Wide temperature range self-lubricating vn-ag 2 moo 4 Composite material and its preparation method

A technology of vn-ag2moo4 and composite materials, which is applied in the field of wide temperature range self-lubricating VN-Ag2MoO4 composite materials and its preparation, can solve the problems that self-lubricating composite materials cannot meet the requirements of use, etc., and achieves easy production amplification, tight integration and improvement. The effect of friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

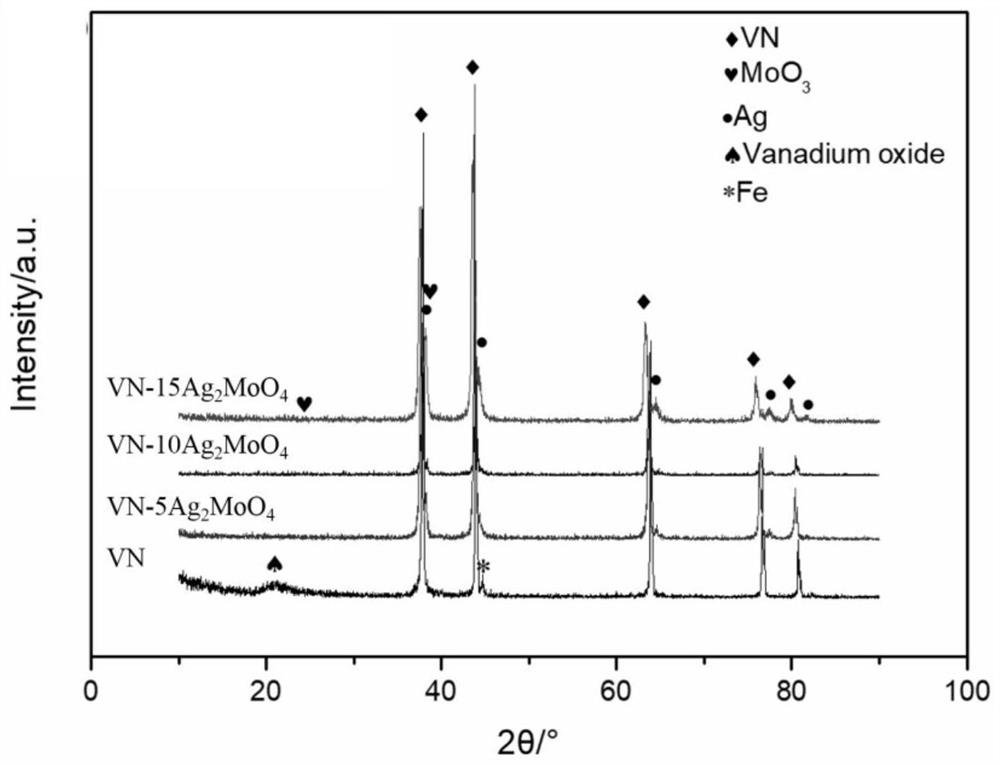

Image

Examples

preparation example Construction

[0033] A method for preparing a nickel-based self-lubricating composite material in a wide temperature range, comprising the steps of:

[0034] 1) Weigh 85-95% of VN powder and 5-15% of Ag by weight 2 MoO 4 powder, to obtain the original ingredient;

[0035] 2) Using a planetary ball mill to perform mechanical alloying of the original ingredients to obtain a uniform mixed powder;

[0036] 3) Put the mixed powder into a graphite abrasive tool, and prepare it by hot pressing and sintering technology under vacuum protection to obtain a continuous self-lubricating composite material in a wide temperature range.

[0037] The VN powder is purchased from the market with an average particle size of 15 μm; the Ag 2 MoO 4 The powder is chemically synthesized or purchased from the market, with an average particle size of 10 μm.

[0038] As a further improvement of the above preparation method, the ball-to-material ratio in the ball milling process in step 2) is 3:1-5:1, the ball-milli...

Embodiment 1

[0041] Embodiment 1 The wide temperature range self-lubricating VN-Ag 2 MoO 4 Composite material and preparation method thereof, carry out according to the following steps:

[0042] (1) According to VN powder mass fraction is 90%, Ag 2 MoO 4 The massfraction of powder is the ratio batching of 10%, weighs 90 grams of silver powder and Ag 2 MoO 4 Powder 10 grams obtains original batching, wherein the average particle diameter of VN powder is 15 μ m, Ag 2 MoO 4 The average particle size of the powder is 10 μm;

[0043] (2) The original ingredients are placed in a planetary ball mill, and the ball-to-material ratio is 3:1, the rotating speed is 100r / min, and the ball mill is mixed for 10 hours to obtain evenly mixed sintered ingredients;

[0044] (3) Put the sintering ingredients into a graphite mold, and carry out hot-press sintering in a vacuum environment, wherein the sintering temperature is 1650°C, the heating rate is 5°C / min, the sintering pressure is 20MPa, and the h...

Embodiment 2

[0045] Example 2 Wide temperature range self-lubricating VN-Ag 2 MoO 4 Composite material and preparation method thereof, carry out according to the following steps:

[0046] (1) According to VN powder mass fraction is 95%, Ag 2 MoO 4 The massfraction of powder is the ratio batching of 5%, weighs 95 grams of silver powder and Ag 2 MoO 4 5 grams of powder to obtain the original ingredients, wherein the average particle size of VN powder is 15 μm, Ag 2 MoO 4 The average particle size of the powder is 10 μm;

[0047] (2) The original ingredients are placed in a planetary ball mill, and the ball-to-material ratio is 5:1, the rotating speed is 300r / min, and the ball mill is mixed for 5 hours to obtain evenly mixed sintering ingredients;

[0048] (3) Put the sintering ingredients into a graphite mold, and perform hot-press sintering in a vacuum environment, wherein the sintering temperature is 1700°C, the heating rate is 10°C / min, the sintering pressure is 20MPa, and the hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com