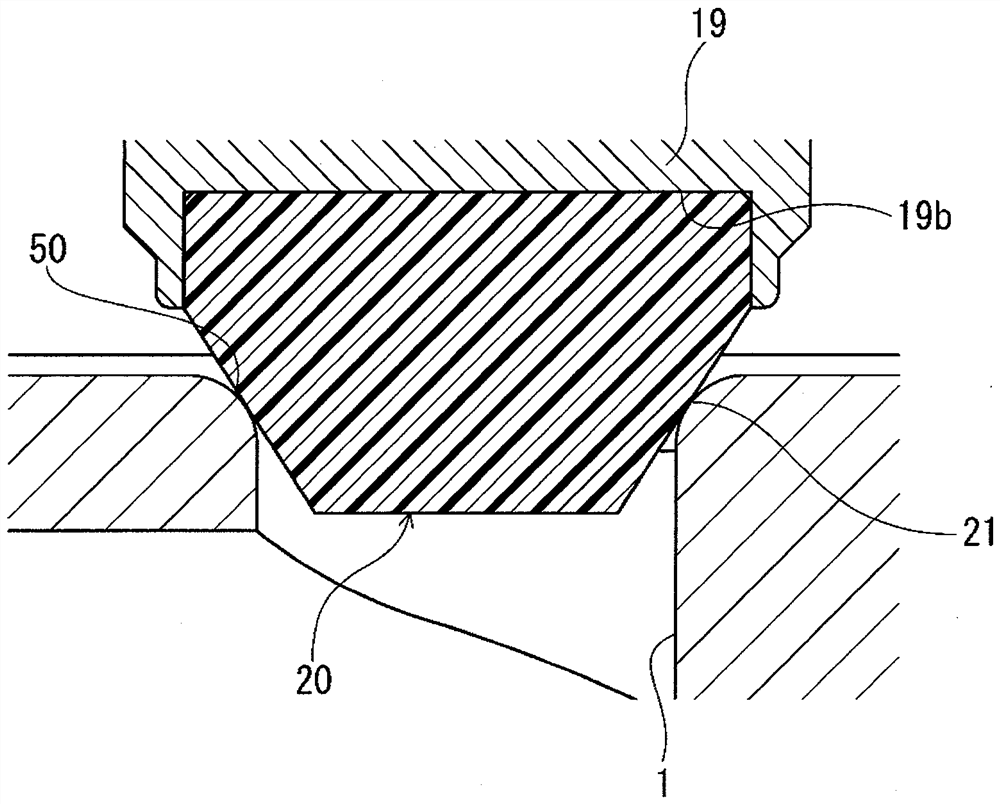

[0044] Hereinafter, the structure of one embodiment (this example) of the present invention will be described in detail based on the drawings. figure 1 It is a longitudinal sectional view showing the fully open state of the diaphragm valve of this example, and first, the overall structure of the valve will be described. In addition, the valve of this figure uses the 2nd sheet|seat 30 as mentioned later.

[0045] exist figure 1 Among them, the main body 3 (valve box) is formed of an integral metal member, and the primary side flow path 1 and the secondary side flow path 2 are linearly pierced. The primary side flow path 1 faces the valve chamber provided in the valve box. 25 communicates through the primary side opening edge, and the secondary side flow path 2 opens in this valve chamber 25 . In the upper part of the valve chamber 25, the cylindrical part 8 is provided, and the outer peripheral surface of this cylindrical part 8 is provided with the male thread part 8a.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com