Efficient roof truss turnover system

An efficient and systematic technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of high risk of prefabricated roof truss turning over, damage to prefabricated roof trusses, unfavorable saving of construction period, etc., to reduce the risk of roof truss turning over, save construction period, The effect of improving the utilization rate of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

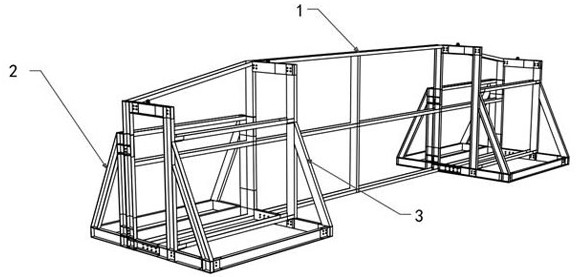

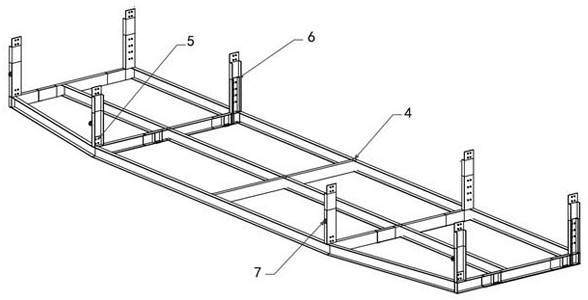

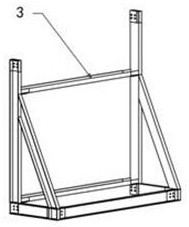

[0024] Such as Figure 1 to Figure 6 A roof truss high-efficiency turning system of the present invention is shown, including a turning chassis 1 for clamping the roof truss, a right support frame 3 for supporting the right side of the turning chassis 1, and a left support frame 3 for supporting the left side of the turning chassis 1. The support frame 2, the right support frame 3 and the left support frame 2 are all right-angle support frames; the turn-over chassis 1 is composed of a net frame 4 and one or more connecting devices; the connecting device is welded and fixed on the net frame 4 The right side is used to clamp the roof truss; one right-angled surface of the right support frame 3 is detachably connected with the connecting device (through bolts) to form a closed body and then the roof truss is clamped, and the other right-angled surface is flush with the bottom surface of the grid frame 4 (to support the right side of the turn-over chassis 1); after the turn-over o...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is:

[0030] The number of the connecting device is one and is arranged on the middle part of the right side of the network frame 4, and four connecting pieces 5 are evenly arranged on the middle part of the right side of the network frame 4. In order to ensure the supporting effect, the two connecting pieces 4 at the front end The spacing between the two connecting pieces 4 at the rear end is large, and the number of the right support frame 3 connected correspondingly to it is also one. Simultaneously, the number of said left support frame 2 is one and is arranged on the middle part of the left side of the grid frame 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com